Ever wondered how some drill bits cut through the toughest materials effortlessly? The secret lies in tungsten carbide. Tungsten carbide bits are known for their durability and exceptional performance. They are used in industries like construction and manufacturing. In this post, we'll explore what tungsten carbide bits are, why they're essential, and their common applications.

Tungsten Carbide Bits Overview

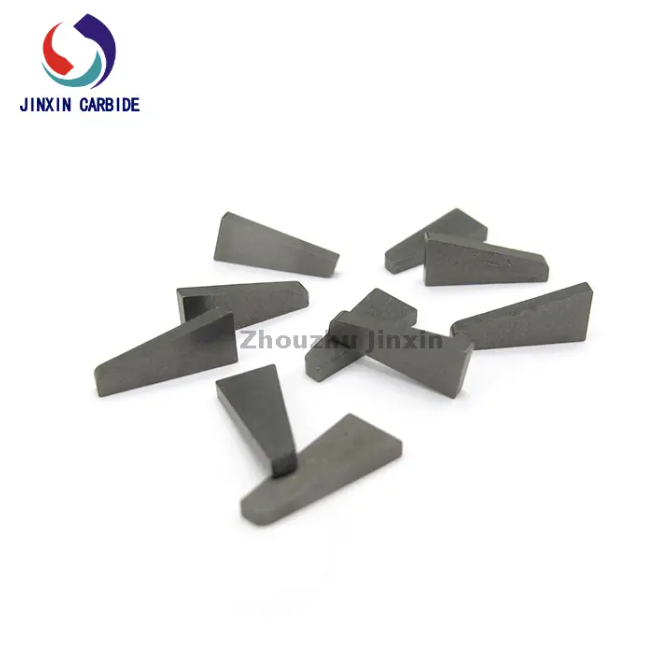

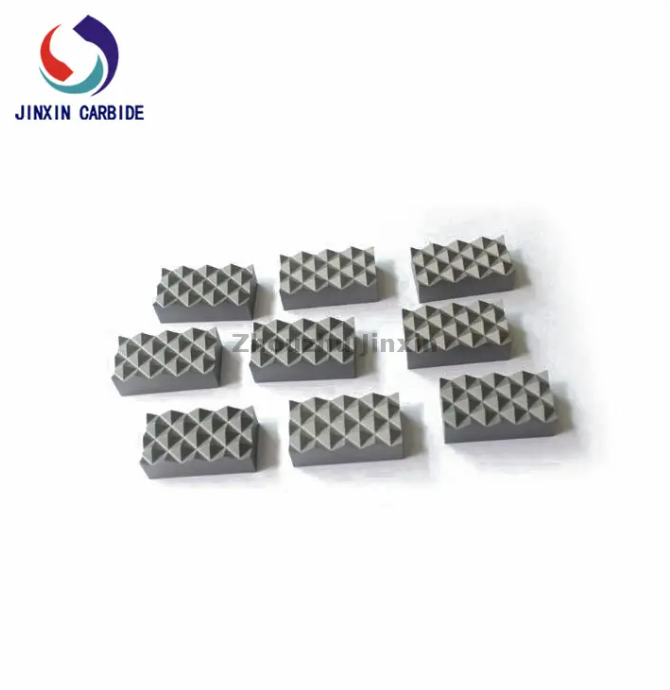

A tungsten carbide bit is a cutting tool known for its remarkable hardness and durability, made from a composite of tungsten and carbon. These bits are engineered to drill through some of the toughest materials, including metals, concrete, and masonry. Tungsten carbide bits come in two main types: carbide-tipped and full carbide. Carbide-tipped bits feature a steel body with a tungsten carbide cutting edge. They offer excellent toughness and are less likely to break under pressure. On the other hand, full carbide bits, made entirely of tungsten carbide, are extremely hard but can be more brittle when exposed to heavy stress.

