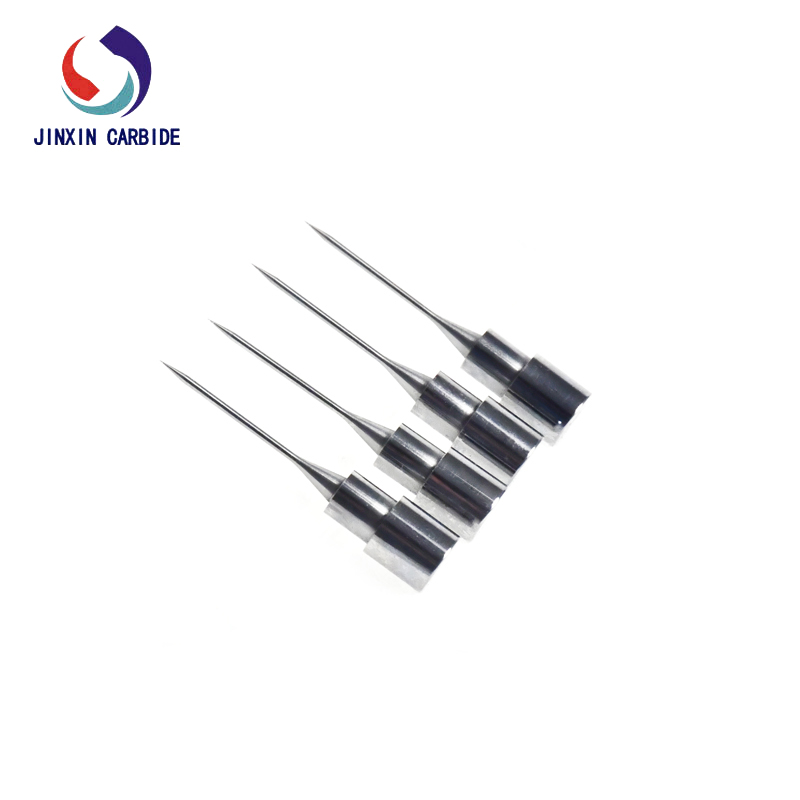

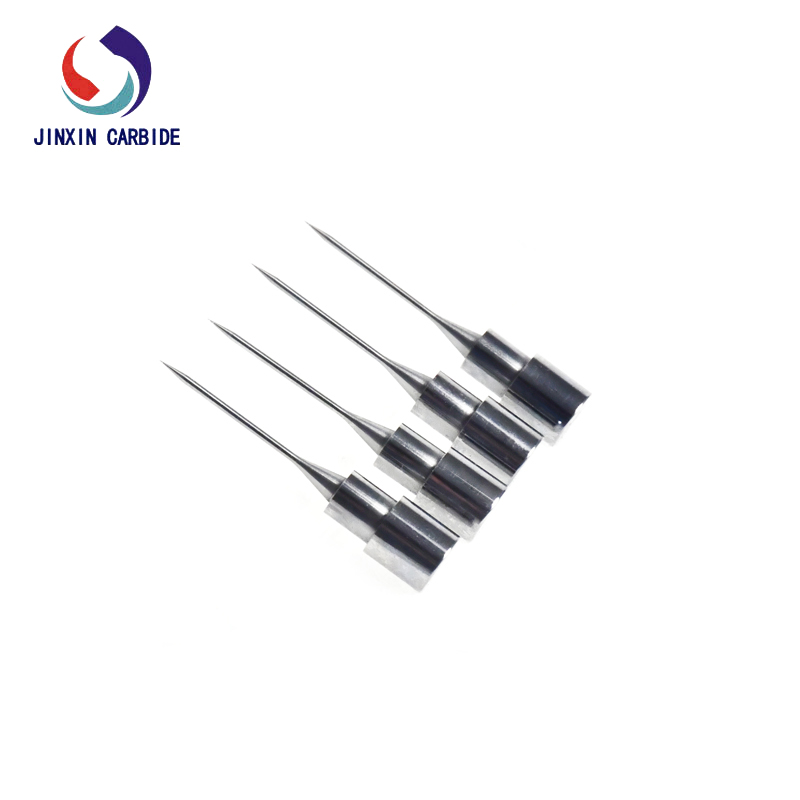

Tungsten Carbide punch Pins description

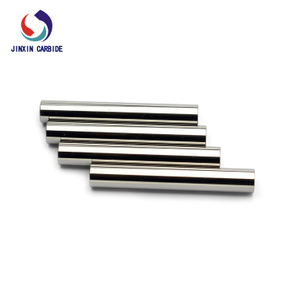

Tungsten carbide is a major component of cemented carbide materials. As hard phase of refractory metal, the tungsten steel is used with transition metal (Co, etc.) as the binder phase. The super-hard material prepared by powder metallurgy technology is cemented carbide. Cemented carbide has the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance and small coefficient of linear expansion.

