Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

Ever wondered what makes certain materials so incredibly hard? Tungsten carbide is one of them. This remarkable material is known for its extreme hardness, making it essential in industries that require durability. In this post, we'll explore why tungsten carbide is so hard, how it compares to other materials, and its many industrial applications.

Tungsten carbide's extreme hardness comes from its unique composition and the process used to make it.

Tungsten carbide is a combination of tungsten and carbon. Tungsten is a metal with high density, and carbon is a non-metal. Together, they form a compound that is incredibly hard and durable.

The tungsten atoms form strong bonds with the carbon atoms. This tight structure makes it resistant to scratching, abrasion, and wear. The result is a material that ranks high on the Mohs scale of hardness (about 9), just behind diamonds.

To make tungsten carbide tougher, manufacturers add cobalt or nickel as binders. These materials hold the tungsten carbide grains together, giving the compound better toughness. While the carbide itself is hard, the binder helps prevent the material from breaking under stress.

Creating tungsten carbide isn't just about mixing the right materials; the manufacturing process plays a big role.

Tungsten carbide is made through a process called sintering. In this process, the tungsten and carbon are heated to high temperatures, causing them to bond tightly together. This high-temperature step increases the material's density, making it even harder.

The hardness of tungsten carbide also depends on how fine the tungsten grains are. Smaller grains create a denser structure, which results in higher hardness. The amount of binder used can also affect its toughness. Too little binder makes it harder but more brittle, while too much binder can reduce its hardness.

Tungsten carbide is one of the hardest materials used in industries today. Let's see how it measures up against other hard materials.

The Mohs scale measures how resistant a material is to scratching. It ranks materials from 1 (talc) to 10 (diamond). Tungsten carbide stands at 9 on this scale. That's just behind diamond, the hardest natural material.

The Mohs scale is based on the ability of one material to scratch another. Higher numbers indicate harder materials. A material with a hardness of 9 (like tungsten carbide) can scratch anything softer than it.

● Diamond: Mohs rating of 10. The hardest known material.

● Tungsten Carbide: Mohs rating of 9. Extremely hard, only surpassed by diamond.

● Steel: Mohs rating of around 4-5. Much softer than tungsten carbide.

● Glass: Typically 5.5 on the Mohs scale. Also much softer than tungsten carbide.

To measure hardness more precisely, we use Rockwell and Vickers hardness tests. These tests are commonly used in industrial settings.

On the Rockwell C scale (HRC), tungsten carbide typically falls between 69 and 82. This is a high rating, showing its ability to resist wear and deformation under stress.

Vickers hardness (Hv) measures how much pressure is needed to create an indentation in a material. Tungsten carbide has a Vickers hardness of about 2400 Hv, which means it can withstand extreme pressure without getting damaged.

Hardness tests are crucial for understanding how a material will perform under certain conditions. Whether it's cutting, drilling, or resisting wear, these tests help ensure that the right material is used for each task.

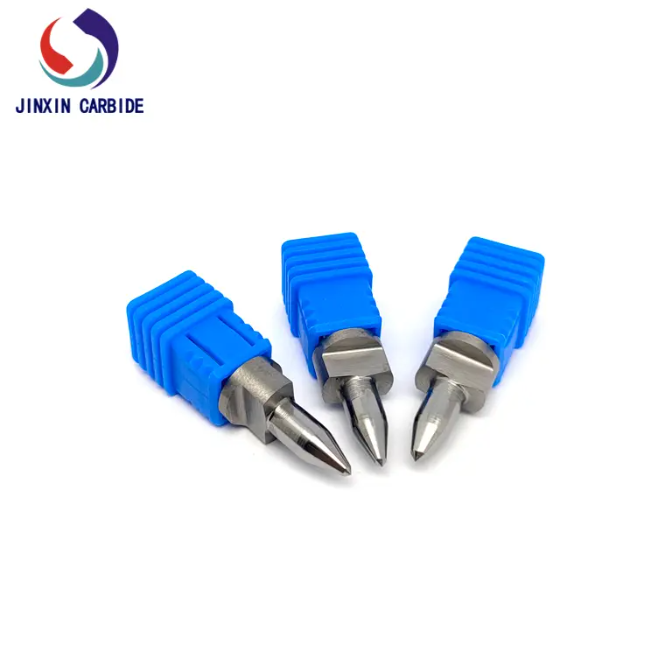

Tungsten carbide's extreme hardness makes it ideal for industrial tools like drills, end mills, and saw blades. These tools stay sharp and precise, even under heavy use, due to tungsten carbide's ability to resist wear. Compared to tools made from softer metals, those made with tungsten carbide last much longer, reducing the need for frequent replacements and minimizing downtime in industries requiring high-performance tools.

Tungsten carbide is widely used in mining and drilling equipment, especially for drill bits and mining tools. Its hardness allows these tools to withstand high pressure and abrasive conditions, allowing them to cut through tough rocks and minerals without losing their shape or sharpness. This makes it the material of choice in industries where tools are subjected to extreme environments and must maintain durability over time.

Tungsten carbide's durability and resistance to wear make it perfect for aerospace applications. It is used in aerospace components where it protects parts from wear, especially in high-temperature and high-pressure environments. The material's strength also makes it a popular choice for jewelry, particularly wedding bands, as it resists scratching and maintains a polished finish, making it ideal for long-lasting, durable pieces.

Tungsten carbide is incredibly hard, but is it as hard as diamond? Let's break it down.

Diamond is the hardest natural material on Earth, ranking 10 on the Mohs scale of hardness. Tungsten carbide, while incredibly tough, is slightly less hard, sitting at a 9 on the same scale.

