Tungsten Carbide is one of the hardest materials known to man. But what makes it so durable? Its composition and structure are key to its exceptional properties. In this post, we'll explore how the unique combination of Tungsten and Carbon creates a material that excels in high-stress environments. You'll learn how its atomic structure and grain size contribute to its remarkable hardness and wear resistance.

What is Tungsten Carbide Made Of?

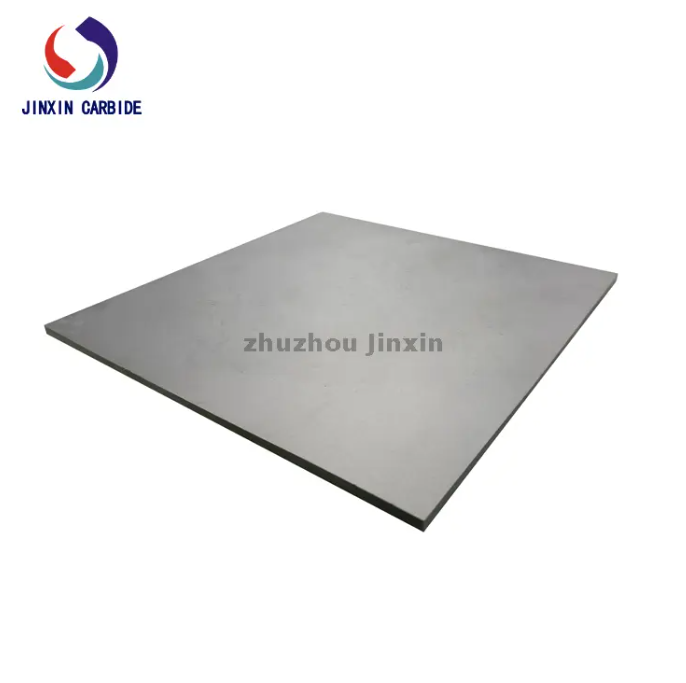

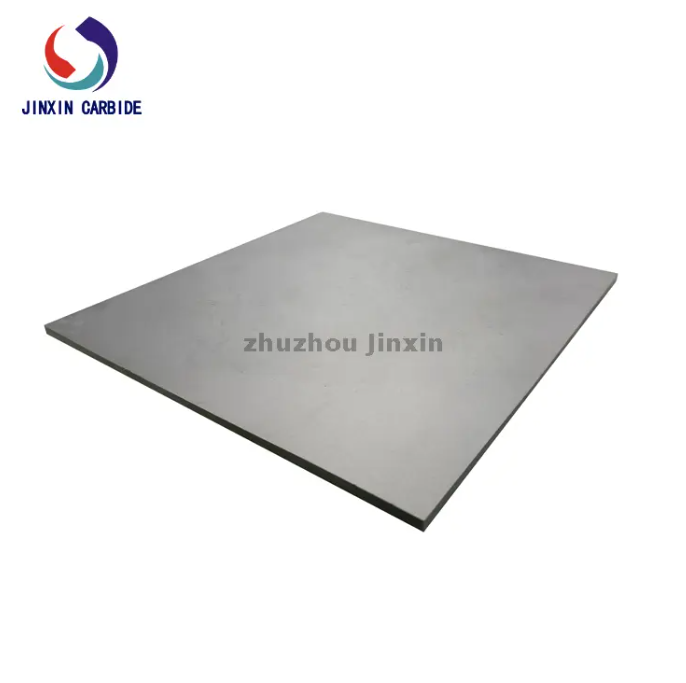

Tungsten Carbide (WC) is a material formed from the combination of two elements: Tungsten (W) and Carbon (C). The formula "WC" represents a 1:1 atomic ratio of Tungsten to Carbon. Despite its simplicity, this pairing creates a material known for its exceptional durability and strength.

Chemical Composition of Tungsten Carbide

Tungsten (W) is the dominant element in Tungsten Carbide because of its high atomic mass. Tungsten is one of the heaviest elements and contributes significantly to the material's incredible hardness. Carbon (C), though lighter, plays a crucial role in bonding with Tungsten, creating a carbide that can withstand extreme forces. The balance of these two elements results in a material that is both incredibly dense and resistant to wear.

The high atomic mass of Tungsten also influences the density and strength of Tungsten Carbide. This combination of Tungsten and Carbon in a 1:1 ratio is what gives Tungsten Carbide its characteristic properties, making it one of the hardest materials known to man.

