In the world of manufacturing, precision and durability are key factors that determine the success of any product. Whether it’s producing automotive parts, electronics, or consumer goods, manufacturers need components that can withstand high pressures, intense wear, and extreme temperatures. One such component that plays a crucial role in enhancing the performance of manufacturing processes is the carbide core pin.

But what exactly is a carbide core pin, and how does it help improve manufacturing processes? In this detailed guide, we’ll explore the definition, uses, benefits, and importance of carbide core pins in various industries. We’ll also take a closer look at why they are favored over other materials, their applications, and how they improve productivity and efficiency in modern manufacturing.

What Is a Carbide Core Pin?

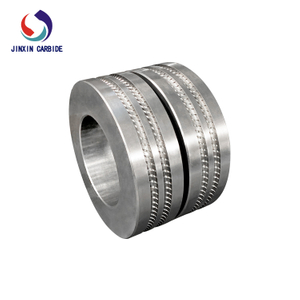

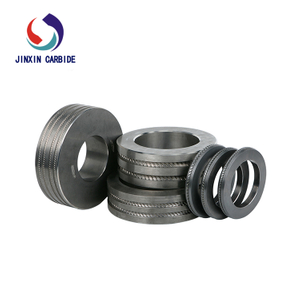

A carbide core pin is a specialized tool made primarily of cemented carbide, a highly durable and wear-resistant material that consists of fine particles of carbide (typically tungsten carbide) bound together with a metal binder, such as cobalt. These core pins are used in precision molding processes, particularly in industries like injection molding, die-casting, and forging.

Core pins are typically inserted into molds to create holes or cavities in molded parts. They are designed to withstand extreme mechanical and thermal stresses, making them an essential part of the manufacturing process for parts that require high precision and durability.

The Role of Carbide Core Pins in Manufacturing

Carbide core pins are primarily used in mold-making, particularly in industries where complex shapes or precise cavities are required. These core pins play an essential role in ensuring the final product has the desired properties. Their unique ability to resist wear, corrosion, and high temperatures makes them ideal for applications in which traditional materials, such as steel or aluminum, may not perform as well.

Core pins are often inserted into molds before the molding process begins. They are used to create internal voids or channels in parts, which is crucial for applications like making hollow plastic components or creating intricate designs. The use of carbide core pins in these processes ensures that the molds remain stable during the molding process, preventing any warping or dimensional inaccuracies.

How Carbide Core Pins Improve Manufacturing Processes

Carbide core pins offer significant improvements in various manufacturing processes. Let’s explore how they enhance efficiency, precision, and cost-effectiveness:

1. Enhanced Durability and Longevity

Carbide core pins are highly durable, outlasting traditional materials like steel and aluminum. Their high hardness and wear resistance enable them to withstand repeated stress, high pressure, and harsh environments, reducing the need for frequent maintenance, repairs, or replacements. This long lifespan cuts downtime and lowers operational costs for manufacturers.

2. Precision and Accuracy in Molding

Carbide core pins excel in producing precise cavities and holes with high dimensional accuracy, making them ideal for applications with tight tolerances. This precision is critical in industries like automotive, electronics, and aerospace, where even small imperfections can lead to product failures. Carbide core pins reduce the need for additional finishing processes, improving both product quality and manufacturing efficiency.

3. High Resistance to Heat and Corrosion

Many manufacturing processes, such as injection molding and die casting, involve high temperatures that can degrade less durable materials. Carbide core pins, however, are highly resistant to heat and corrosion, maintaining their shape and integrity even in extreme conditions. This heat resistance ensures that the pins remain functional and precise, particularly in high-stress industries like aerospace and automotive.

4. Reduced Friction and Wear

Carbide’s hardness and smooth surface reduce friction during the molding process, extending the life of both the core pin and the mold. This reduction in friction not only prevents premature wear but also enhances manufacturing efficiency, allowing parts to be molded more quickly with fewer interruptions.

5. Versatility Across Industries

Carbide core pins are used in diverse industries, thanks to their unique properties:

Automotive: In casting and molding engine components, gear parts, and housings.

Electronics: For intricate components like connectors and circuit boards.

Aerospace: For precision parts like turbine blades and structural components.

Medical: In creating highly accurate parts for medical devices and tools.

Applications of Carbide Core Pins

Carbide core pins play a vital role in a variety of manufacturing processes across multiple industries. Known for their exceptional hardness, wear resistance, and ability to maintain tight tolerances, these core pins are used to create precise features in molded, forged, and stamped components. Below are some of the most common applications of carbide core pins, which demonstrate their versatility and indispensability in manufacturing high-quality parts.

1. Injection Molding

Injection molding is a widely used manufacturing process for creating plastic parts, and carbide core pins are crucial to achieving high precision in this process. Carbide core pins are employed to create hollow cavities or specific internal features in molded parts. By using carbide core pins, manufacturers can ensure the following benefits:

Accuracy: Carbide’s hardness allows for high precision, ensuring that internal cavities and complex shapes are formed consistently and accurately.

