When it comes to industrial applications that involve high pressure, extreme temperatures, and exposure to abrasive or corrosive materials, the quality and durability of the components used are crucial. In particular, tungsten carbide plungers have gained significant recognition in various industries due to their unique combination of strength, wear resistance, and durability. These plungers are indispensable in applications where failure or excessive wear could lead to expensive repairs, safety risks, or loss of productivity.

What Are Tungsten Carbide Plungers?

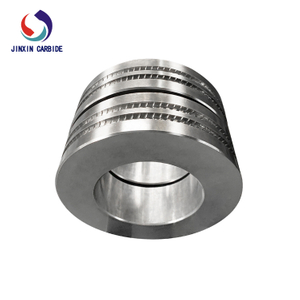

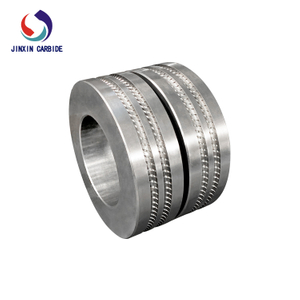

Tungsten carbide plungers are mechanical components used in various industrial processes, including hydraulic systems, pumps, and valves. These plungers play a vital role in controlling the flow of liquids, gases, and other materials, often under high pressure. Made from a combination of tungsten carbide (WC) and a binder material such as cobalt or nickel, these plungers are known for their exceptional hardness, durability, and resistance to wear and corrosion.

The tungsten carbide material is formed through a sintering process, where tungsten powder is heated to extremely high temperatures, creating a dense, rigid, and durable material. This makes tungsten carbide plungers ideal for operations in harsh environments where other materials might fail due to high wear rates, extreme temperatures, or chemical exposure.

Key Properties of Tungsten Carbide That Make It Ideal for Harsh Environments

Tungsten carbide's unique properties make it well-suited for environments where equipment is exposed to extreme conditions. Let’s explore these key properties and why they are so beneficial in harsh environments.

1. Unmatched Hardness

One of the most critical properties of tungsten carbide is its extreme hardness. Tungsten carbide is one of the hardest materials available, second only to diamonds. This hardness makes it highly resistant to wear and tear, especially in abrasive environments. When used in plungers, this hardness allows them to withstand constant friction and high-impact conditions without losing their shape or functionality.

In applications where plungers are subjected to repetitive motion and friction, such as in pumps or hydraulic systems, the hardness of tungsten carbide ensures that the plunger can maintain its precision and integrity for extended periods. This resistance to wear is crucial for preventing early failure and minimizing the need for maintenance or part replacements.

2. Excellent Wear and Abrasion Resistance

In high-pressure environments, the materials in contact with each other are often subject to constant friction, which can cause wear over time. Tungsten carbide plungers have excellent wear resistance, even in applications where they come into contact with abrasive substances such as sand, dirt, and other particulates. This ability to resist abrasive wear ensures that the plungers retain their shape and functionality for longer periods, even in challenging conditions.

For instance, in the oil and gas industry, where plungers are exposed to harsh chemicals and abrasive fluids, tungsten carbide plungers can continue to operate effectively, minimizing downtime and extending the lifespan of the equipment.

3. High Temperature Resistance

Many industrial applications, such as those in the oil, gas, and chemical industries, require equipment that can withstand high temperatures. Tungsten carbide plungers excel in this area, as tungsten carbide can tolerate temperatures well above 1,000°C (1,832°F) without losing its structural integrity.

This high-temperature resistance is crucial in environments where plungers are exposed to elevated heat, such as in engines, pumps, and valves used in the chemical processing industry. Tungsten carbide’s ability to maintain its hardness and strength under such conditions ensures the reliable performance of components even in extreme heat.

4. Corrosion Resistance

In industries where equipment comes into contact with corrosive substances such as acids, alkalis, or saltwater, corrosion resistance is an essential property. Tungsten carbide plungers offer excellent resistance to chemical corrosion, making them ideal for use in chemical processing, marine applications, and other environments where exposure to harsh chemicals is common.

Tungsten carbide's corrosion resistance helps to prevent degradation and failure of plungers, which could otherwise lead to leaks, inefficiencies, and costly maintenance. In harsh chemical environments, a tungsten carbide plunger ensures that the equipment operates effectively without being compromised by corrosive materials.

5. High Density and Smooth Surface Finish

Tungsten carbide has a high density, meaning that it is a very solid and stable material. This property contributes to the stability and durability of tungsten carbide plungers, allowing them to operate more effectively in high-pressure applications. The high density also ensures that the plungers can absorb impact forces without deforming or breaking.