Physical Properties of Tungsten Carbide

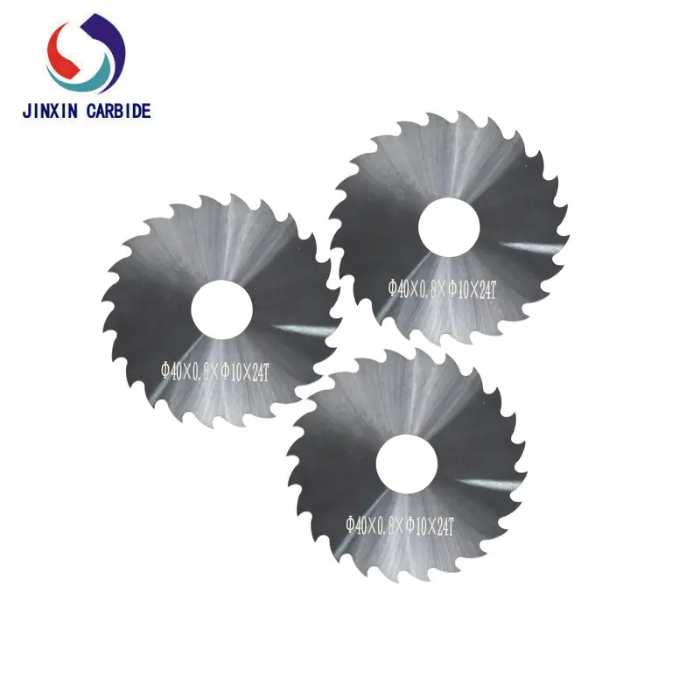

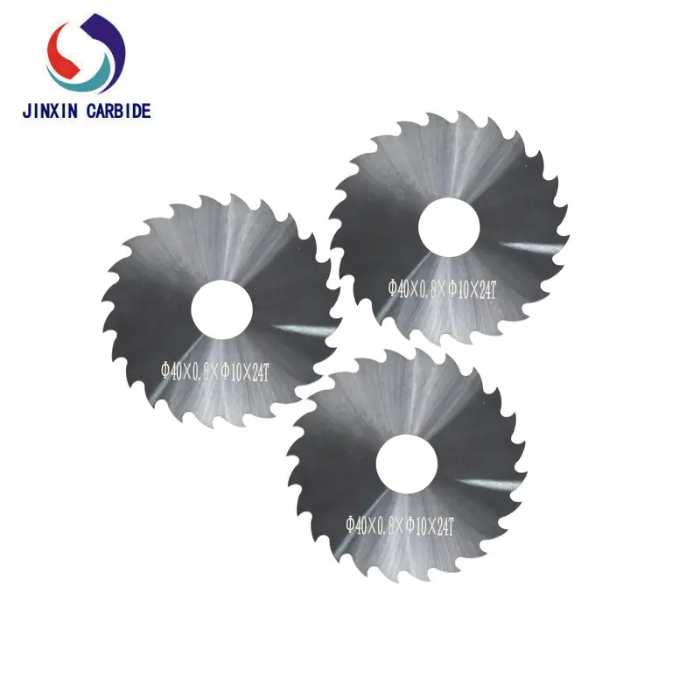

Tungsten Carbide's most notable physical property is its extreme hardness, second only to diamonds. This hardness makes it highly resistant to wear and ideal for use in cutting tools, drills, and industrial machinery. Whether it's machining metal or drilling through tough rock, Tungsten Carbide's hardness allows it to maintain a sharp edge even after extensive use.

In addition to its hardness, Tungsten Carbide also has an incredibly high melting point, around 5,200°F (2,870°C). This makes it suitable for high-temperature applications like aerospace, mining, and manufacturing.

Tungsten Carbide's toughness is another key factor in its usefulness. It can endure significant stress and impact without cracking or breaking, which is why it is commonly used in heavy-duty applications where other materials would fail. Its ability to resist damage from high pressure and harsh environments makes it an ideal choice for industrial tools and machinery exposed to extreme conditions.

How Does the Atomic Structure of Tungsten Carbide Affect Its Performance?

Tungsten Carbide's remarkable performance stems from its atomic structure. At room temperature, it adopts a hexagonal crystal structure (α-WC). In this structure, each Tungsten (W) atom is surrounded by six Carbon (C) atoms, forming a trigonal prism. This unique arrangement gives Tungsten Carbide its superior hardness and durability.

Crystal Structure

The hexagonal crystal structure of Tungsten Carbide is crucial for its impressive hardness. In this arrangement, the Tungsten and Carbon atoms are tightly bonded, making it extremely resistant to deformation under stress. When external force is applied to Tungsten Carbide, the atoms do not easily slide past each other. Instead, they hold their position, which helps the material retain its sharp edges and shape.

This crystal structure also allows Tungsten Carbide to maintain its strength and integrity even in extreme conditions, such as high temperatures or intense pressures. Unlike many other materials that might bend or break under stress, Tungsten Carbide remains rigid and durable, making it an ideal material for heavy-duty industrial applications.

Bonding and Lattice Characteristics

Tungsten-Carbon (W-C) bonds are particularly strong due to the nature of the covalent bonding between Tungsten and Carbon atoms. Unlike metallic bonds found in materials like steel, covalent bonds create stronger, more stable connections between atoms. This leads to an increase in hardness, wear resistance, and compressive strength, making Tungsten Carbide a top choice for applications requiring extreme durability.

