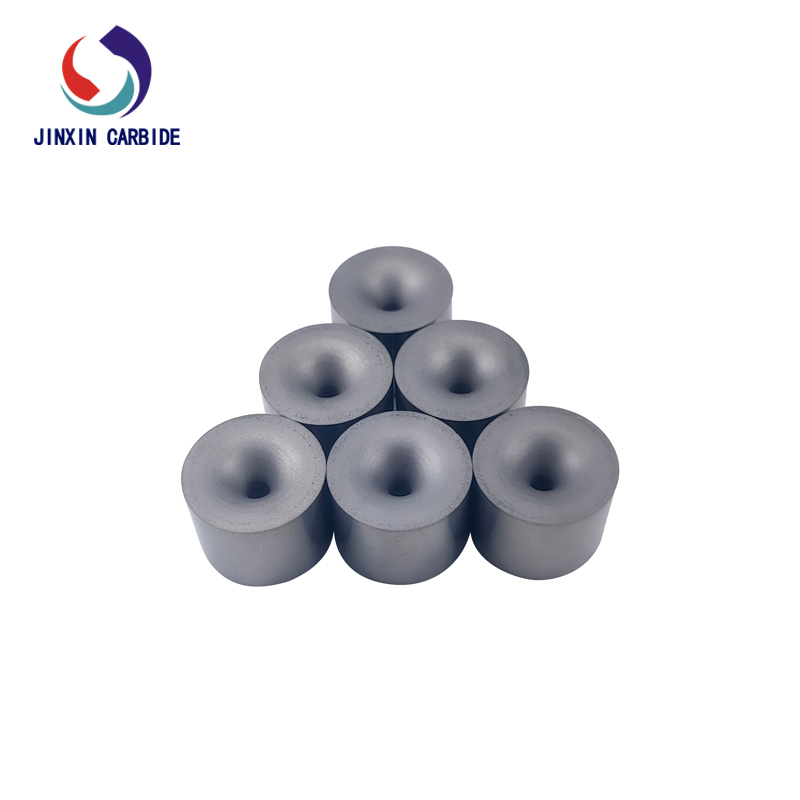

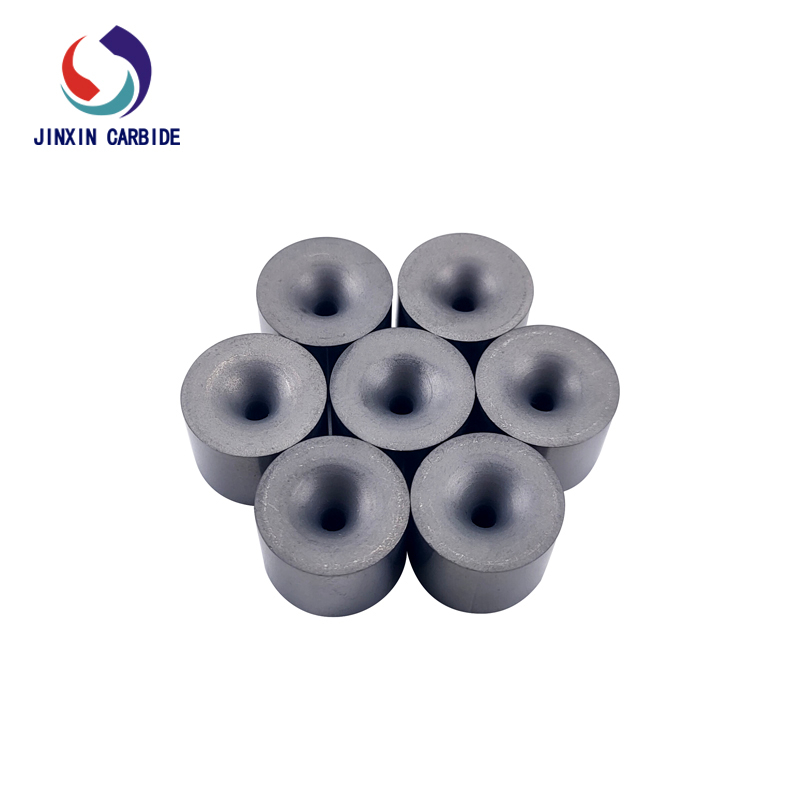

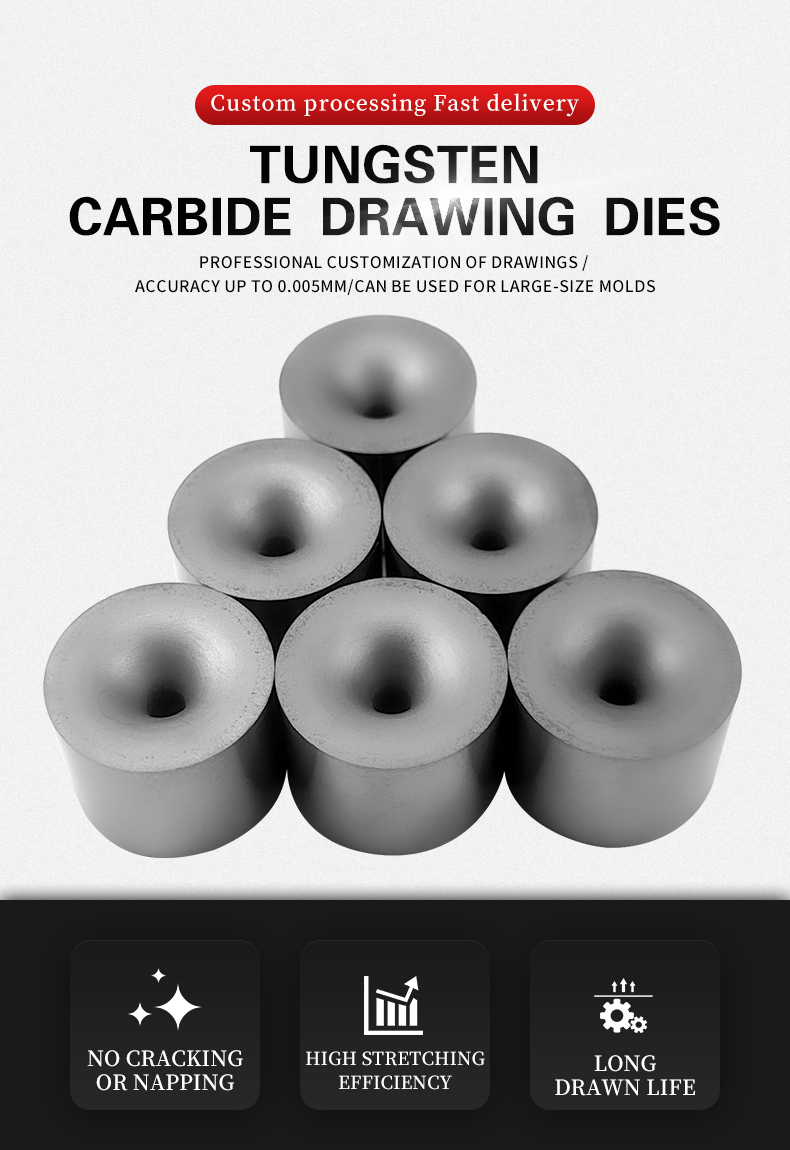

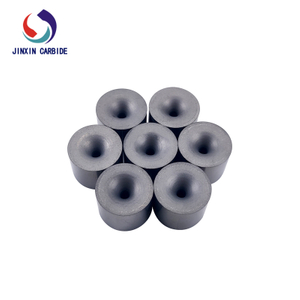

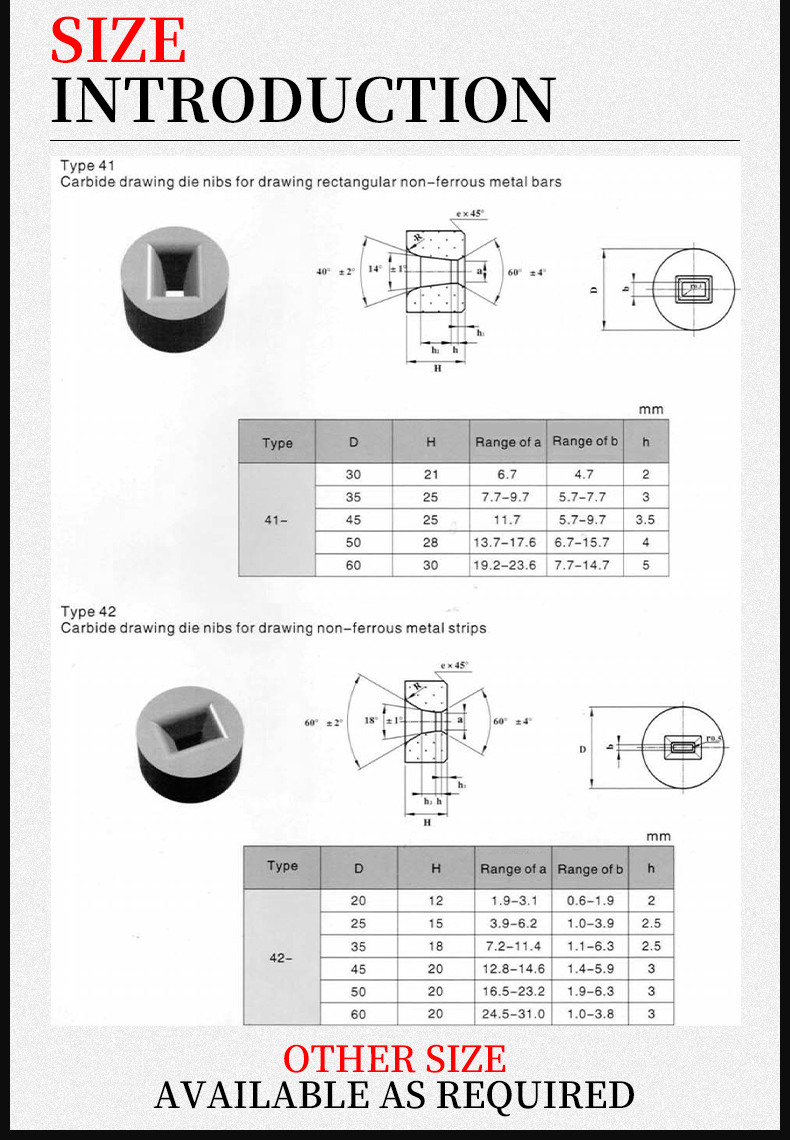

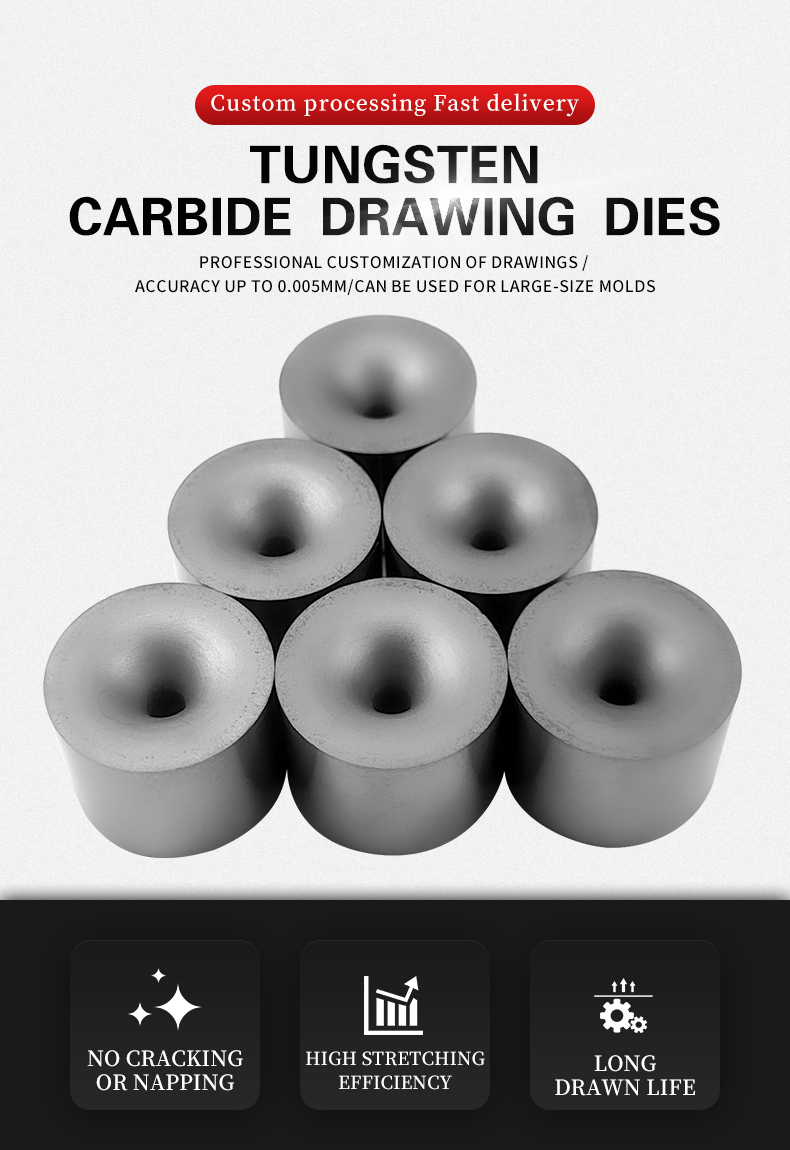

Tungsten carbide drawing dies description

Carbide drawing dies usually refers to the various metal wire drawing die, as well as the optical fiber drawing die. All drawing dies have a hole in the center of a certain shape, round, square, octagonal or some other special shape. The metal becomes smaller and even changes shape as it is pulled through the die hole. A steel die is sufficient to stretch a soft metal, such as gold and silver. The die may have several holes with different diameters. Drawing die widely used, such as electronics, radar, and TV, instruments and high precision wire and used in the aerospace and other commonly used tungsten, molybdenum wire, stainless steel wire, electric wire and cable wire and all kinds of alloy wire.

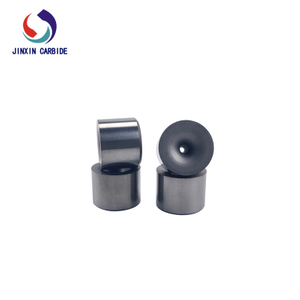

The function of each part for carbide drawing die

A carbide drawing die is composed of several key parts, each playing a vital role in achieving precise and smooth wire drawing performance. Understanding the function of each part helps ensure better die design, longer service life, and superior wire quality.

