Tungsten carbide is one of the hardest materials known to man, essential for many industries. From cutting tools to mining equipment, its applications are vast. Understanding its properties is crucial for professionals in materials science, manufacturing, and tool-making. In this article, we'll explore what tungsten carbide is, its uses, and why it's so important.

Understanding Tungsten Carbide

What is Tungsten Carbide?

Tungsten carbide is an incredibly strong, dense material composed of tungsten and carbon atoms. Its chemical formula is WC, which reflects the perfect balance between tungsten's strength and carbon's hardness. This combination results in a material that is far harder than most metals, making it ideal for applications where durability and resistance to wear are essential.

Basic Properties

Tungsten carbide has several key properties that make it stand out:

● High hardness: Tungsten carbide ranks second only to diamonds on the Mohs scale of hardness, making it highly resistant to scratching and abrasion.

● Exceptional strength: It can endure immense pressure without fracturing or bending, which is why it's used in high-stress applications.

● Wear resistance: The material holds its form and sharpness even when exposed to harsh environments or extreme temperatures, ensuring a longer lifespan for tools and components made from it.

What Makes Tungsten Carbide Unique?

Tungsten carbide's unique characteristics give it an edge over other materials in many industries. The combination of extreme hardness, density, and resistance to wear allows it to perform in conditions where other metals might fail.

Comparison to Other Metals

When compared to materials like steel or titanium, tungsten carbide stands out for several reasons:

● Hardness: While steel can be hardened, it can't match the wear resistance of tungsten carbide. This makes tungsten carbide a top choice for cutting tools and industrial applications.

● Density: Tungsten carbide is much denser than steel or titanium. This property allows it to withstand higher forces without losing its integrity, which is why it's often used in mining and drilling equipment.

Its Hardness

Tungsten carbide's extraordinary hardness is a defining feature. Ranked just below diamond on the Mohs scale, it's ideal for high-precision tools like drill bits, cutting tools, and wear-resistant parts. This hardness helps tungsten carbide maintain sharp edges and precise shapes, even under extreme conditions. It's one of the main reasons why tungsten carbide is preferred in industries that require longevity and reliability, such as aerospace, mining, and manufacturing.

How Tungsten Carbide is Made

What is the Process of Manufacturing Tungsten Carbide?

Tungsten carbide is made through a series of carefully controlled steps in the Powder Metallurgy process. This technique involves mixing tungsten carbide powder with a binder, typically cobalt, to create a dense, durable material. The process is highly specialized to ensure the final product has the right balance of hardness, toughness, and wear resistance.

Key Steps in the Manufacturing Process:

1. Mixing: Tungsten carbide powder is combined with cobalt or other metal binders to create a uniform mixture.

2. Ball Milling: The mixture is placed in ball mills, where the fine grinding ensures a consistent blend. This process is crucial to achieving the right material properties.

3. Pressing: After milling, the powder is pressed into molds to form a rough shape of the final product. This is done using hydraulic or isostatic presses, which compact the powder into a dense form.

4. Sintering: The compacted powder is heated in a furnace at very high temperatures, bonding the particles together to form a solid piece.

How Does Sintering Work in Tungsten Carbide Production?

Sintering is one of the most crucial steps in the production of tungsten carbide. After the powder is pressed into shape, it is heated in a vacuum furnace at temperatures between 1300°C and 1600°C. This process helps the material bond and solidify.

● Purpose of Sintering: The heat causes the tungsten carbide particles to fuse together, transforming the material into a hard, durable composite.

● Fusing of Particles: During sintering, the particles bond tightly, increasing the density and strength of the material. The heat also causes the binder (usually cobalt) to melt, helping to bond the tungsten carbide particles more effectively.

The sintering process is carefully controlled to ensure the final product achieves the right density, hardness, and other important properties, like resistance to wear and high temperatures.

What is Green Machining and Why is it Important?