Basic Structure of Tungsten Carbide Drill Bits

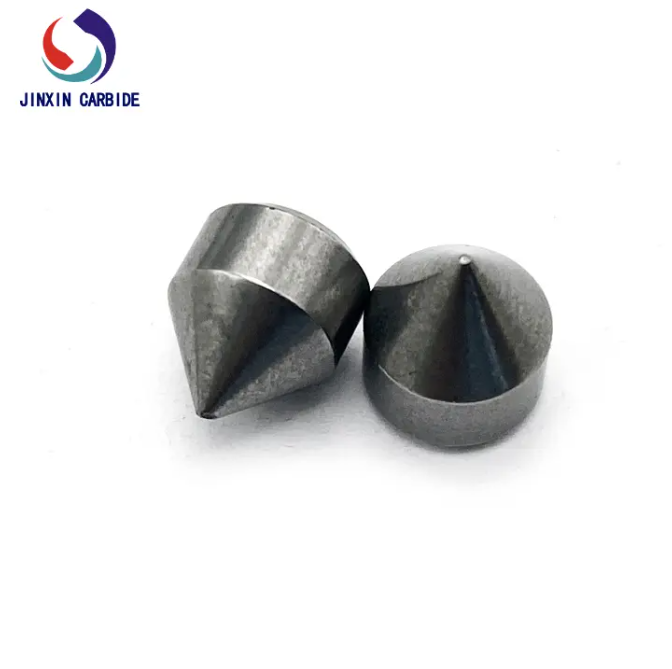

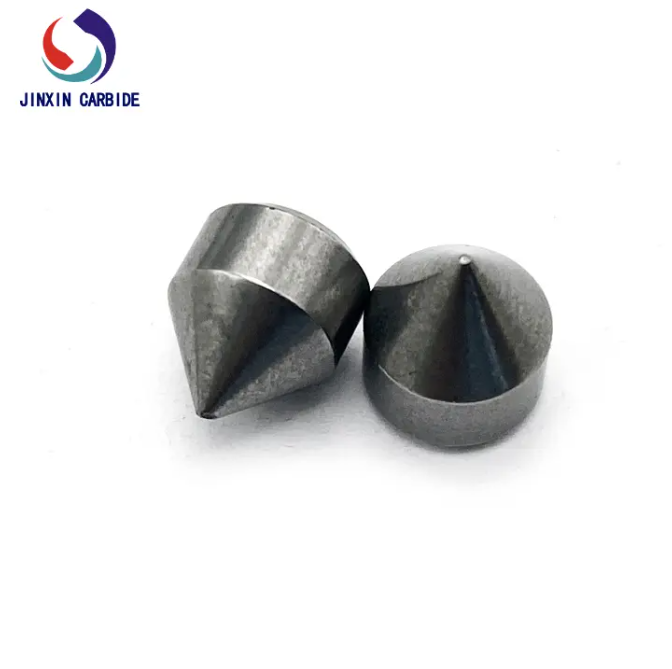

Tungsten carbide drill bits typically consist of two main parts: a steel shank and a carbide tip. The steel shank provides strength and flexibility, making the bit resistant to breaking during use. The carbide tip, which is the cutting edge, offers exceptional sharpness and longevity. It maintains its edge even after extended use, ensuring consistent performance when drilling through tough materials.

Why are Tungsten Carbide Bits Preferred?

Tungsten carbide bits are favored for their superior durability and longevity. They retain their sharpness much longer than other drill bits, reducing the need for frequent replacements and saving time and money. Additionally, these bits provide superior cutting performance. They cut through materials more efficiently, maintaining high drilling speeds without sacrificing precision. Tungsten carbide bits also stand out for their resistance to wear and heat. They can withstand extreme temperatures during high-speed drilling, ensuring that they don't wear out or lose their effectiveness even in demanding conditions. This combination of features makes tungsten carbide bits essential for industries requiring precision and reliability, such as construction and manufacturing.

Types of Tungsten Carbide Bits

Tungsten carbide bits come in various designs, each suited for specific tasks. These bits offer versatility, enabling users to handle different materials and projects efficiently. Below are some of the most common types:

Twist Drill Bits

Twist drill bits are the most commonly used type of carbide bit. Their spiral shape helps with cutting and removing debris as they drill. They are ideal for general-purpose drilling in materials like metal, wood, and plastics. Twist drill bits are particularly effective when working with softer metals, aluminum, and thin steel.

