Tungsten Carbide is known for its durability, but does it tarnish over time? Understanding this is crucial, especially for those using it in industrial tools and jewelry. In this post, we'll explore whether Tungsten Carbide tarnishes, what causes it, and how to maintain its appearance. You'll learn how different factors impact its longevity and resistance to tarnishing.

Why Does Tungsten Carbide Not Tarnish Easily?

Tungsten Carbide is widely known for its impressive resistance to tarnishing, making it a go-to material for industrial tools and jewelry.

High Durability of Tungsten Carbide

Tungsten Carbide stands out due to its exceptional durability. Unlike many other metals, it resists corrosion and tarnishing because it maintains its surface integrity over time. This high resistance makes it perfect for tools, drill bits, and even jewelry, where longevity and a polished appearance are essential. The material's toughness allows it to withstand harsh environments without showing signs of wear or tarnish. Whether used in the aerospace industry, mining, or as a part of everyday jewelry, Tungsten Carbide remains pristine under normal conditions, offering durability that lasts for years.

Chemical Stability of Tungsten Carbide

Tungsten Carbide's chemical stability plays a significant role in its resistance to tarnishing. It's generally non-reactive and doesn’t easily bond with oxygen or other elements that cause corrosion. Unlike metals such as iron or copper, Tungsten Carbide remains unaffected by moisture, air, and common environmental factors that might cause rust or tarnish. This unique quality ensures it stays intact and keeps its shine, even under typical usage conditions. Its stable atomic structure allows it to resist tarnishing and degradation, making it ideal for high-performance environments where reliability is crucial.

In fact, Tungsten Carbide is often used in high-temperature applications, where other metals would degrade or tarnish. This level of stability makes it the preferred material in industries requiring both strength and longevity.

Factors That Can Cause Tarnishing in Tungsten Carbide

Though Tungsten Carbide is highly resistant to tarnishing, certain conditions can still lead to oxidation or tarnishing in some cases.

Extreme Temperatures

Tungsten Carbide is known for its ability to withstand high temperatures, but prolonged exposure to heat above 600°C can cause oxidation. When subjected to these extreme temperatures, Tungsten Carbide's surface can start to react with oxygen in the air, leading to tarnishing. In industrial applications, such as cutting or grinding tools, heat generated by friction or external sources can cause oxidation on the surface. However, Tungsten Carbide generally remains unaffected at temperatures below this threshold, retaining its shine and hardness in most everyday uses.

Exposure to Moisture and Oxygen

While Tungsten Carbide is generally resistant to oxidation in normal conditions, exposure to moisture and oxygen for extended periods can cause tarnishing in some cases. This is more likely to occur in alloys that contain higher amounts of binder metals, like cobalt or nickel, which are more prone to oxidation. In rare cases, if Tungsten Carbide is left in a damp or humid environment for too long, it may start to show signs of surface wear. This is less of an issue in dry, controlled conditions but should be considered when using Tungsten Carbide in environments with high humidity or fluctuating temperatures.

Chemical Exposure

Tungsten Carbide's surface is highly resistant to corrosion, but it can be affected by exposure to certain chemicals. Strong acids or alkalis can break down the protective oxide layer on Tungsten Carbide, leading to tarnishing. For instance, contact with acidic solutions or harsh cleaning agents can corrode the material, particularly if the alloy contains cobalt or other metals that are susceptible to chemical reactions. It's essential to avoid prolonged contact with such substances to preserve the material's appearance and longevity. Regular cleaning with mild soap and water helps maintain the integrity of the surface, preventing chemical degradation.

In industrial settings, where Tungsten Carbide tools are exposed to chemicals, special care should be taken to ensure that the material is cleaned and stored properly to avoid damage. This is particularly true in environments where chemicals or abrasive materials are frequently used.

Mechanical Damage and Wear

Tungsten Carbide is incredibly hard, but it's not entirely impervious to mechanical damage. In certain conditions, such as heavy wear, scratches, or impacts, the material can become vulnerable to tarnishing. Damage to the surface can expose the underlying layers to environmental factors like moisture, oxygen, or chemicals, which can initiate tarnishing or oxidation. Regular maintenance, proper handling, and avoiding excessive force can help reduce the risk of mechanical damage, preserving Tungsten Carbide's durability and appearance.

