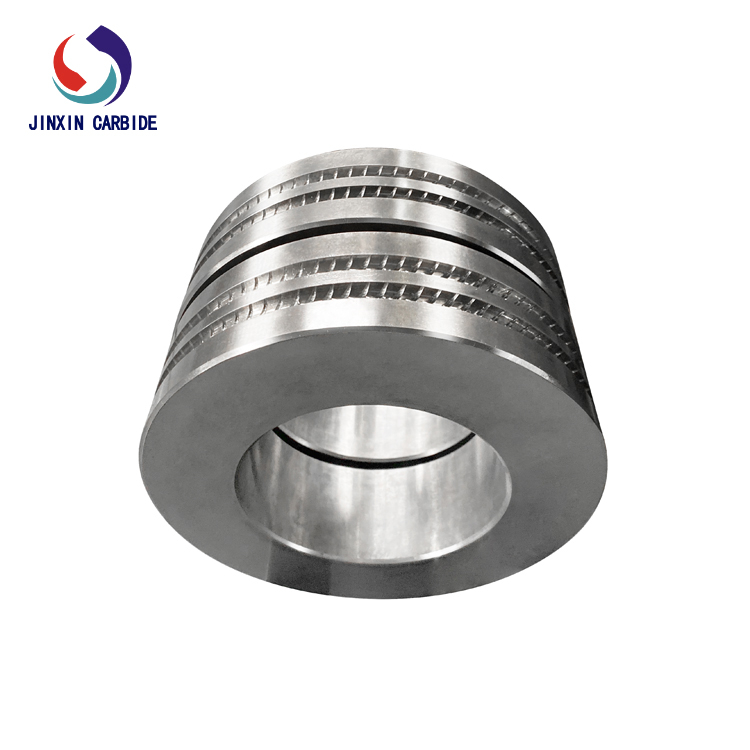

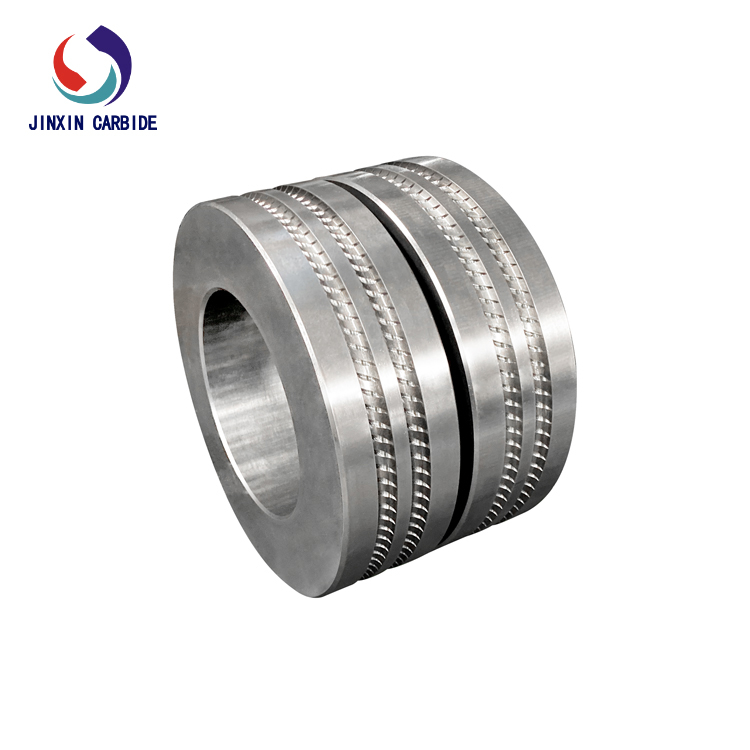

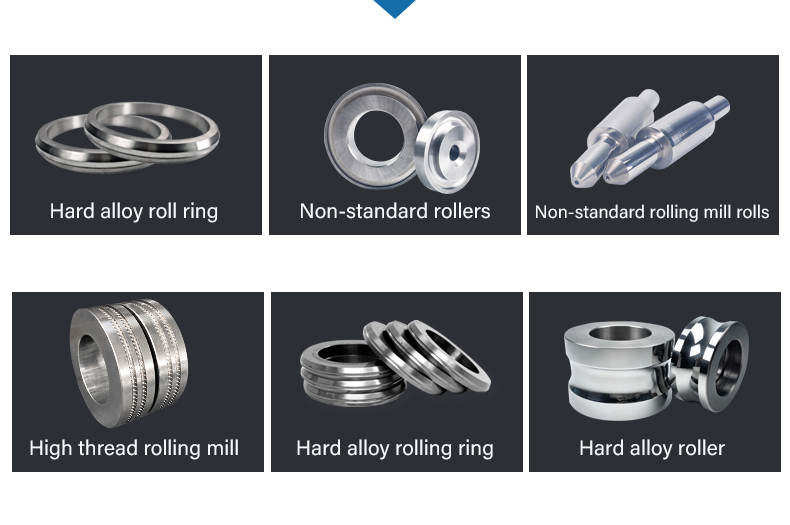

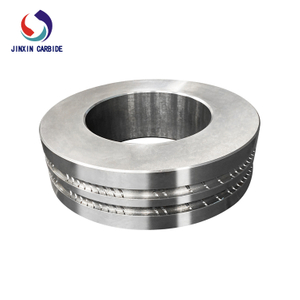

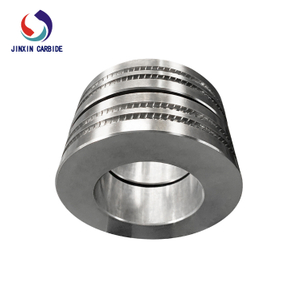

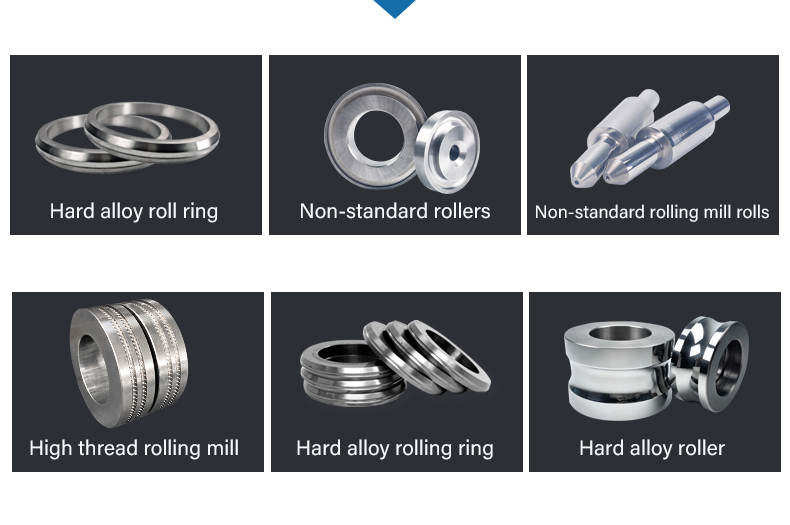

Product Overview

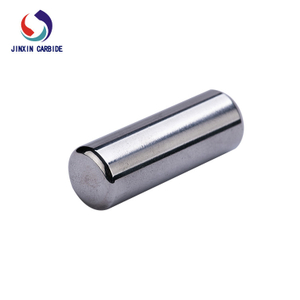

Jinxin Tungsten Carbide Roller Ring is a high-performance metallurgical tool made from premium tungsten carbide and cobalt materials. With exceptional hardness, high wear resistance, and superior toughness, it is ideal for applications where strength, durability, and long service life are essential.

The performance of Jinxin carbide rollers depends on the proportion of the metallic binder and the grain size of tungsten carbide particles. By adjusting these parameters, Jinxin produces various carbide grades tailored to meet different rolling requirements. Increasing the binder content or carbide particle size slightly reduces hardness but enhances toughness—ensuring the perfect balance between wear resistance and strength.

Features & Advantages

1. High Hardness & Strength: Tungsten carbide (WC) is nearly twice as strong as steel and similar to corundum in hardness.

2. Outstanding Wear Resistance: Ensures stable performance under high-speed and heavy-load conditions.

3. Extended Service Life: 10–20 times longer durability compared with traditional steel rollers.

4. Precision Manufacturing: Jinxin provides rollers in various sizes and custom designs to meet customer specifications.

5. Cost Efficiency: Reduces production costs while improving product quality and surface finish.

Applications

Jinxin cemented carbide roller rings are widely used in:

1. Stretch reducing mills for bars and rebar

2. Profile wire rolling

3. Flat and plain wire rolling

4. Construction and welding wire rolling

5. Wire straightening and guiding

They offer excellent performance for bars, thread steel, and common wire production, significantly improving surface quality, size accuracy, and rolling efficiency.

+86-18073319589

+86-18073319589