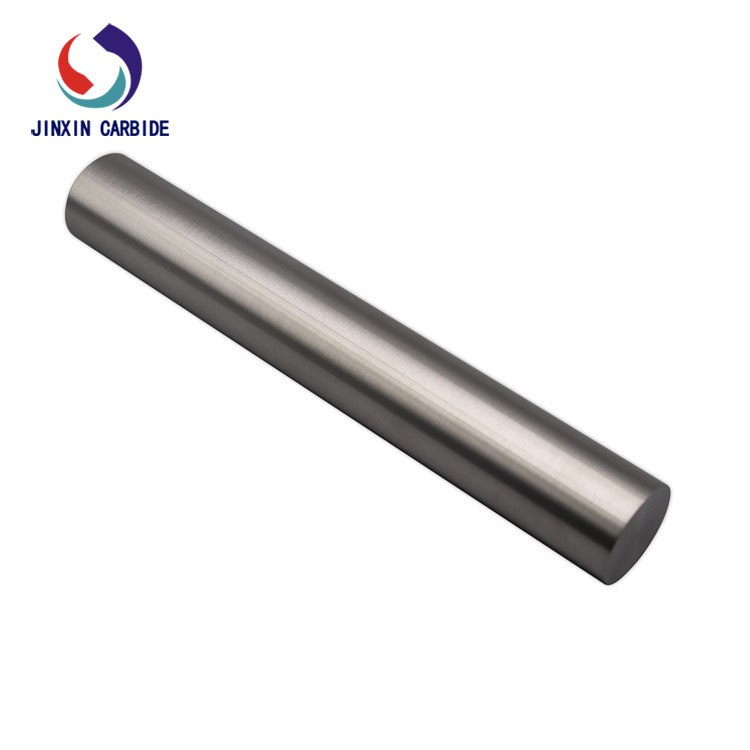

95W-Ni-Fe Tungsten Alloy Rods for Counterweight

Tungsten alloy rods are made of high specific gravity tungsten alloy and have good mechanical properties such as high tensile strength, high temperature resistance, good ductility, etc. They are widely used in industry.In machining, for example, in the process of casting cannon barrels, tungsten alloy rods are mainly used to expand round holes by drilling holes with single point cutting tools, thus obtaining round holes with precise diameters. Tungsten alloy rods can also be used to cut tapered round holes.

Applications

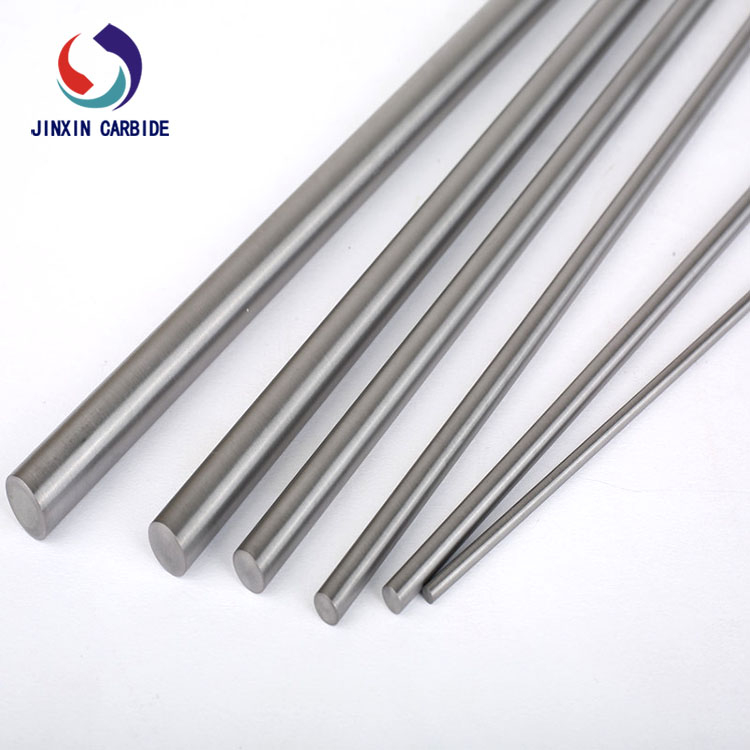

Typical applications for tungsten alloy rods include counterweights and balancing parts for aircraft maneuvering surfaces and rotor blades, counterweights for navigation systems, and balancing parts for flywheels and turbine engine crankshafts.