Masonry Bits

Masonry bits are designed for tough materials such as concrete, brick, and stone. These bits feature a carbide tip that withstands the abrasive nature of masonry materials. The bit's design allows it to handle high-impact drilling without losing its sharpness. Masonry bits are essential when drilling holes for anchors, pipes, or electrical fittings in concrete walls.

Core Bits

Core bits are used to extract cylindrical samples from materials like concrete, soil, or stone. These bits remove a core of the material rather than drilling through it completely. Core bits are essential for applications such as geological surveys, drilling through concrete for plumbing, or creating holes for installation of large pipes.

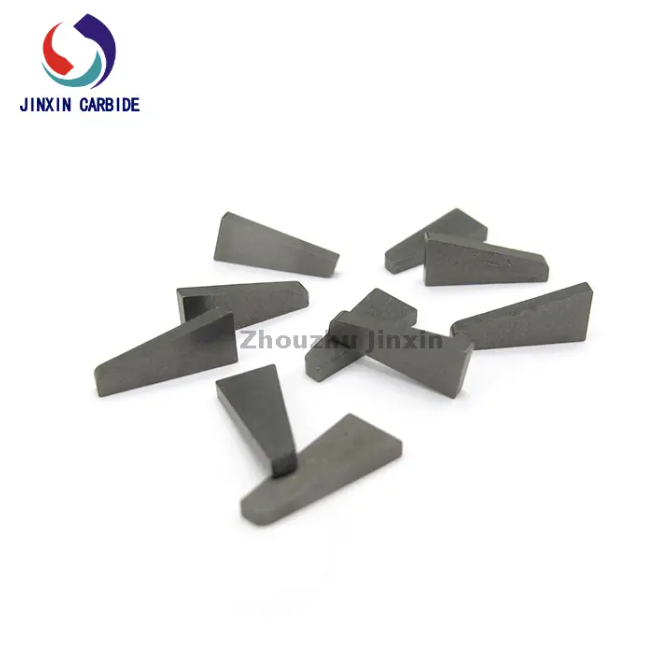

End Mills

End mills are primarily used in milling operations for shaping or cutting materials. They have a cutting edge on both the end and the side, making them more versatile than standard drill bits. End mills are common in manufacturing and metalworking, where precision cutting is needed for creating holes or intricate designs.

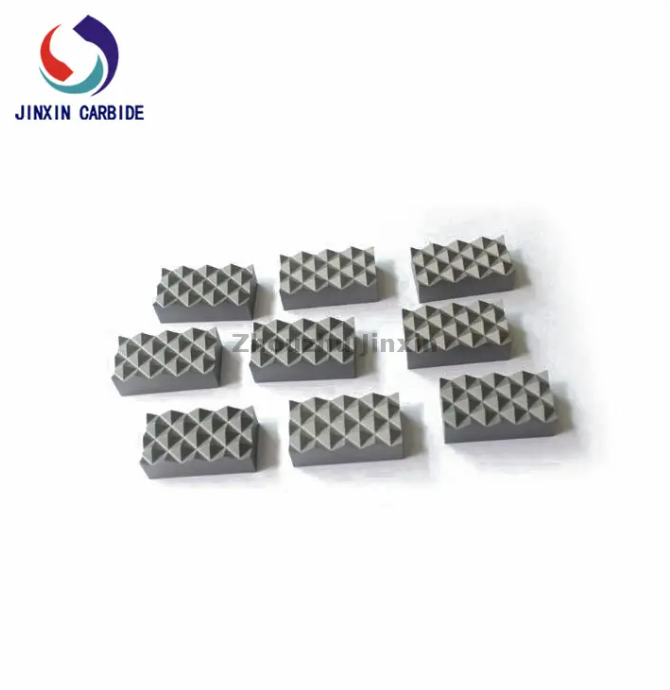

Threaded Bits

Threaded bits feature a threaded body that helps to grip the material as it drills. This type of bit is useful for creating holes where screws or bolts will later be inserted. Threaded bits are widely used in construction and mechanical work, particularly when working with materials like metal and concrete.

