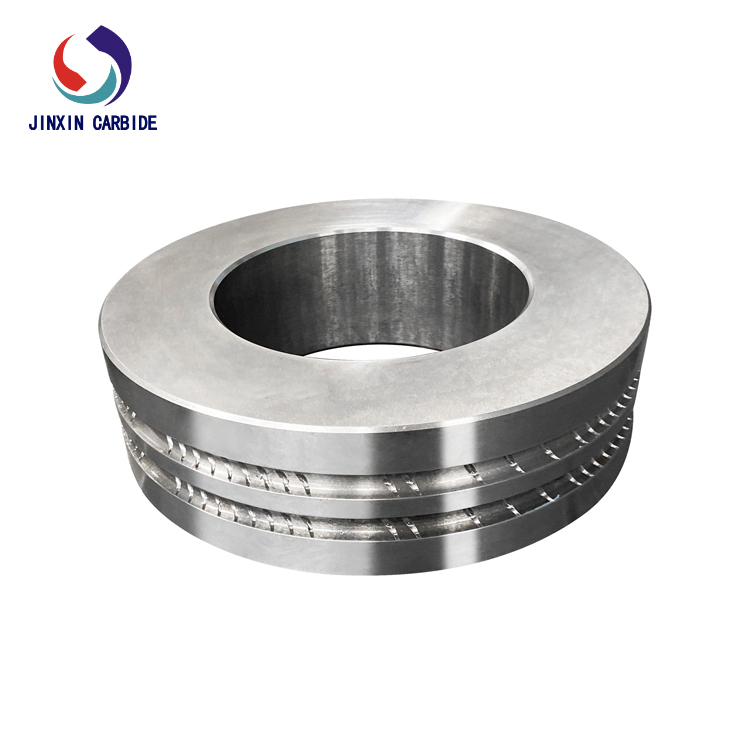

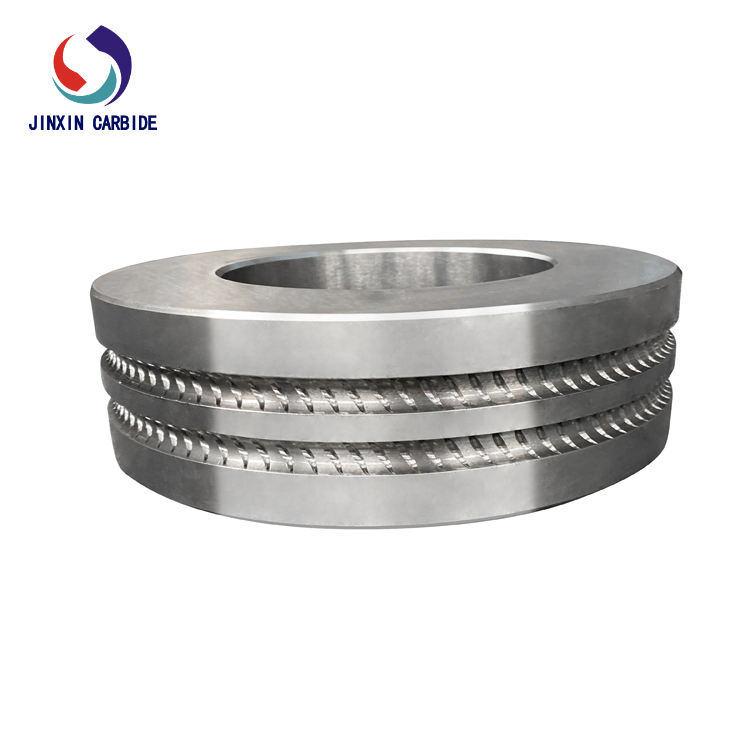

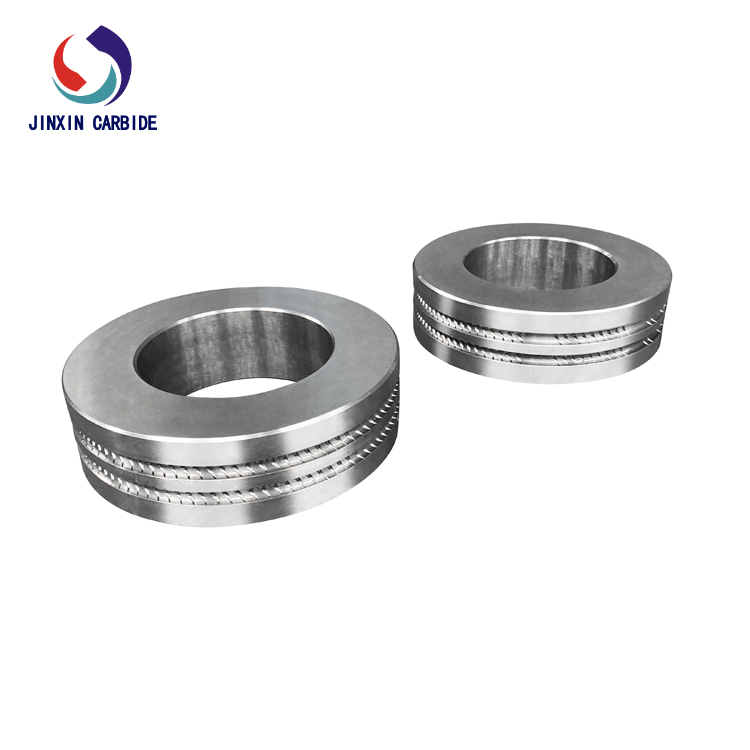

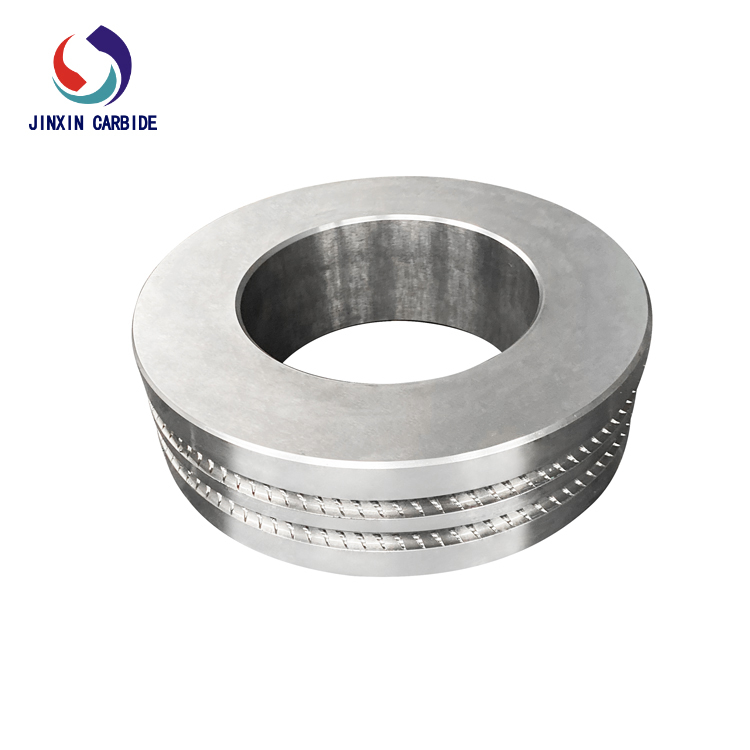

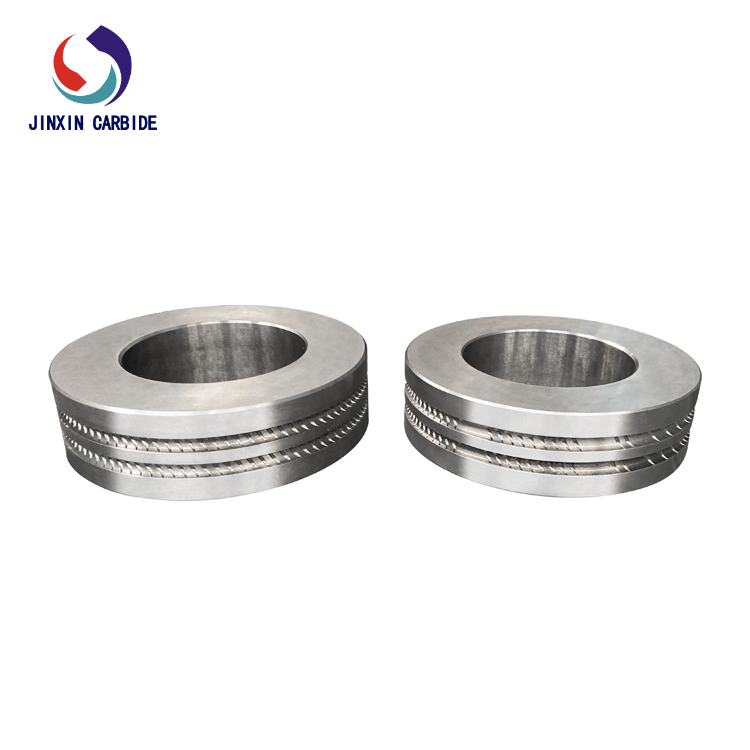

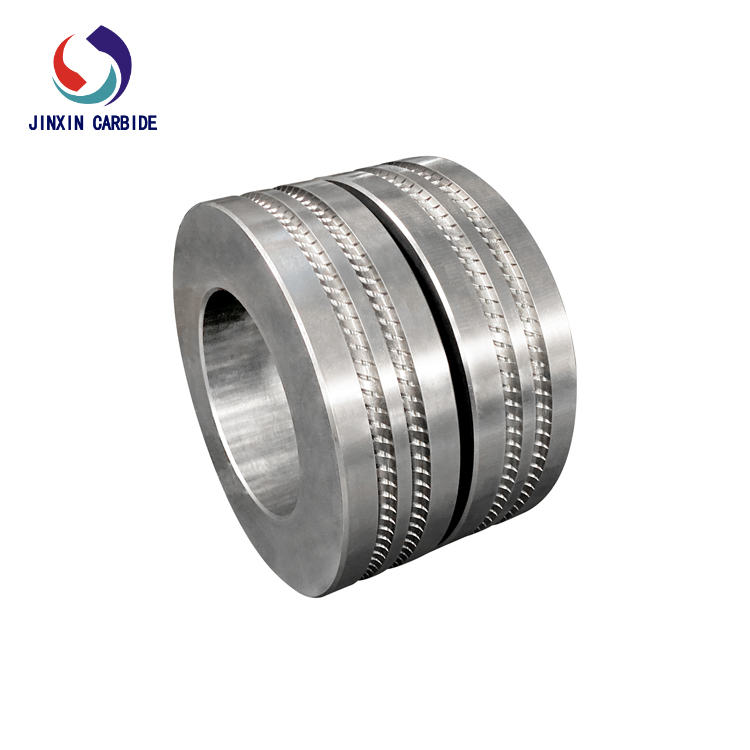

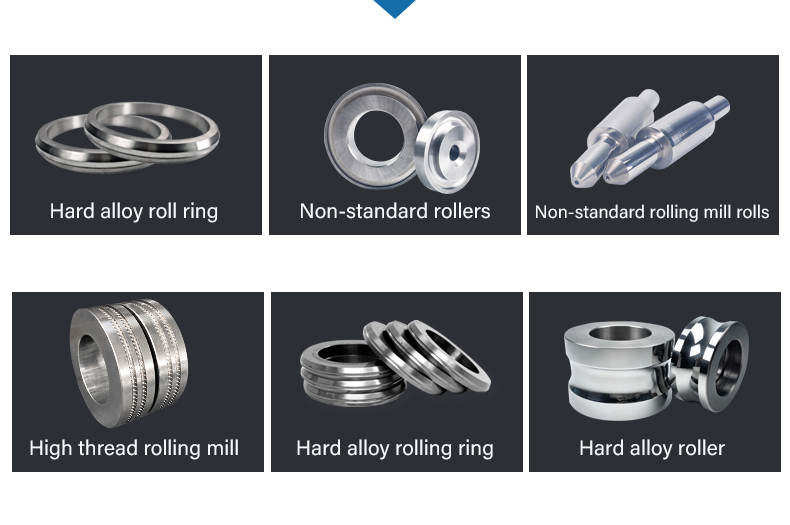

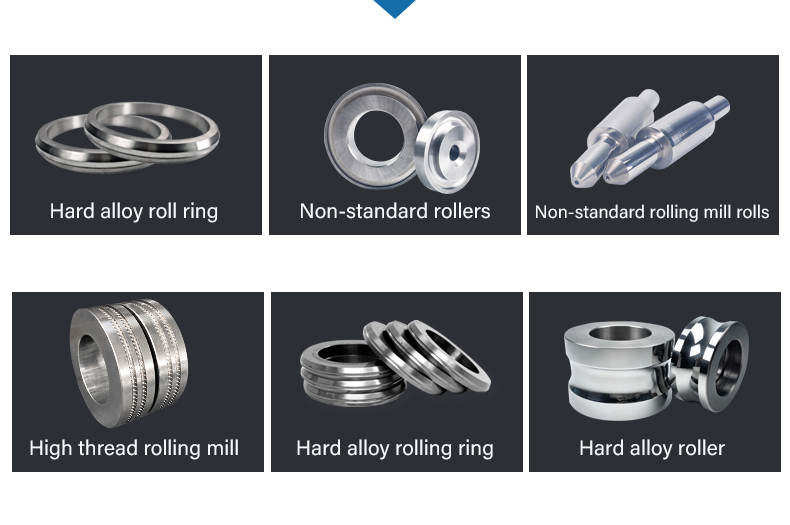

Jinxin Cemented Carbide Roll Rings

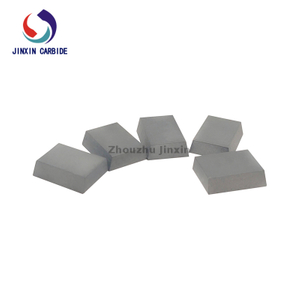