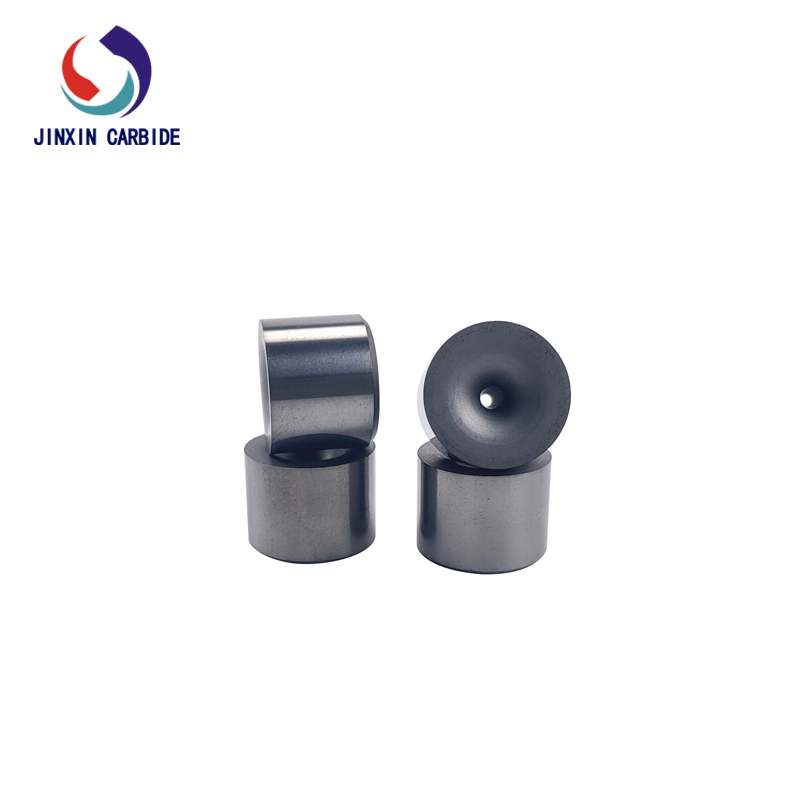

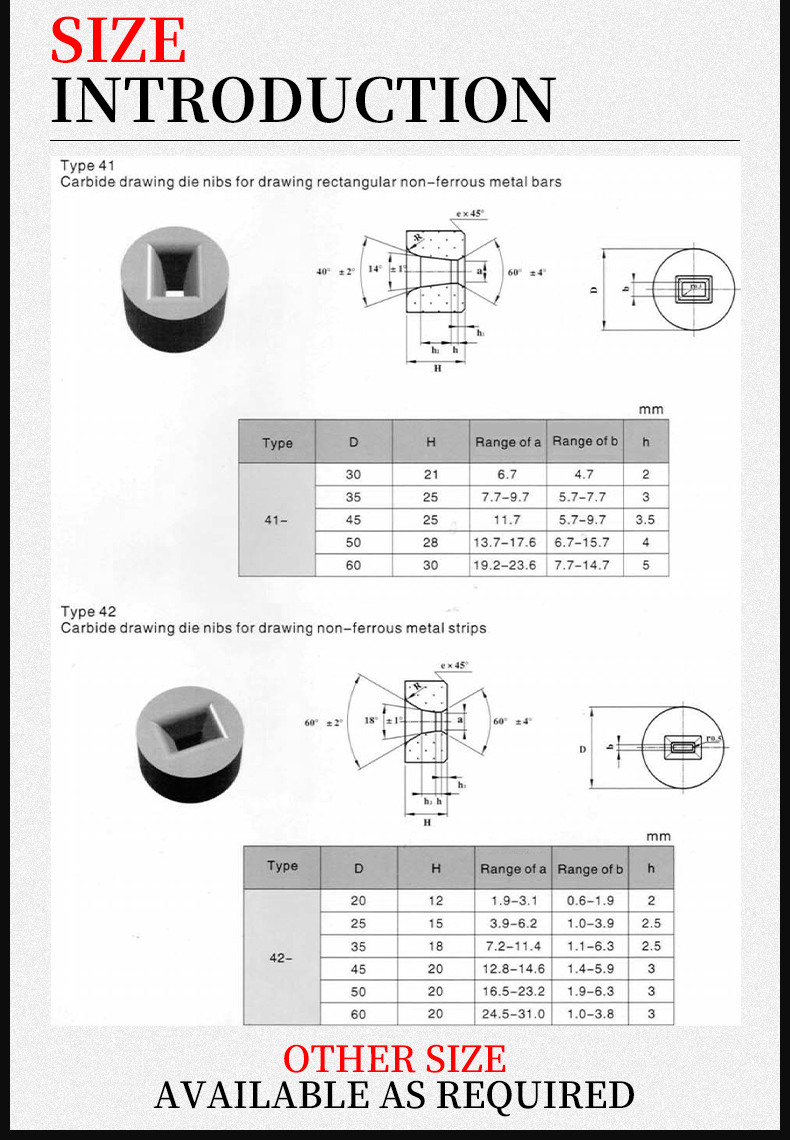

1.Entrance Zone (Bell Radius)

The entrance guides the wire into the die and helps align it properly. A well-polished entrance reduces friction and prevents damage to the wire surface.

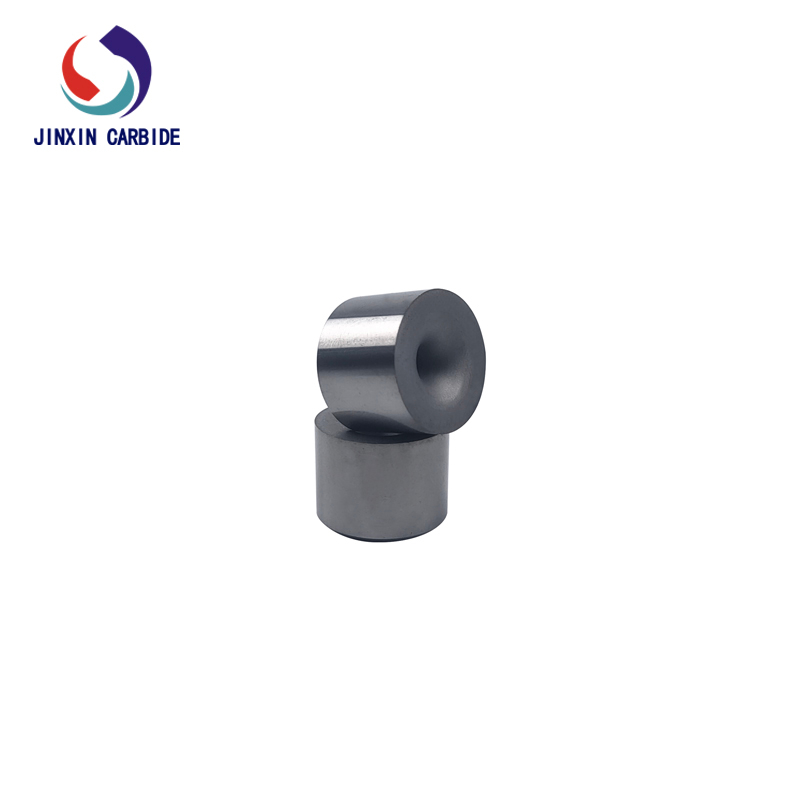

2.Approach Angle (Reduction Zone)

This is where the main deformation occurs. The metal wire is compressed and reduced in diameter as it passes through this angled section. The design of the approach angle directly affects the drawing force and surface finish.

3.Bearing Zone (Land)

The bearing zone determines the final diameter and roundness of the wire. It ensures consistent wire dimensions and provides stability during high-speed drawing.

4.Back Relief (Exit Zone)

The back relief allows the wire to exit smoothly from the die while minimizing stress and friction. Proper design of this area helps extend die life and improve production efficiency.

5.Case or Support Sleeve

The tungsten carbide nib is often mounted in a steel or carbide case to provide strength, rigidity, and thermal stability during continuous operation.

At Jinxin, every part of the carbide drawing die is precisely engineered and finely polished to deliver excellent wear resistance, high accuracy, and extended service life. Our strict quality control ensures stable performance for various wire materials, including tungsten, molybdenum, stainless steel, and alloy wires.

+86-18073319589

+86-18073319589