Durability: Injection molding often involves repeated cycles, and carbide’s wear resistance makes it ideal for withstanding prolonged use without significant degradation.

Fine Details: Carbide core pins can create intricate and fine features in molded plastic parts, which is especially important in industries like automotive, electronics, and medical devices.

Example Use: In automotive components, injection molding with carbide core pins is often used to create hollow parts like dashboard inserts, air ducts, and internal plastic housings.

2. Die-Casting

Die-casting is a metal casting process that involves forcing molten metal into a mold under high pressure. Carbide core pins are used in die-casting to form internal features or cavities in metal parts. These pins are essential for creating complex shapes and improving the overall quality of the die-cast parts.

Benefits in Die-Casting:

High-Temperature Resistance: Carbide core pins can endure the high temperatures associated with molten metals, allowing manufacturers to produce parts with high precision and strength.

Complex Geometry: Carbide core pins enable the creation of intricate internal features, such as hollow sections or channels, which would otherwise be difficult to achieve with other materials.

Extended Tool Life: The hardness and wear resistance of carbide significantly extend the life of die-casting tools, reducing downtime and maintenance costs.

Example Use: Carbide core pins are often used in die-casting engine parts, such as cylinder heads or engine blocks, where precise internal cavities are required for air or fuel flow.

3. Stamping and Forging

In stamping and forging, carbide core pins are used in tools and dies to create specific cavities, channels, or features in metal parts. The stamping process involves pressing a material (usually metal) into a mold to form a desired shape, while forging uses compressive force to shape the material. Carbide core pins help ensure that the parts meet precise design specifications, especially in industries where dimensional accuracy is critical.

Benefits in Stamping and Forging:

Precision: Carbide core pins are used to form intricate features like holes, channels, and grooves in stamped or forged parts with high precision.

Wear Resistance: Stamping and forging processes involve high-pressure conditions, so carbide’s durability ensures that the core pins last longer and maintain performance across multiple cycles.

Tight Tolerances: Carbide core pins help achieve the tight tolerances required for parts that must fit together accurately, such as in the automotive or aerospace industries.

Example Use: In the automotive industry, carbide core pins are used to create the complex shapes and internal features of stamped metal parts, like car door panels, structural components, or brackets.

4. Plastic Molding

Carbide core pins are highly valuable in plastic molding, particularly when creating parts with specific internal features. These pins are designed to form precise holes, cavities, or intricate designs in plastic components, ensuring high-quality, defect-free products.

Benefits in Plastic Molding:

High-Precision Holes and Cavities: Carbide core pins can create fine details such as small holes, intricate designs, or complex internal features that are critical in industries such as electronics, medical devices, and consumer goods.

Enhanced Surface Finish: Carbide’s smooth surface helps in molding plastic parts with excellent surface quality, reducing the need for secondary finishing processes.

Longer Service Life: Carbide's superior wear resistance increases the longevity of the core pins, reducing the frequency of tool replacements and maintenance downtime.

Example Use: In the production of medical devices, carbide core pins are used to create precise cavities in plastic components such as syringes, inhalers, or IV connectors, which require a high level of accuracy for functionality and safety.

5. Mold Inserts

Carbide core pins are often used as mold inserts in manufacturing applications that demand high wear resistance. Mold inserts are components that are placed in a mold to provide specific features or attributes, and carbide is an ideal material due to its hardness and resistance to wear from high-pressure molding processes.

Benefits of Using Carbide in Mold Inserts:

Durability: Carbide mold inserts are highly durable, making them ideal for high-volume production runs where mold longevity is crucial.

Resistance to Abrasive Materials: In some molding processes, abrasive materials are used, which can rapidly wear down tools. Carbide’s exceptional wear resistance makes it perfect for forming parts from these materials.

Complex Designs: Carbide core pins used as mold inserts can create complex features like undercuts, which are necessary for producing parts with intricate shapes or multiple cavities.

Example Use: Carbide mold inserts are commonly used in industries like electronics and automotive, where precision and durability are paramount. For example, they might be used to form parts such as connectors or electrical housings that require complex features.

Conclusion

Carbide core pins are indispensable tools in modern manufacturing, offering unmatched precision, wear resistance, and durability across a wide range of applications. From injection molding to die-casting, stamping, and plastic molding, these core pins are crucial for creating complex, high-quality parts that meet the demanding standards of industries like aerospace, automotive, medical, and electronics. As manufacturing processes become more sophisticated and the demand for high-quality products increases, the importance of carbide core pins will continue to grow. By using these advanced tools, manufacturers can ensure greater efficiency, reduced downtime, and the production of high-performance components that meet the tightest tolerances and standards. Ultimately, carbide core pins are an essential component for achieving both operational excellence and product reliability in various industries, making them an invaluable asset in the manufacturing world.

+86-18073319589

+86-18073319589