Green Machining is a process used to shape tungsten carbide before it undergoes sintering. At this stage, the material is still in a "green" state, meaning it is not yet fully hardened. The material is relatively soft and can be machined using conventional metalworking tools.

● Importance of Green Machining: This step is crucial because it allows for precise shaping of the material before it becomes too hard during sintering. It ensures that the final product will have the desired dimensions and can fit into the intended application.

● Careful Handling: While machining, it's important to control fine powder particles that can be harmful. Special extraction methods are used to remove these particles and prevent contamination of the material. Green machining also ensures that the tungsten carbide maintains its integrity and performance after sintering.

Properties of Tungsten Carbide

What are the Physical and Chemical Properties of Tungsten Carbide?

Tungsten carbide stands out due to its remarkable physical and chemical properties, which make it highly valuable across various industries:

● Hardness: Tungsten carbide is extremely hard, ranking just below diamond on the Mohs scale. This makes it resistant to scratching and wear, ensuring longevity in high-abrasion applications.

● Density: Tungsten carbide is significantly denser than most other metals, such as steel and titanium. This density gives it superior strength and resistance to wear.

● Toughness: Despite its hardness, tungsten carbide is tough and resistant to breaking or cracking, which allows it to endure under high-pressure and high-stress conditions.

Thermal Expansion and Resistance to High Temperatures

Tungsten carbide also excels when it comes to thermal stability:

● Low Thermal Expansion: It has a low thermal expansion coefficient, meaning it doesn't expand or contract much when exposed to temperature changes. This property helps maintain its shape and integrity in environments with fluctuating temperatures.

● High Resistance to Heat: Tungsten carbide can withstand extreme temperatures, with a melting point of 3,422°C. This makes it highly effective in industries that deal with high-temperature applications, such as aerospace, manufacturing, and machining.

Why is Tungsten Carbide So Durable?

Tungsten carbide's incredible durability comes from a combination of its physical and chemical properties:

● High Melting Point: Its exceptionally high melting point (3,422°C) means it can withstand intense heat without deforming. This property is crucial for materials exposed to high temperatures during use, such as cutting tools or engine components.

● Corrosion Resistance: Tungsten carbide is highly resistant to corrosion, even in harsh environments. Whether exposed to acids, alkalis, or other corrosive materials, tungsten carbide retains its strength and performance, making it ideal for use in industries like mining, oil drilling, and metalworking.

Comparing Tungsten Carbide to Other Materials

When comparing tungsten carbide to materials like steel, titanium, and high-speed steel (HSS), its unique advantages become clear:

● Steel: While steel can be hardened, tungsten carbide's hardness far exceeds that of steel, giving it superior wear resistance and making it ideal for applications where tools are exposed to heavy friction and abrasion.

● Titanium: Titanium is known for its strength and lightweight properties, but tungsten carbide is denser and more wear-resistant. This makes tungsten carbide a better choice for high-stress applications where durability and wear resistance are critical.

● High-Speed Steel (HSS): Although HSS is widely used for cutting tools, tungsten carbide has a clear edge. It is harder, more resistant to wear, and can withstand higher temperatures, making it more durable and effective for precision cutting tasks.

Applications of Tungsten Carbide

What are the Primary Uses of Tungsten Carbide?

