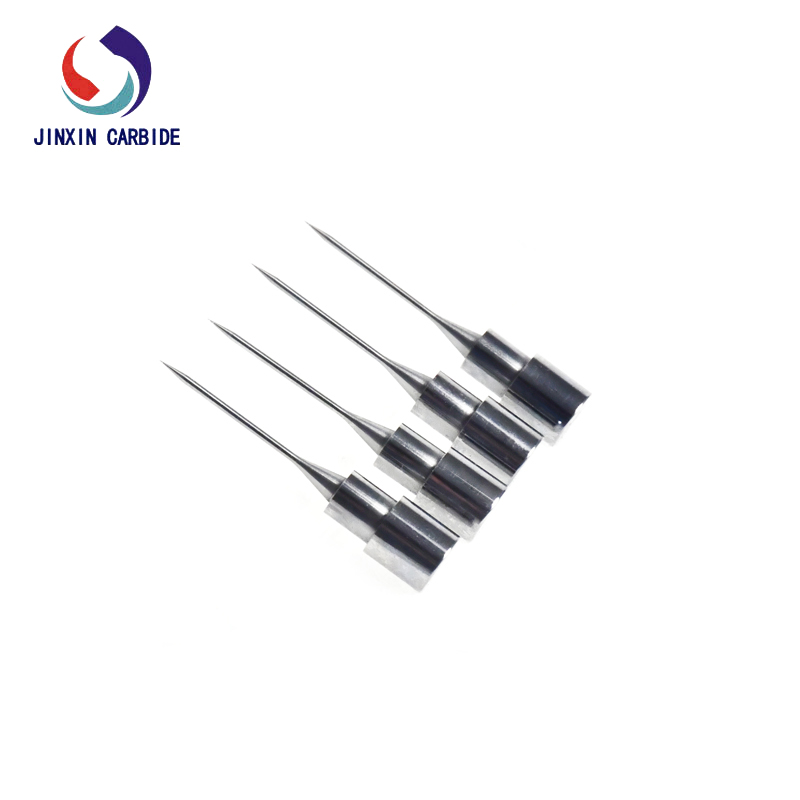

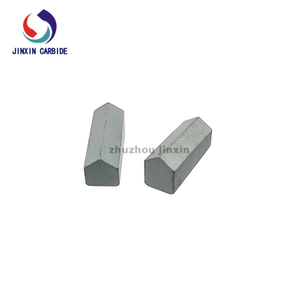

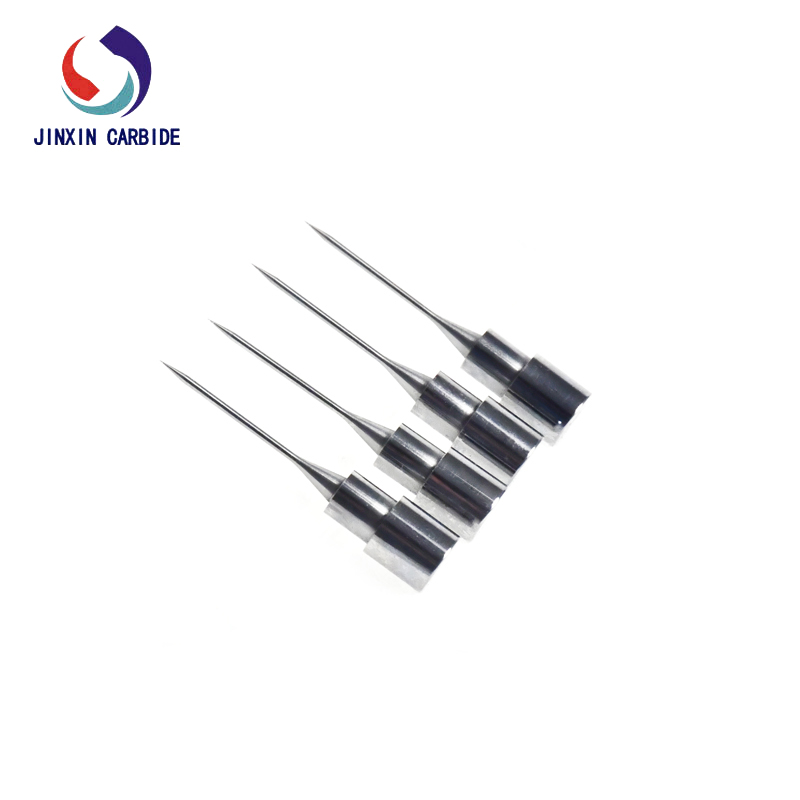

Tungsten Carbide punch pins description

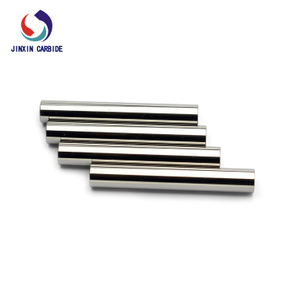

Tungsten carbide is a major component of cemented carbide materials. As hard phase of refractory metal, the tungsten steel is used with transition metal (Co, etc.) as the binder phase. The super-hard material prepared by powder metallurgy technology is cemented carbide. Cemented carbide has the advantages of high strength, high hardness, wear resistance,corrosion resistance, high temperature resistance and small coefficient of linear expansion.

