Manufacture Wholesale Tungsten Carbide Punch Needle

Sharpened tungsten carbide rods usually refer to the sharpening of tungsten carbide rods in the process of machining to make one or both ends sharp or fine.

Sharpened tungsten carbide rods are widely used in many fields, such as:

Stamping Dies – For high-precision punching of metal sheets.

Mold Industry – Used in progressive dies and forming dies.

Electronics & Automotive – Precision punching of small parts and components.

Industrial Equipment – Wear-resistant tooling and custom die components.

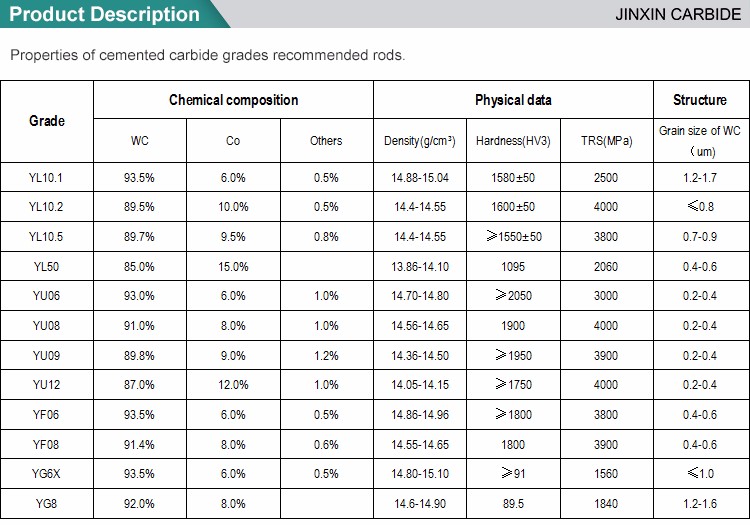

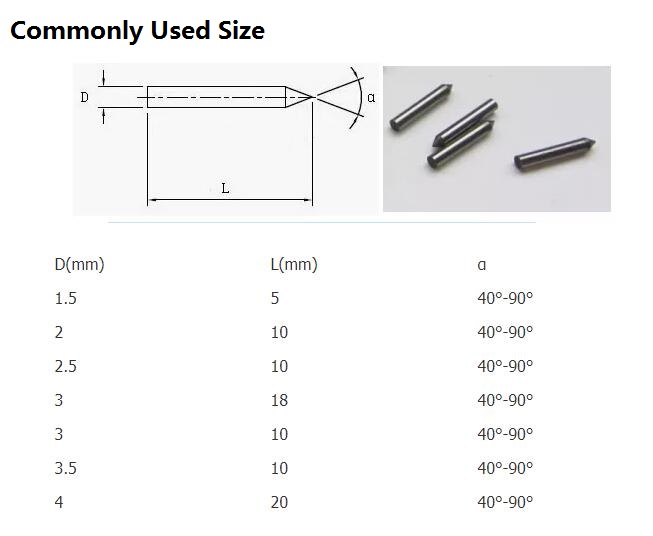

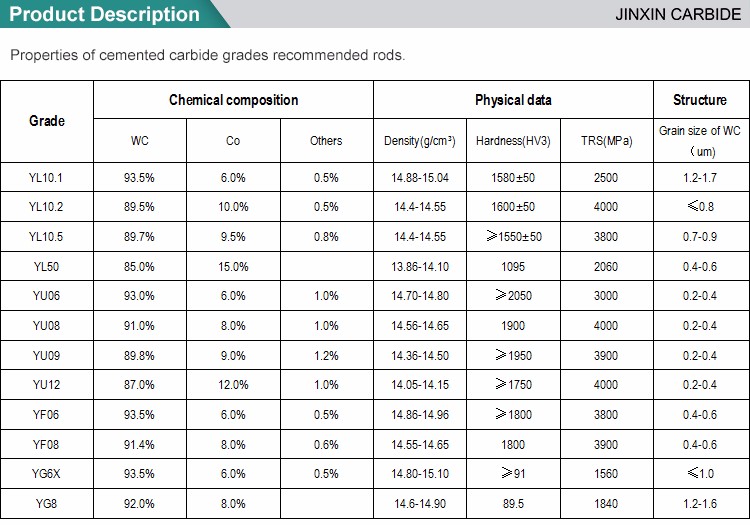

Sharpened tungsten carbide rods specification

Material: 100% Virgin Tungsten Carbide

Grade Options: customized grades available

Hardness: HRA 89–93

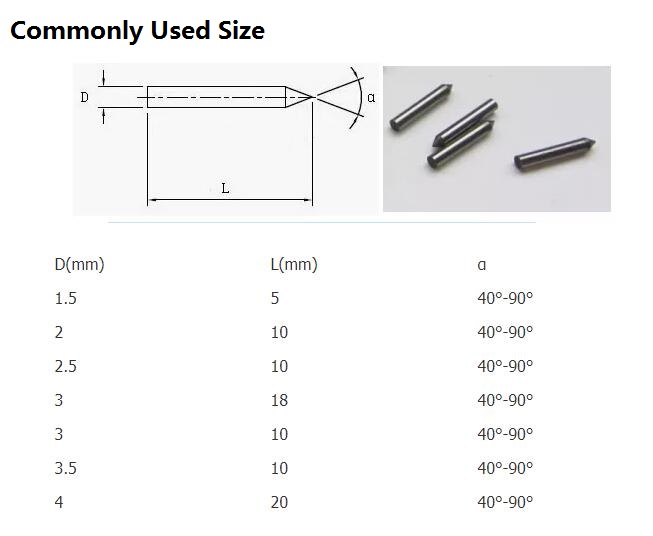

Diameter Range: 0.5 mm – 20 mm (custom sizes available)

Length Range: 10 mm – 200 mm

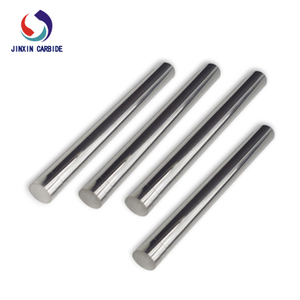

Sharpened tungsten carbide rods photos

+86-18073319589

+86-18073319589