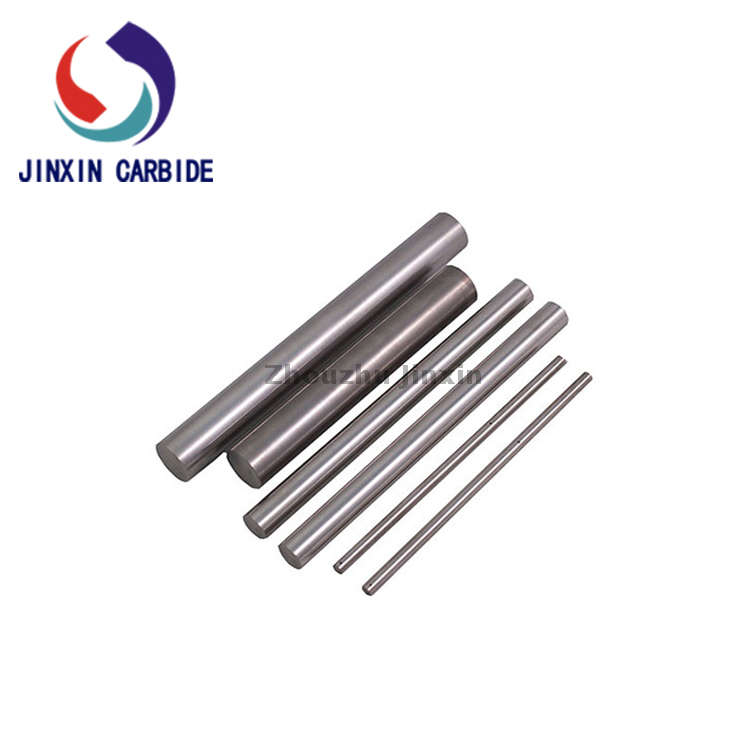

AMS7725 Tungsten Heavy Alloy Rods Wolfram Rod

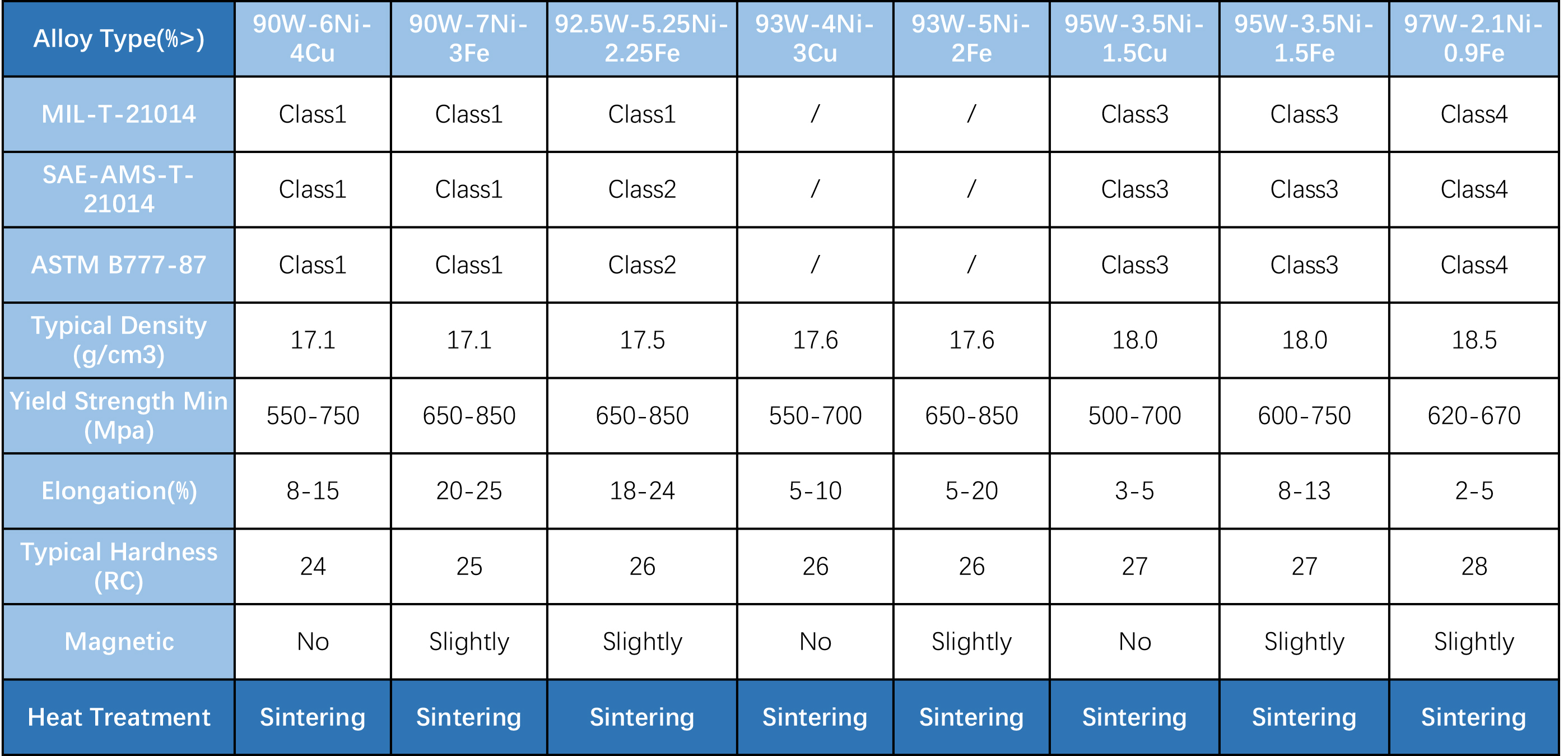

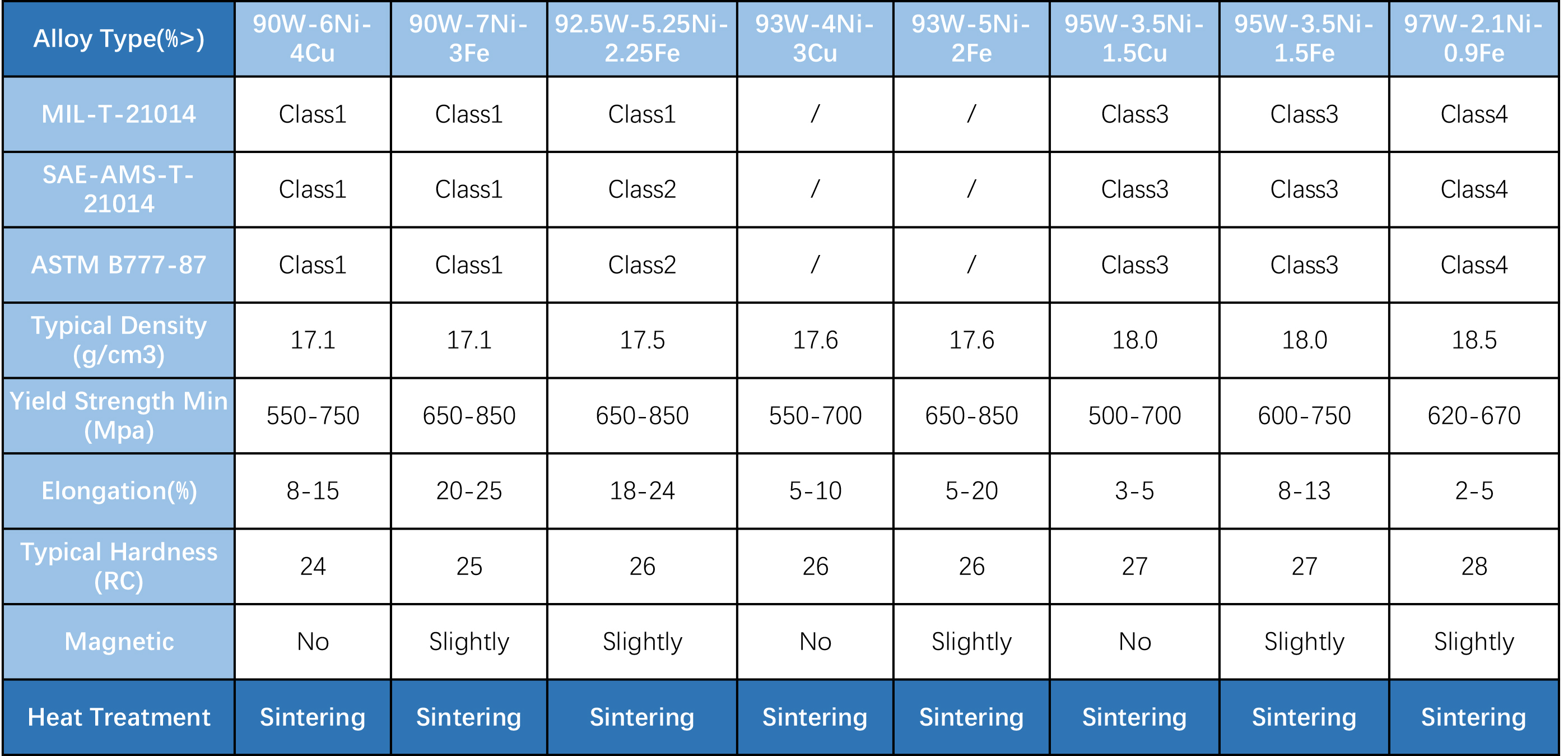

High-density tungsten round rods are made from a powder metallurgy process using tungsten (W) as the primary phase, with additional metals such as nickel (Ni), iron (Fe), or copper (Cu) added. These rods are manufactured through solid-phase/liquid-phase sintering. Compared to lead or ordinary steel, these high-density tungsten round rods offer higher density, better wear resistance, and greater mechanical strength. They are commonly used in counterweights, shielding, and high-end mechanical parts.

Tungsten alloy rods application

1. Counter weight

2. Radiation shield

3. Military industry

4. Dart rods

5. Welding rods

6. Mould etc

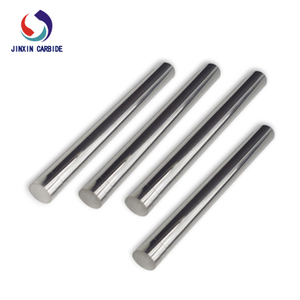

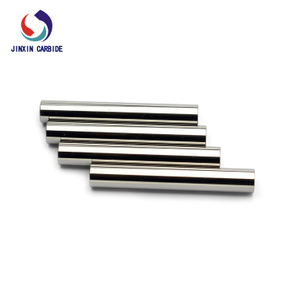

Specifications

| Diameter: | 3.0-100.0mm |

| Length: | 50-1000mm |

| Density: | 15.8-18.75g/cm3 |

| Composition: | W content: 85-99%, W-Ni-Fe, W-Ni-Cu |

| Application: | Tungsten alloy rods are used for the counterweight, radiation shield, military industry, dart rods, welding rods, mould etc. |

+86-18073319589

+86-18073319589