Applications for Each Type of Bit

● Twist drill bits are great for general drilling, ideal for wood, plastics, and softer metals.

● Masonry bits excel in drilling through concrete, brick, or stone, making them perfect for construction projects.

● Core bits are used when material samples need to be extracted, particularly useful for geological or construction site surveys.

● End mills are ideal for precise cuts and milling in materials like steel, aluminum, and other metals.

● Threaded bits are used when threaded holes need to be drilled for screws, bolts, or anchors.

Each type of tungsten carbide bit is designed for specific tasks, ensuring efficiency and precision when working with materials like concrete, metal, wood, and more.

Benefits of Using Tungsten Carbide Bits

Extended Tool Life

One of the most notable benefits of tungsten carbide bits is their extended tool life. Thanks to their superior wear resistance, these bits last far longer than traditional drill bits. The hardness of tungsten carbide means it can withstand repeated use without quickly dulling or breaking. As a result, the frequency of replacements is reduced, which translates to long-term cost savings. In industries that require frequent drilling, such as construction and manufacturing, investing in carbide bits can make a significant difference in reducing downtime and operational costs.

Precision Cutting

Tungsten carbide bits are engineered for precision cutting. In fields like metalworking, automotive, and construction, having clean, accurate cuts is essential. Carbide bits maintain their sharpness longer, ensuring that cuts remain precise even under heavy usage. Their ability to drill through tough materials without compromising on accuracy makes them a favorite in industries where exact measurements are crucial. Whether you're working with metal, masonry, or wood, tungsten carbide bits deliver consistent, high-quality results.

Versatility and Efficiency

Tungsten carbide bits are highly versatile and efficient. These bits can handle a wide variety of materials, including metals like steel and aluminum, masonry like concrete and brick, and even wood. This versatility means you can rely on a single type of bit for different tasks, reducing the need for multiple tools. Furthermore, their durability leads to faster drilling speeds and reduced downtime. Since carbide bits last longer and maintain sharpness, you won’t have to spend as much time replacing or sharpening them. This improves overall efficiency in any project, helping to get the job done faster while maintaining a high level of performance.

How Tungsten Carbide Bits Compare to Other Drill Bits

Tungsten Carbide vs. High-Speed Steel (HSS) Bits

Tungsten carbide bits are much harder and more durable than high-speed steel (HSS) bits. While HSS bits are great for softer materials and general-purpose drilling, they don't hold up as well when used on tough materials like steel or masonry. Tungsten carbide bits have superior strength and cutting speed, which means they can handle tougher jobs without dulling. HSS bits tend to wear out faster and need to be replaced more often, while carbide bits last much longer, making them more cost-effective for heavy-duty projects.

● When to choose carbide over HSS: Use carbide bits for harder materials, higher temperatures, and longer-term projects that require precision. HSS bits are suitable for lighter tasks and softer materials.

Tungsten Carbide vs. Cobalt Bits

Cobalt bits are made from a steel alloy with a small amount of cobalt, offering greater durability than standard HSS bits. While cobalt bits are better than HSS for drilling through tough metals, tungsten carbide still outperforms them in terms of hardness and cutting speed. Cobalt bits have better heat resistance than HSS, but they still can't match carbide's extreme wear and heat resistance.

● Similarities and differences: Both are tough, but carbide bits last longer and maintain their sharpness better. Cobalt is often preferred for drilling through hard metals like stainless steel, but carbide is better for high-speed, heavy-duty applications.

● Best use cases: Choose cobalt bits for heavy metal drilling, especially when working with high-strength steel. Go for tungsten carbide bits when precision, longevity, and versatility are key factors, especially for abrasive materials like concrete.

Tungsten Carbide vs. Titanium Bits

Titanium bits are made from steel coated with titanium, which increases their strength and reduces friction. However, tungsten carbide bits are significantly harder and more durable, especially when it comes to drilling through tough materials. Heat resistance is another major difference; while titanium bits handle heat better than HSS and cobalt, carbide bits still perform better in high-temperature conditions due to their superior strength.