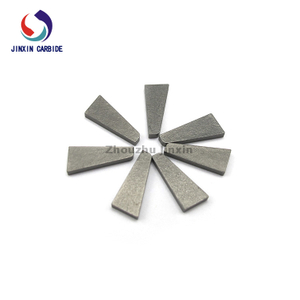

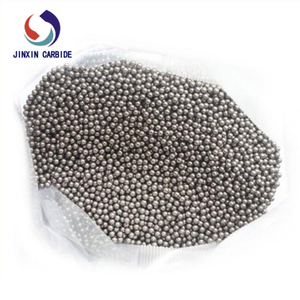

With high strength, excellent hardness, and superior wear resistance, Jinxin tungsten carbide roll rings (composed of WC, Co, Ni, and other rare metals) are specially developed for high-speed wire and bar rolling applications.With high strength, excellent hardness, and superior wear resistance, Jinxin tungsten carbide roll rings (composed of WC, Co, Ni, and other rare metals) are specially developed for high-speed wire and bar rolling applications.

Features & Advantages

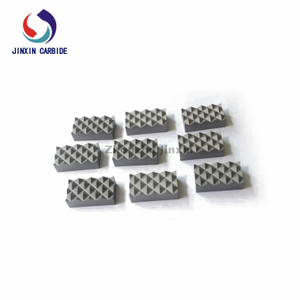

1. High Hardness & Strength: Tungsten carbide (WC) is nearly twice as strong as steel and similar to corundum in hardness.

2. Outstanding Wear Resistance: Ensures stable performance under high-speed and heavy-load conditions.

3. Extended Service Life: 10–20 times longer durability compared with traditional steel rollers.

4. Precision Manufacturing: Jinxin provides rollers in various sizes and custom designs to meet customer specifications.

5. Cost Efficiency: Reduces production costs while improving product quality and surface finish.

+86-18073319589

+86-18073319589