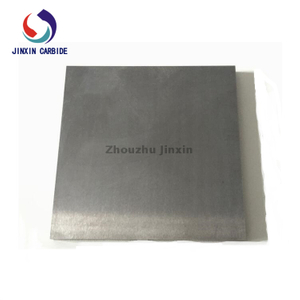

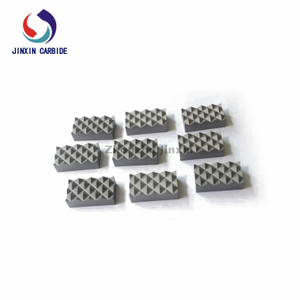

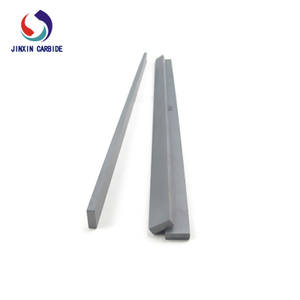

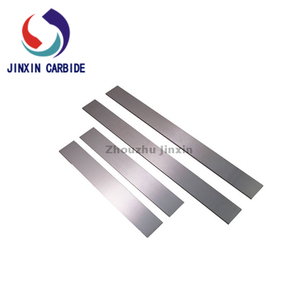

YG6 YG8 Tungsten Carbide Plate

Tungsten carbide plates/sheets/flat stocks are widely used in molding, woodworking, recycling, and chemical industries where excellent wear, corrosion, or high-temperature resistance is required. They are made from tungsten carbide, which is harder than many materials in terms of corrosion resistance and wear resistance. All our carbide plates have been stress-relieving HIP sintered in order to gain resistance to corrosion, pitting and cracking commonly experienced during machining.

Features

Cemented carbide sheet has excellent warp hardness, high hardness, good wear resistance, high modulus of elasticity, high compressive strength, good chemical stability (resistance to acids, alkalis, high temperature oxidation), lowimpact toughness, low coefficient of expansion, thermal and electrical conductivity similar to that of iron and its alloys. Silicon steel sheet, cold rolled sheet, suitable for making drawing dies, wear resistant parts and die cores for stamping accessories and carbide automatic presses, etc., using good strength and impact toughness, lower wear resistance than the above alloys. Top forging dies for large loads, such as those used for screws, rivets, etc., also for stamping dies. Extrusion dies. Punching and cutting dies etc.

Specifications

-

Grade,Performance & application recommended

Request for quotation and our sales team and engineers will work together to provide the most cost-efficient solution for you.

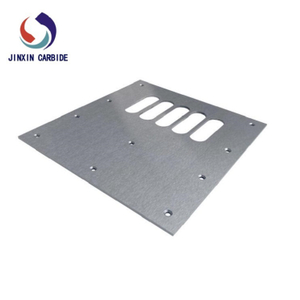

Used to make blanking dies. Used to make high-speed punching dies and multi-station progressive dies for punching and cutting copper, aluminum, stainless steel, cold rolled sheet, EI sheet, silicon steel sheet, hardware, standard parts, upper and lower punches and other thin sheets.

Used to make wear-resistant tools. Such as tools for woodworking industry, plastic crushing tools, etc.

Used to make high temperature resistant parts, wear resistant parts, and anti-shielding parts. Such as the guide rails of machine tools, anti-theft reinforcement plates of automatic teller machines, etc.

Used to make corrosion-resistant parts for the chemical industry.

Used for radiation and corrosion resistant materials for medical equipment. The performance of different grades of cemented carbide is not the same, and the use should be specifically based on the use of the appropriate material to choose the grade of cemented carbide.

+86-18073319589

+86-18073319589