● Hardness and durability comparison: Tungsten carbide bits are harder and last longer than titanium-coated bits. While titanium bits are good for general tasks, carbide bits are ideal for demanding applications where toughness and durability are critical.

● When to use: Use titanium bits for lighter jobs, especially on soft metals and wood. Tungsten carbide is the best choice for high-precision drilling in tough materials or for long-lasting performance.

Applications of Tungsten Carbide Bits in Various Industries

Tungsten Carbide Bits in Construction

In construction, tungsten carbide bits are essential for drilling through tough materials like concrete, masonry, and stone. Their extreme hardness allows them to handle the abrasive nature of these materials without losing sharpness. They are commonly used for drilling holes for fixtures, conduits, and anchor bolts in concrete walls or floors. Whether installing electrical systems or setting up plumbing, carbide bits ensure precision and efficiency in demanding construction projects.

Tungsten Carbide Bits in Manufacturing

Tungsten carbide bits are also widely used in machining, milling, and shaping tough materials in the manufacturing sector. These bits are perfect for precision tasks, such as cutting and drilling parts made from metals like steel, aluminum, and titanium. The high durability of carbide bits ensures that they remain sharp and effective throughout the entire process, enabling manufacturers to create high-precision parts that meet strict tolerances. Their ability to handle high-speed operations makes them indispensable for continuous, high-volume production.

Tungsten Carbide Bits in Mining and Oil & Gas

In industries like mining and oil & gas, tungsten carbide bits are crucial for drilling through hard geological formations. These bits can penetrate rock, shale, and other dense materials, making them the go-to choice for drilling operations in tough environmental conditions. Their ability to withstand high pressures and temperatures ensures that they perform reliably in deep-earth drilling, whether for mining valuable minerals or extracting oil and gas. The durability and heat resistance of carbide bits help reduce downtime, leading to more efficient and cost-effective operations.

Tungsten Carbide Bits in the Automotive Industry

The automotive industry relies on tungsten carbide bits for precision drilling in engine components, transmission parts, and other essential automotive parts. These bits are used for creating accurate holes in metals like steel and aluminum, which are commonly found in vehicle components. Carbide bits are particularly effective for high-precision work, where small tolerances are critical for performance and safety. Whether it's for engine assembly or other delicate parts, tungsten carbide bits ensure the high level of accuracy needed in automotive manufacturing.

Conclusion

Tungsten carbide bits are essential tools known for their durability, precision, and versatility. They last longer than other bits, offering significant cost savings over time. These bits excel in high-performance environments, making them ideal for demanding tasks in industries like construction, manufacturing, and mining. Investing in high-quality tungsten carbide bits ensures enhanced performance and efficiency, saving time and money on replacements and downtime. Welcome to Jingxin Consulting Products!

FAQ

Q: What are Tungsten Carbide Drill Bits Made Of?

A: Tungsten carbide drill bits are made from a combination of tungsten and carbon. This material is incredibly hard, making the bits highly durable. Many bits also have a steel body, with the carbide material forming the cutting edge for superior strength and wear resistance.

Q: Are Tungsten Carbide Bits Expensive?

A: Tungsten carbide bits are generally more expensive upfront compared to other types. However, their durability and longer lifespan make them cost-effective in the long run. They reduce the frequency of replacements, saving money over time.

Q: Can Tungsten Carbide Drill Bits Be Recycled?

A: Yes, tungsten carbide bits can be recycled. The process involves reclaiming the carbide material from worn-out bits, which can then be reused in new products. This helps reduce waste and conserve resources.

Q: Can Tungsten Carbide Bits be Used for Woodworking?

A: Tungsten carbide bits can be used for woodworking, but they are typically reserved for tougher jobs. While they can cut through hardwood, their primary strength lies in working with tougher materials like metal and masonry. They may not be ideal for routine woodwork due to their high hardness, which can cause splintering in some woods.

+86-18073319589

+86-18073319589