When mixed with heat resistant steel, tungsten alloy rods are used as high temperature resistant components in guns, cannons, rockets, satellites, aircraft and ships.

Other applications include nuclear radiation shielding parts, gyro rotors, weapons manufacturing including armor piercing bullets, and high temperature resistant tools.

Tungsten alloy is widely used in electronic and electric light source industry, and also used in aerospace, casting, weapons and other departments to make rocket nozzle, die casting mold, armor piercing projectile core, contact, heating element and heat insulation screen.

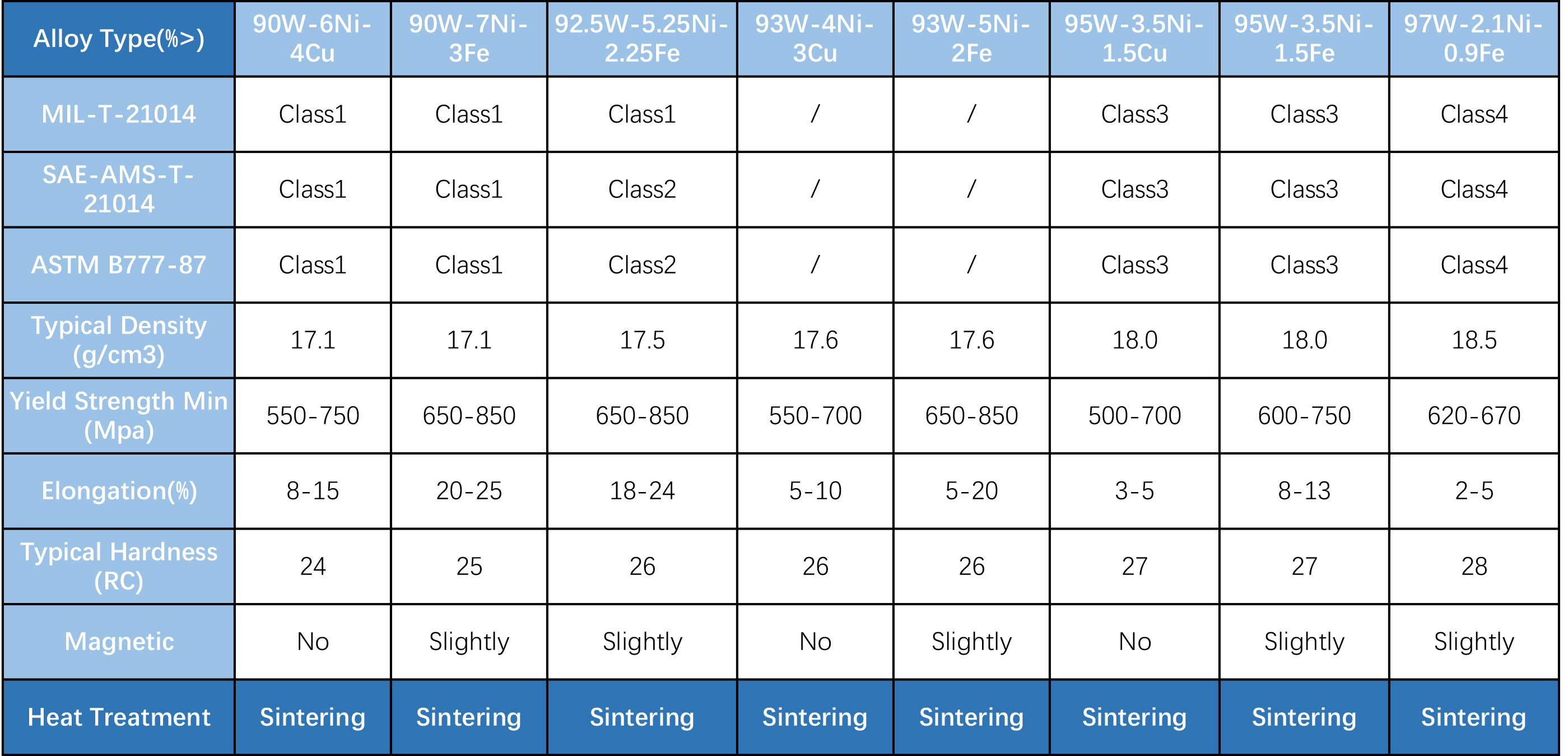

Specifications

+86-18073319589

+86-18073319589