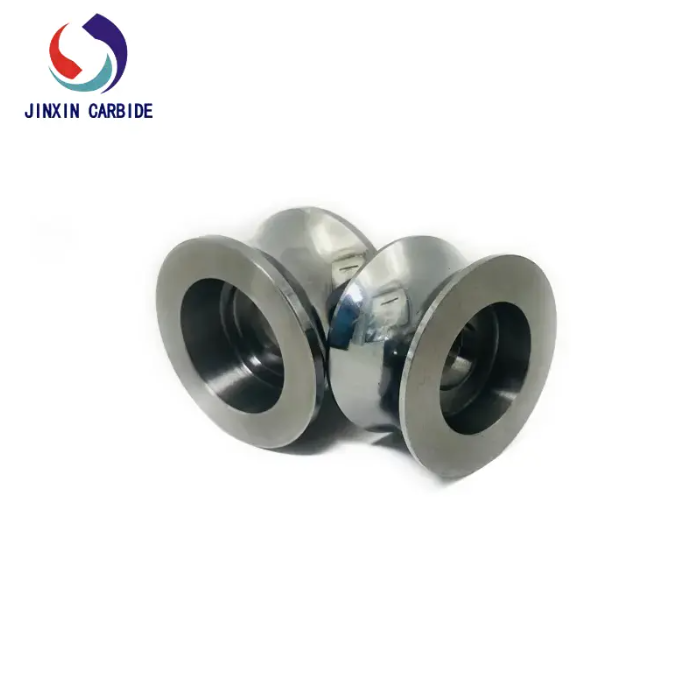

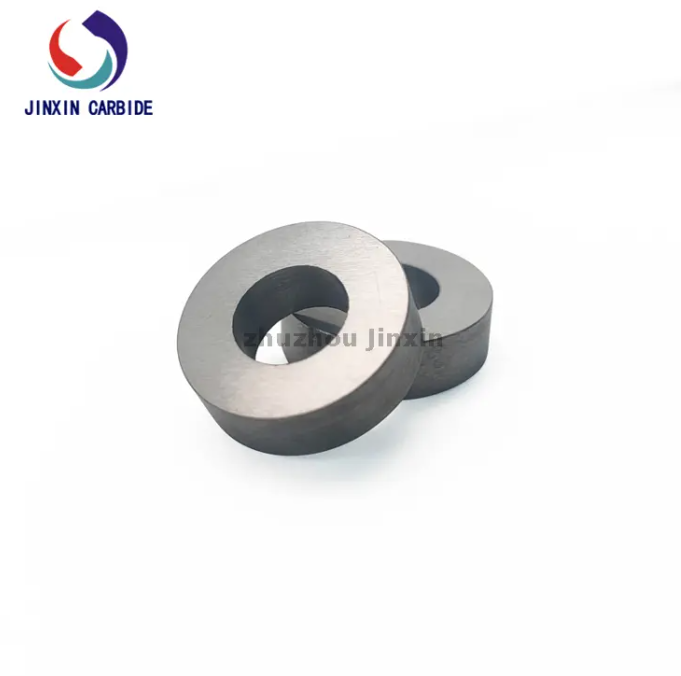

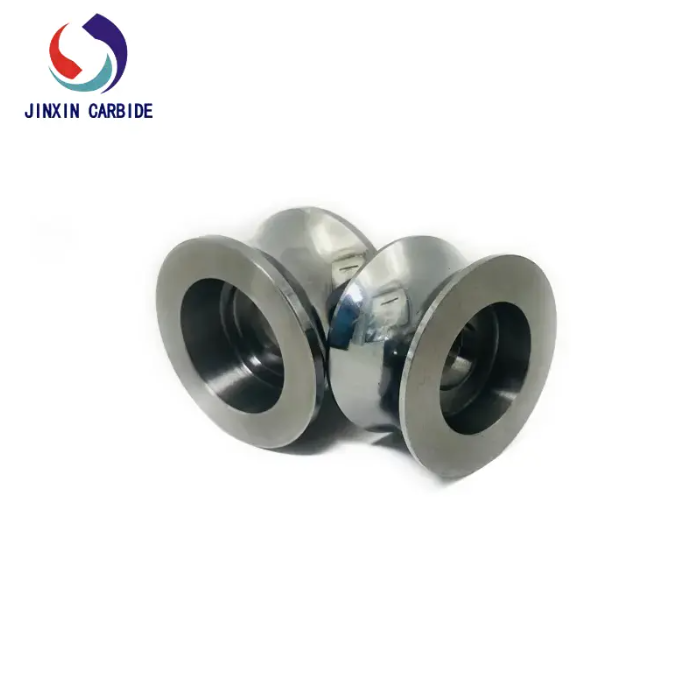

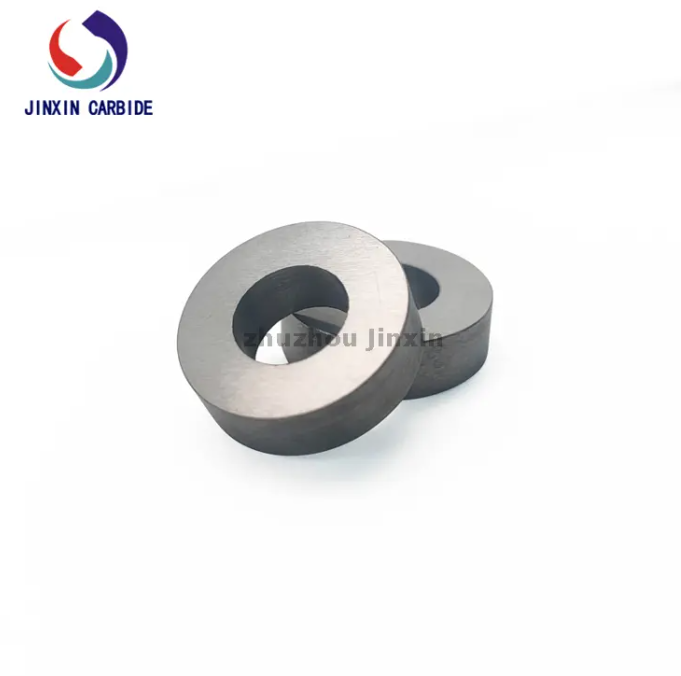

Tungsten carbide is widely used across various industries due to its hardness, durability, and resistance to wear. Some of its most common industrial uses include:

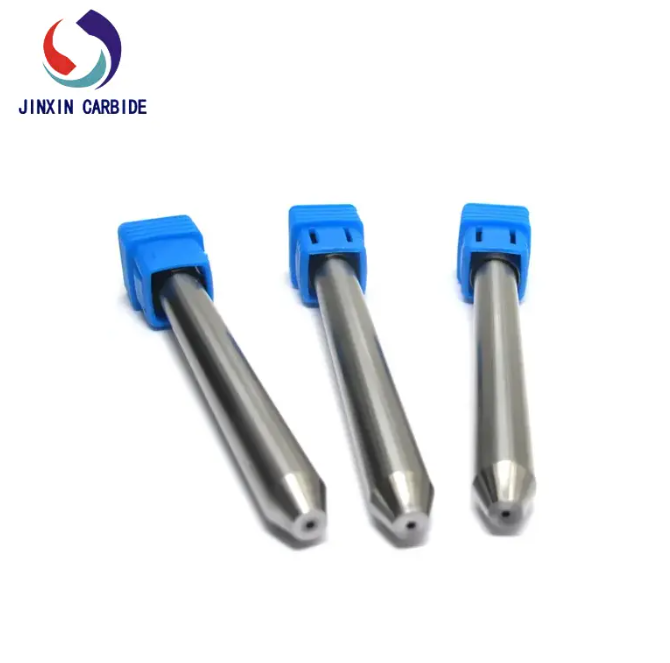

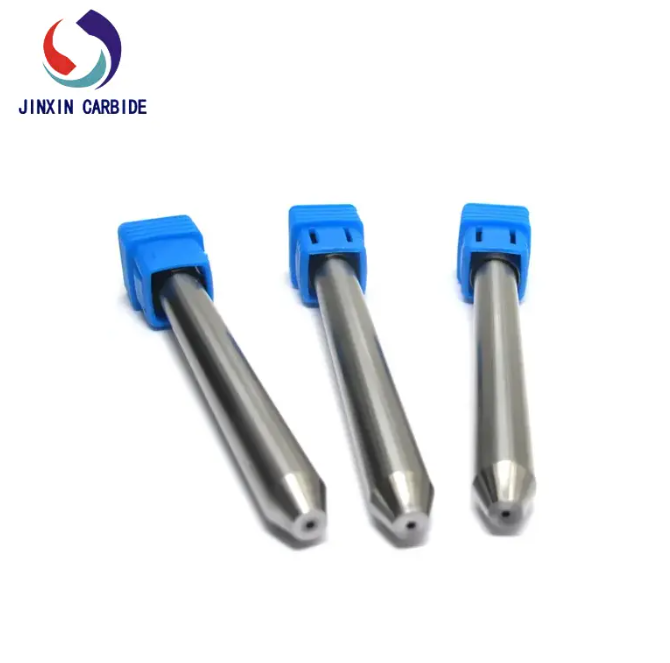

● Cutting Tools: It is used to make high-performance cutting tools like drill bits, saw blades, and milling cutters. Its hardness allows these tools to maintain sharp edges for longer.

● Abrasives: Tungsten carbide's toughness makes it ideal for abrasive applications, like grinding, polishing, and sanding tools.

● Mining and Heavy Machinery: Its resistance to wear and high-pressure environments makes tungsten carbide perfect for mining drills, earth-moving equipment, and heavy machinery components.

How is Tungsten Carbide Used in Jewelry?

Tungsten carbide has gained popularity in the jewelry market, especially for:

● Wedding Rings and Watch Cases: Tungsten carbide's scratch-resistant and durable nature makes it a popular choice for wedding rings and watch cases. It maintains a shiny finish and resists scratches better than other metals.

● Benefits for Consumers: Tungsten carbide jewelry is more affordable than gold or platinum, while still offering superior durability. Consumers appreciate its lasting shine, affordability, and scratch-resistance.

Tungsten Carbide in Sports and Leisure

Tungsten carbide's density and toughness make it suitable for various products in the sports and leisure sector:

● Trekking Poles and Cleats: Tungsten carbide tips are used in trekking poles for durability and grip on rocky terrains.

● Fishing Weights: Its weight and density make it an excellent material for fishing weights, helping them sink quickly and efficiently.

Why is Tungsten Carbide Used in High-Precision Tools?

Tungsten carbide plays a critical role in applications that require extreme precision:

● Surgical Tools: Its hardness and sharpness make it perfect for surgical instruments, allowing for fine, precise cuts during operations.

● Electronics: Tungsten carbide is used in the electronics industry for manufacturing small, high-precision components.

● Aerospace Engineering: It is used in components such as turbine blades, where extreme heat resistance and strength are essential. Its durability ensures that parts perform reliably under high stress and temperature conditions.

Conclusion

Tungsten carbide is essential in industries like cutting, machining, mining, and jewelry due to its hardness and durability. Its ability to withstand high pressure and extreme conditions makes it a preferred material in many applications. As technology advances, tungsten carbide's relevance and potential in various sectors will only continue to grow, ensuring its place in modern manufacturing and beyond. Welcome to Jingxin Consulting Products!

FAQ

Q: What are the Benefits of Tungsten Carbide?

A: Tungsten carbide offers exceptional durability, high hardness, resistance to heat and corrosion, making it ideal for heavy-duty applications.

Q: How Does Tungsten Carbide Compare to Diamond?

A: Tungsten carbide is nearly as hard as diamond but is more durable in high-stress environments. While diamond is harder, tungsten carbide is more resistant to impact and wear.

Q: Can You Weld Tungsten Carbide?

A: Tungsten carbide is difficult to weld due to its hardness. Specialized techniques, like high-temperature processes, are required for welding.

Q: Is Tungsten Carbide Recyclable?

A: Yes, tungsten carbide can be recycled. The material is highly valuable and is commonly reused in manufacturing tools, reducing environmental impact and production costs.

+86-18073319589

+86-18073319589