It is one of the excellent tool materials, widely used in many industrial production and processing operations. Especially for the use of precision mold equipment, such as the tungsten carbide punch pin used in the AR8 anti-vibration rotor core stamping mold. Material performance is the basic use requirement, and long-lasting life is the efficiency guarantee for industrial mass production.

Tungsten Carbide punch Pins Application

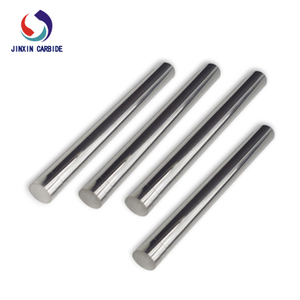

1. For PCB drills, drills, end mills & hole drilling tools

2. For reamers

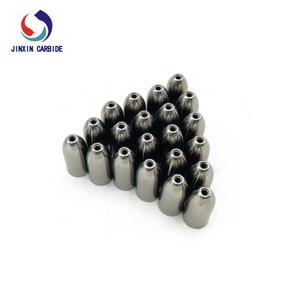

3. For mold punches

4. core pins

5. Metal working,Blanks rods for tungsten carbide burs,tungsten carbide milling cutters,tungsten carbide drills,tungsten carbide end mills,tungsten carbide reamers,tungsten carbide electrical drills,countersink, to machine HSS material,Alu ,steel,and stainless steel,etc.

6. Wood working,blanks and finished solid tungsten carbide rods for wood working stone pit industry and mining industry.

7.Stone working,blank and finished solid tungsten carbide rods for crusher machining of marble,granite,cobblestone,mountain stone,etc.

8. Scriber pens for marking glass and tiles,ect.

9. Other application,such as wear resistance parts of punching mold,measuring and cutting industry.

Tungsten Carbide punch Pins production

Jinxin can provide punching pins and sleeves used for precision mold parts, we can also produce tungsten steel inner and outer rotor pin, rotor forming pin, rotor metering pins, etc. according to the core stamping mold requirements of the customers. According to the actual operation requirements and customer's specific drawing as the precision tolerance standard, we provide non-standard forming of tungsten carbide.

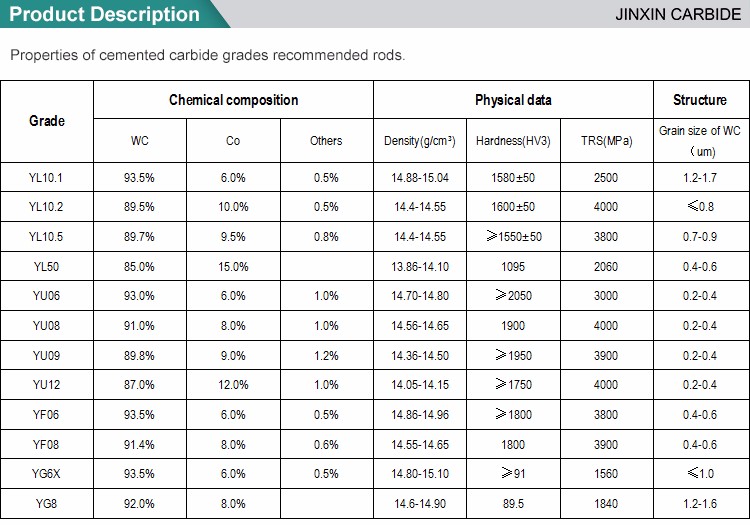

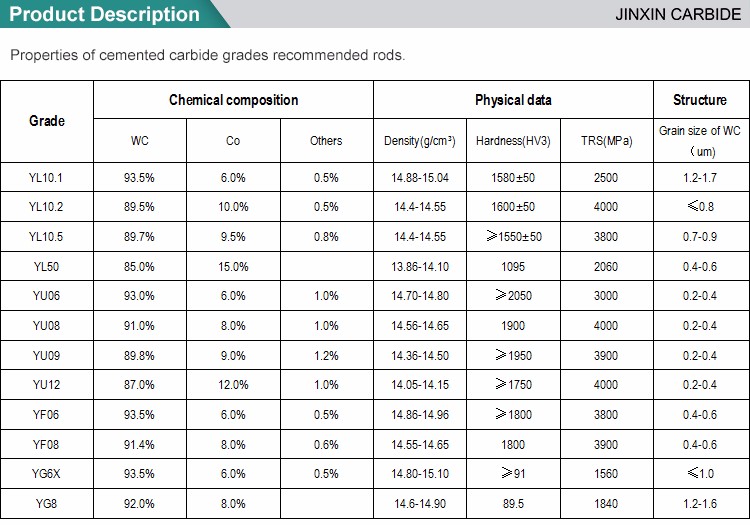

The physical parameters of conventional tungsten carbide non-standard forming pin production materials can be referred toas follows:

* Grain size (um): 0.8 ~ 2.0

* Cobalt content (Co%): 6 ~ 10

* Density (g/cm³): 14.45

* Hardness (HRA): 88 ~ 92

* Bending strength (Mpa): 3200 ~ 3800

* Young's modulus (Gpa): 570

* Compressive strength (Mpa): 4700

Tungsten carbide punch pins specification

Tungsten carbide punch pins photo and service

+86-18073319589

+86-18073319589