Despite these factors, Tungsten Carbide remains one of the most durable materials available, with proper care ensuring it maintains its resistance to tarnishing over time.

Tungsten Carbide Tarnish in Industrial Tools and Jewelry

Tungsten Carbide's exceptional durability and resistance to tarnishing make it an ideal choice for both industrial tools and jewelry.

Why Tungsten Carbide Is Ideal for Jewelry

Tungsten Carbide is a popular choice for jewelry, especially rings and wedding bands, due to its remarkable resistance to tarnishing. Unlike many other metals, Tungsten Carbide doesn't easily react with air or moisture. This makes it perfect for daily wear, where it can maintain its shiny appearance and resist the wear and tear that typically tarnish other metals. Tungsten Carbide's hardness ensures that jewelry remains free from scratches and tarnish, keeping it looking as good as new for years.

Does Tungsten Carbide Jewelry Tarnish Over Time?

Under normal conditions, Tungsten Carbide jewelry is highly resistant to tarnishing. The material's non-reactive nature means that, even with daily exposure to moisture, sweat, or environmental factors, it remains unaffected. Tarnishing in Tungsten Carbide jewelry is very rare unless the piece is exposed to extreme conditions, such as high heat or harsh chemicals. This makes Tungsten Carbide jewelry an excellent long-term investment for anyone looking for low-maintenance, durable pieces that stay looking polished.

