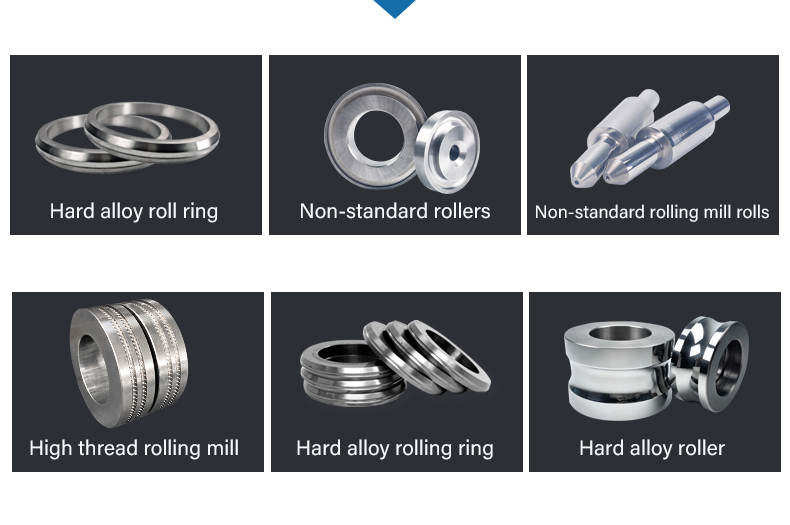

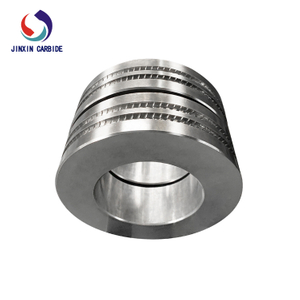

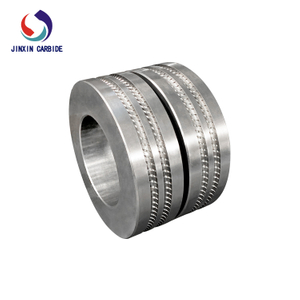

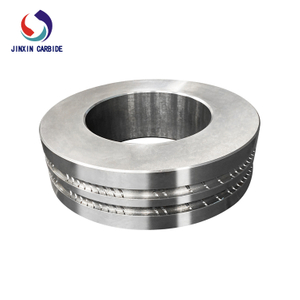

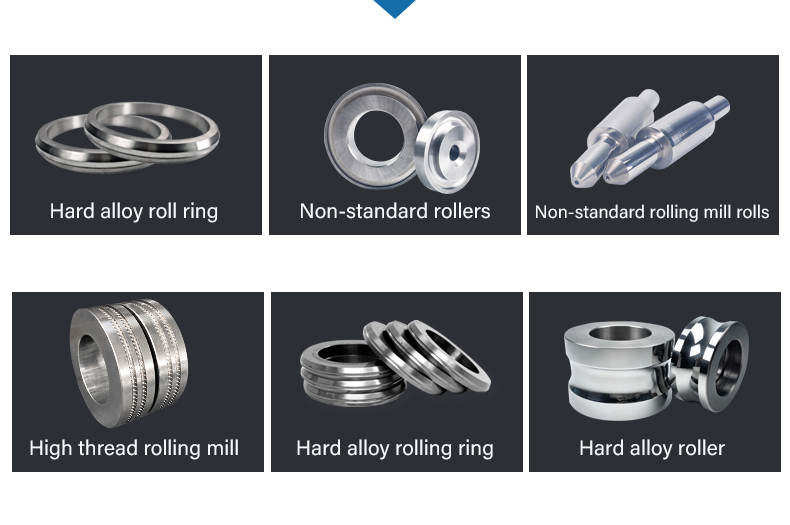

Tungsten Carbide Guide Wheel

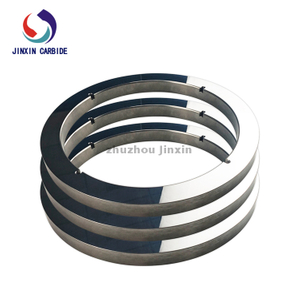

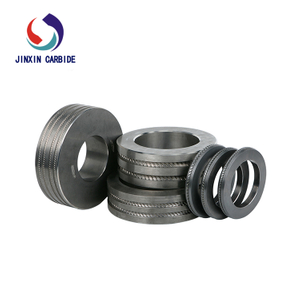

Tungsten carbide roller ring is made by tungsten carbide which could improve the mechanical characteristics of the cold rolled wire. They are used for removing any bends, irregularities, and mills left in the material that is being processed. Also could be used for wire straightening it could ensures that the final wire or rod will be consistent and free off defects.

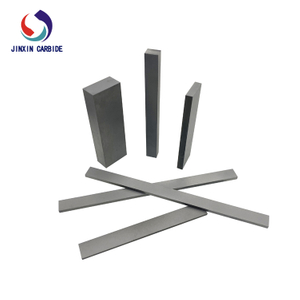

Carbide guide wheel Details

1.Tungsten carbide guide wheel adopt new forming technology, can produce a variety of complex shape of hard alloy products; Production can be organized according to the user's drawings.

2.the product deformation is small, precision is high;

3. the impact toughness is superior, not easy to drop, the number of shocks increased more than the previous year.

+86-18073319589

+86-18073319589