It is one of the excellent tool materials, widely used in many industrial production and processing operations. Especially for the use of precision mold equipment, such as the tungsten carbide punch pin used in the AR8 anti-vibration rotor core stamping mold. Material performance is the basic use requirement, and long-lasting life is the efficiency guarantee for industrial mass production.

Tungsten carbide punch pins Applications

Tooling: Used in various cutting and machining tools where hardness and wear resistance are critical.

Electronics: Often used as contact pins in electrical connectors due to their durability and conductivity.

Medical: In surgical instruments and dental tools where precision and durability are essential.

Oil and Gas: Used in drilling and exploration equipment due to their ability to withstand abrasive environments.

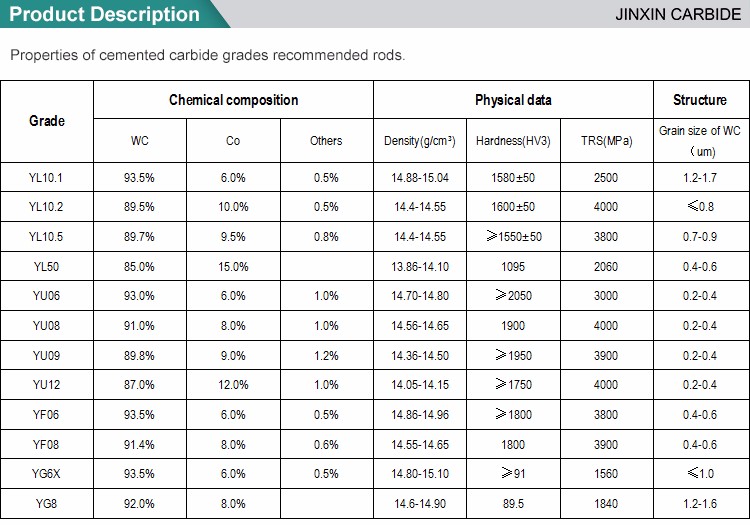

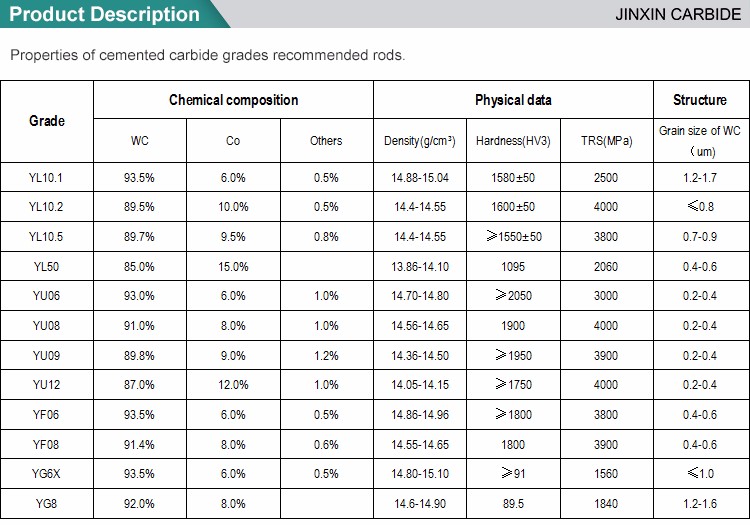

Tungsten carbide punch pins physical parameters

The physical parameters of conventional tungsten carbide non-standard forming pin

production materials can be referred to as follows:

* Grain size (um): 0.8 ~ 2.0

* Cobalt content (Co%): 6 ~ 10

* Density (g/cm³): 14.45

* Hardness (HRA): 88 ~ 92

* Bending strength (Mpa): 3200 ~ 3800

* Young's modulus (Gpa): 570

* Compressive strength (Mpa): 4700

Tungsten carbide punch pins specification

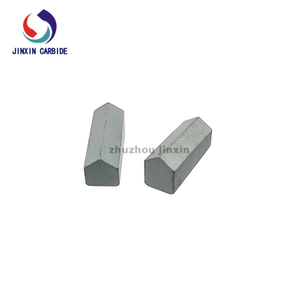

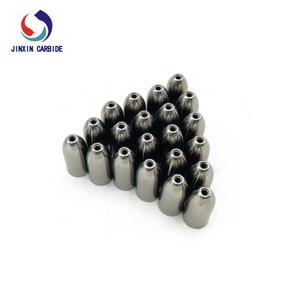

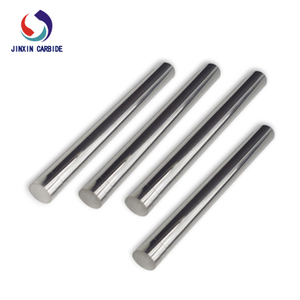

Tungsten carbide punch pins photos

+86-18073319589

+86-18073319589