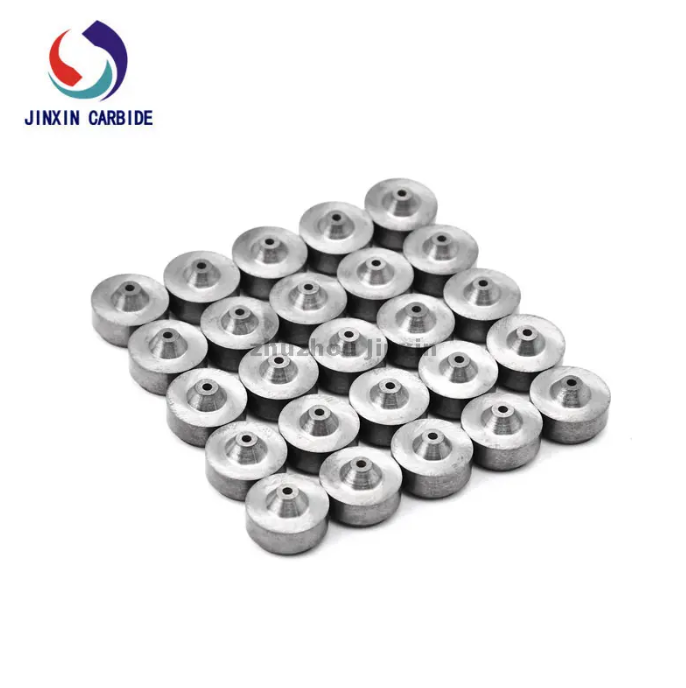

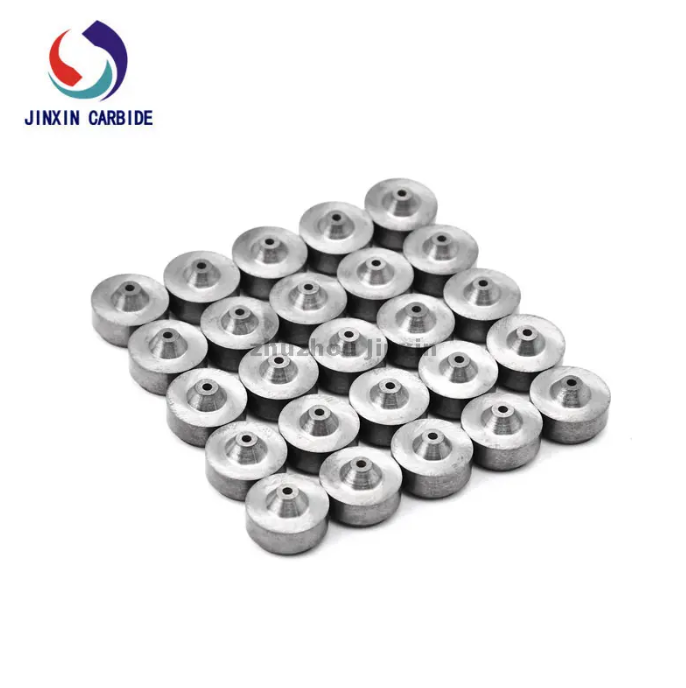

Why Tungsten Carbide is Used in Industrial Tools

Tungsten Carbide's strength, wear resistance, and resistance to tarnishing make it ideal for a wide range of industrial tools. It is commonly used in cutting tools, drill bits, saw blades, and machine inserts. The material’s durability ensures that it can withstand constant wear and tear without losing its sharpness or effectiveness. Tungsten Carbide's resistance to tarnishing also means that tools made from it maintain their performance over time, even when exposed to harsh industrial environments.

Does Tungsten Carbide Tarnish in Tool Use?

In industrial settings, Tungsten Carbide tools are designed to endure the most demanding conditions. While some exposure to heat, moisture, or abrasive materials can cause surface wear, tarnishing is rare in Tungsten Carbide tools under normal usage. The material's hardness and corrosion resistance make it highly effective, even in environments with high temperatures or exposure to chemicals. However, it's important to maintain and clean these tools regularly to ensure they continue to perform at their best.

How to Care for Tungsten Carbide to Prevent Tarnishing

Tungsten Carbide is highly durable and resistant to tarnishing, but proper care can ensure it stays looking pristine for longer.

Proper Cleaning Methods

To keep Tungsten Carbide tools or jewelry in great condition, regular cleaning is essential. For tools, use a soft cloth to wipe away dirt and debris after each use. If there's built-up grime, wash it with warm water and mild soap. Avoid using harsh chemicals or abrasive materials that can scratch or damage the surface. For jewelry, a soft cloth or microfiber towel is best for cleaning. Mild soap and water can also be used for a deeper clean, followed by drying it thoroughly.

Storage Tips to Avoid Tarnishing

How and where you store Tungsten Carbide can significantly impact its longevity. To prevent exposure to tarnishing factors, store Tungsten Carbide tools in a dry place away from moisture. Keep them in a protective case or container to avoid scratches or other damage. For jewelry, store it in a velvet or cloth pouch, away from chemicals or extreme heat sources. When not in use, keep Tungsten Carbide items in a cool, dry environment to maintain their shiny appearance and prevent any potential tarnishing.

Conclusion

Tungsten Carbide is highly resistant to tarnishing but can tarnish under extreme conditions. Its durability makes it ideal for both jewelry and industrial tools. Proper care and maintenance ensure it remains in top condition, extending its longevity and appearance.

Jingxin has years of experience in production and sales of tungsten carbide tools. If you want to know more about tungsten carbide, feel free to contact us anytime with your inquiries.

FAQ

Q: Can Tungsten Carbide Tarnish in Water?

A: Tungsten Carbide is resistant to tarnishing when exposed to water, making it ideal for everyday use, even in wet conditions.

Q: Does Tungsten Carbide Rust in Saltwater?

A: Tungsten Carbide is stable in saltwater but should not be exposed for extended periods to avoid potential degradation of its surface.

Q: How Can I Restore the Shine of My Tungsten Carbide Jewelry?

A: To restore the shine, simply clean it with a soft cloth and mild soap solution. Avoid harsh chemicals or abrasive materials.

Q: Is Tungsten Carbide Safe to Wear in Daily Activities?

A: Yes, Tungsten Carbide is safe for daily wear. Its resistance to tarnishing and scratching makes it an excellent material for rings and bracelets.

+86-18073319589

+86-18073319589