On the Mohs scale, diamond is the top contender, making it harder than tungsten carbide. However, the difference between a 9 and a 10 is quite small in practical terms. Tungsten carbide can scratch almost any material except diamond, which makes it suitable for many industrial applications.

Despite diamond's superior hardness, tungsten carbide still plays a vital role in industrial settings. Diamond is often too expensive and fragile for some uses, while tungsten carbide offers great hardness at a more affordable price. Tungsten carbide tools, for instance, are tough enough to handle high-pressure environments, yet they are more durable than diamond in situations involving impact or shock.

Tungsten carbide remains a crucial material in industries such as mining, manufacturing, and aerospace. While diamond may be the hardest material, it can also be brittle, making it unsuitable for certain applications. Tungsten carbide, on the other hand, offers a combination of hardness and toughness, making it ideal for tools that require both durability and strength.

Tungsten carbide is known for its extreme hardness, but it also has some impressive mechanical properties that make it stand out in many industries.

Tungsten carbide isn't just hard—it's also incredibly strong. Its tensile strength means it can withstand a lot of pressure without breaking. This makes it ideal for applications that require both strength and durability. Unlike materials that might crack or shatter under stress, tungsten carbide maintains its shape even in harsh environments.

While tungsten carbide is extremely hard, its strength and toughness also help it resist impact. Unlike diamond, which can be very hard but brittle, tungsten carbide can absorb shock without cracking or chipping. This combination of hardness and impact resistance makes it the go-to material for tools that experience high impact or stress, like drill bits or cutting tools.

Tungsten carbide's hardness gives it incredible wear resistance. It can resist abrasion and maintain its shape over long periods of use, making it perfect for parts that experience constant friction.

The hardness of tungsten carbide means that it doesn't wear down easily. When used in industrial tools, it maintains its cutting edge longer than other materials, reducing the need for frequent replacements. This longevity is especially important in high-volume industries like mining and manufacturing, where downtime and replacement costs can add up quickly.

Tungsten carbide's durability allows it to last far longer than many other materials. It outlasts metals like steel and even some ceramics. This is why it's used in parts that undergo significant wear, such as cutting tools, mining equipment, and automotive components.

The hardness of tungsten carbide is influenced by several factors, including grain size and binder content. These elements determine how well the material resists wear and maintains its shape under stress.

Grain size plays a crucial role in tungsten carbide's hardness. Smaller grains lead to a denser structure, which in turn increases hardness. When the grains are finer, they pack together tightly, making the material more resistant to wear and deformation. However, there's a trade-off: while finer grains increase hardness, they can also make the material more brittle, reducing its toughness. So, we need to find a balance depending on the application.

The binder material, often cobalt, is another key factor in tungsten carbide's hardness. Less cobalt increases hardness but makes the material more brittle. On the other hand, more cobalt improves toughness but may reduce overall hardness. We should adjust the binder content depending on the intended use, aiming to achieve the right balance between hardness and toughness. For tools that need to withstand high wear, less binder might be used, whereas for tools exposed to impacts, more binder helps improve durability.

Testing the hardness of tungsten carbide is essential to understand how it will perform in different industrial applications. Several methods can be used, each providing valuable insights into the material's resistance to wear, abrasion, and deformation.

Three common tests are used to measure the hardness of tungsten carbide: Rockwell, Vickers, and Mohs. The Rockwell test is often used for materials like tungsten carbide, especially with the HRC (Rockwell C) scale, which measures hardness based on how deep a diamond cone penetrates the material. The Vickers test uses a diamond pyramid indenter and measures the size of the indentation to calculate hardness. It's especially useful for materials with high hardness. The Mohs scale measures the ability of a material to resist scratching, ranking from 1 (softest) to 10 (hardest), where tungsten carbide ranks at 9.

Accurate hardness measurement is crucial because it helps manufacturers determine whether the material is suitable for specific applications. For example, tools that need to cut through hard metals or minerals must have a certain hardness level to perform effectively. Incorrect hardness levels can lead to premature wear or failure of tools, which can be costly in industrial settings.

In addition to standard tests, microhardness testing plays a role in measuring the hardness of coatings or thin layers applied to tungsten carbide. This test uses a smaller indenter and applies less force, making it ideal for testing surface coatings, which might not be as thick or as hard as the core material.

Advanced coatings can significantly boost the hardness of tungsten carbide for specific applications. For example, coatings like titanium nitride (TiN) can improve wear resistance, making tools last even longer in high-performance environments. These coatings are especially important in cutting tools and machinery that face extreme conditions.

Tungsten carbide's hardness makes it irreplaceable in many industries. Its unique properties—like wear resistance and toughness—ensure it performs well in demanding applications. As industries evolve, tungsten carbide will continue to play a key role in high-performance tools and specialized applications. Its durability and strength make it an essential material for the future. Welcome to Jingxin Consulting Products!

A: Yes, tungsten carbide can withstand extremely high temperatures, making it ideal for high-speed cutting tools and aerospace components.

A: While tungsten carbide is more expensive than many other metals, its long-lasting durability and performance make it cost-effective in the long run.

A: Yes, but due to its hardness, it requires specialized equipment like diamond tools or grinding methods to shape or machine tungsten carbide.

A: While tungsten carbide is hard, it can be brittle under certain conditions, especially with low binder content, which makes it prone to cracking under impact.

A: Tungsten carbide excels in high-pressure conditions, maintaining its hardness and shape, making it ideal for applications in mining, drilling, and cutting.