- Home

- Tungsten Carbide

- Tungsten Carbide Rotary Burrs

- Tungsten Carbide Ball

- Tungsten Carbide Rods

- Tungsten Carbide Plate & Strip

- Tungsten Carbide Ring

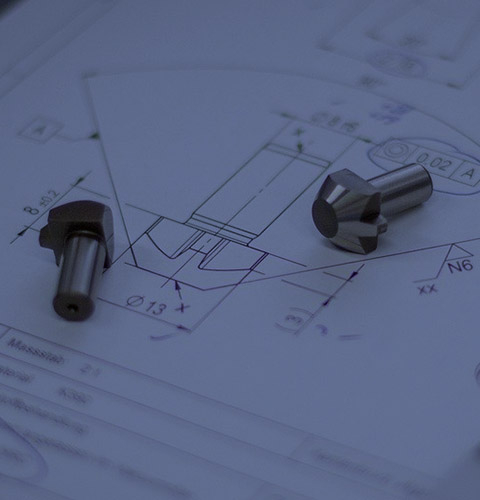

- Tungsten Carbide Cutting Tools

- Tungsten Carbide Roller

- Tungsten Carbide Studs

- Tungsten Carbide Mould

- Tungsten Carbide Tip

- Tungsten Carbide Wear Parts

- Custom Ceramic Parts

- Carbide Friction Drill

- Tungsten Alloy

- Tire Studs

- About Us

- News

- Vedio of Factory

- Contact Us

+86-18073319589

+86-18073319589