Additionally, the smooth surface finish of tungsten carbide plungers helps to reduce friction between moving parts, preventing damage to the plunger or surrounding components. This smoothness also contributes to the overall efficiency of the system, reducing wear and energy consumption.

Applications of Tungsten Carbide Plungers in Harsh Environments

Tungsten carbide plungers are used in various industries where components are exposed to extreme pressures, temperatures, and corrosive or abrasive substances. Let’s take a closer look at some of the key industries that benefit from these plungers.

1. Oil and Gas Industry

The oil and gas industry is one of the most demanding sectors when it comes to equipment durability. Equipment in this industry is often exposed to high pressures, extreme temperatures, and abrasive substances, such as sand and dirt, which can cause rapid wear and tear.

Tungsten carbide plungers are commonly used in hydraulic pumps, injectors, and pressure regulators to help control the flow of fluids under high-pressure conditions. The plungers’ ability to withstand extreme pressure and abrasive fluids without degrading makes them ideal for hydraulic fracturing, offshore drilling, and other oil and gas applications. By reducing the frequency of maintenance and part replacements, tungsten carbide plungers improve the overall efficiency and cost-effectiveness of oil and gas operations.

2. Chemical Processing

In chemical processing, equipment is often exposed to aggressive chemicals, acids, and alkalis that can cause damage to components made from less durable materials. Tungsten carbide plungers are ideal for this industry because of their corrosion resistance and wear resistance.

These plungers are used in pumps, valves, and pressure vessels that handle corrosive fluids. Tungsten carbide plungers maintain their integrity and reliability over time, ensuring that chemical processing systems operate smoothly without the risk of leaks or equipment failure caused by chemical degradation.

3. Automotive Industry

The automotive industry requires high-performance components that can withstand high temperatures and pressures, especially in fuel injection systems, hydraulic pumps, and braking systems. Tungsten carbide plungers are used in fuel systems to ensure accurate fuel delivery under high pressure.

Additionally, in hydraulic braking systems and pressure regulators, tungsten carbide plungers provide the durability and wear resistance needed to ensure the safety and performance of the vehicle under extreme conditions.

4. Mining Industry

Mining operations involve handling abrasive materials such as rock, sand, and minerals, which can quickly wear down standard plunger materials. Tungsten carbide plungers are commonly used in mining equipment such as hydraulic mining machines, slurry pumps, and drilling rigs, where they are exposed to abrasive fluids and high pressures.

Due to their abrasion resistance and high strength, tungsten carbide plungers are able to maintain their performance in these harsh environments, reducing downtime and improving the overall efficiency of mining operations.

5. Marine Applications

In marine applications, equipment is exposed to saltwater, which is highly corrosive and can degrade many materials over time. Tungsten carbide plungers offer corrosion resistance in saltwater environments, making them suitable for use in marine pumps, seals, and valves.

The ability of tungsten carbide plungers to withstand both the abrasive nature of saltwater and the corrosive effects of salt makes them an invaluable component in marine engineering and offshore oil and gas platforms.

How to Choose the Right Tungsten Carbide Plunger

When selecting a tungsten carbide plunger for your application, consider the following factors:

Operating Pressure: Choose a plunger that can withstand the pressure conditions of your system.

Temperature Range: Make sure the plunger can operate within the required temperature range for your environment.

Chemical Exposure: Consider the type of chemicals the plunger will come into contact with to ensure that the material offers adequate corrosion resistance.

Abrasion Resistance: For applications involving abrasive fluids or particles, ensure that the plunger offers sufficient wear resistance.

Size and Fit: Ensure the plunger is properly sized and compatible with the system where it will be used.

Conclusion

Tungsten carbide plungers are the ideal solution for high-pressure applications in harsh environments. Their extreme hardness, wear resistance, high-temperature tolerance, and corrosion resistance make them perfect for industries such as oil and gas, chemical processing, automotive, and mining, where equipment is subjected to severe operating conditions. By choosing tungsten carbide plungers, manufacturers can ensure reliable performance, reduce downtime, and increase the efficiency of their systems. Whether you are dealing with high-pressure fluids, corrosive substances, or abrasive materials, tungsten carbide plungers are the trusted choice for long-lasting and high-performance components in harsh environments.

For more information about tungsten carbide plungers and to source high-quality components for your needs, consider contacting Changsha Jingxin Cemented Carbide Co., Ltd., a leader in manufacturing premium tungsten carbide products.

+86-18073319589

+86-18073319589