The strength of these W-C bonds directly impacts the wear resistance of Tungsten Carbide. When exposed to abrasive conditions, the bonds resist breakage, preventing the material from wearing down. The hardness also allows Tungsten Carbide to maintain its sharpness longer than many other materials, which is why it's frequently used in cutting, drilling, and grinding tools.

When compared to steel, which relies on metallic bonds (weaker than covalent bonds), Tungsten Carbide stands out as the harder material. Steel, although strong, lacks the same level of durability in harsh environments. Tungsten Carbide's covalent bonds give it a substantial advantage, enabling it to outperform steel in applications where wear resistance and hardness are essential.

These unique bonding characteristics make Tungsten Carbide one of the most durable materials available, ensuring its use in industries such as mining, manufacturing, and aerospace, where it endures extreme conditions without degrading.

How Does the Grain Size of Tungsten Carbide Affect Its Properties?

The grain size of Tungsten Carbide is a critical factor in shaping its overall properties. Smaller or larger grains can significantly impact the material's hardness, toughness, and wear resistance. Understanding how grain size affects these characteristics is essential for choosing the right Tungsten Carbide for various applications.

Fine vs. Coarse Grains

Tungsten Carbide can be engineered with either fine or coarse grains, and each type offers distinct benefits.

Grain Size and Wear Resistance

The grain size also influences the material's wear resistance. A key point to remember is that there is a trade-off between hardness and wear resistance.

When you choose Tungsten Carbide for a specific task, you need to balance the need for hardness with the ability to resist wear. Smaller grains are great for fine, sharp work, while larger grains are more suitable for environments where durability under stress is crucial.

The Role of Binders in Cemented Tungsten Carbide

Cemented Carbide is a composite material made from hard Tungsten Carbide particles bonded together by a softer metal binder like Cobalt (Co) or Nickel (Ni). This combination of hard and soft components enhances the material’s overall performance by balancing high hardness with improved toughness and durability.

Why Are Binders Necessary?

Pure Tungsten Carbide, while incredibly hard, is also very brittle. This makes it difficult to use in practical applications where flexibility and resistance to impact are needed. Without binders, the material would be prone to cracking or shattering under stress. Binders like Cobalt or Nickel help address this issue by increasing the material's ductility (ability to deform without breaking) and impact resistance. This makes Tungsten Carbide more versatile and capable of withstanding the tough conditions found in industrial settings, such as mining or cutting.

Types of Binders

There are a few types of binders used to create Cemented Tungsten Carbide, and each offers different benefits:

Effect of Binder Content on Properties

The content of binder in Cemented Tungsten Carbide significantly influences its overall properties, especially in terms of hardness and toughness.

The amount of binder used can be adjusted to match the specific needs of the application, allowing for a fine balance between toughness, hardness, and wear resistance. For example, in industrial tools where high impact is expected, higher binder content is preferable. But for precision cutting tools, lower binder content might be chosen to keep the material harder and sharper.

Conclusion

Tungsten Carbide's unique atomic structure, grain size, and binder content contribute to its hardness and durability. These factors make it ideal for a variety of applications, from industrial tools to medical instruments. Choosing the right type of Tungsten Carbide based on specific needs is crucial to maximize performance and efficiency in various industries.

Jingxin has years of experience in production and sales of tungsten carbide tools. If you want to know more about tungsten carbide, feel free to contact us anytime with your inquiries.

FAQ

Q: Why is Tungsten Carbide Harder Than Steel?

A: Tungsten Carbide is harder than steel due to its strong Tungsten-Carbon (W-C) covalent bonds, which resist deformation. Unlike steel's metallic bonds, the W-C bonds in Tungsten Carbide provide superior hardness.

Q: Can Tungsten Carbide Rust?

A: Tungsten Carbide itself is corrosion-resistant. However, when bonded with Cobalt, it may oxidize in acidic environments. Nickel-bonded Tungsten Carbide offers better corrosion resistance.

Q: How is Tungsten Carbide Recycled?

A: Tungsten Carbide is recycled by crushing it into powder, oxidizing it to Tungsten Oxide (WO₃), and reducing it back to Tungsten. Cobalt is recovered through hydrometallurgy.

Q: What is the Difference Between Tungsten Carbide and Diamond?

A: Diamond is harder than Tungsten Carbide, but Tungsten Carbide performs better at high temperatures (above 600°C), making it more suitable for certain industrial applications.

Q: Is Tungsten Carbide Toxic?

A: Tungsten Carbide dust is hazardous if inhaled, but sintered parts are biologically inert. Nickel-bonded grades reduce cobalt toxicity concerns.

+86-18073319589

+86-18073319589