Polycrystalline silicon crusher tungsten carbide jaw plate

Purpose:tungsten carbide jaw plate is mainly used for crushing polycrystalline silicon crusher.

Product features: hard alloy material high hardness, high wear resistance, long life, high purity, no pollution to the product, scientific design, easy installation and disassembly.

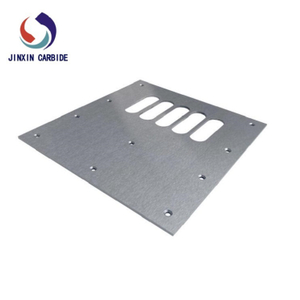

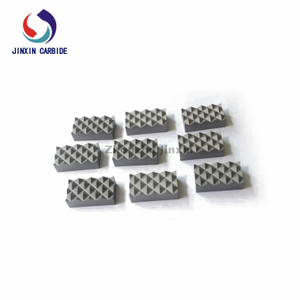

It is used in the jaw crusher, where it is divided into a fixed and movable plate. This plate is an important wear-resistant component of the jaw crusher.

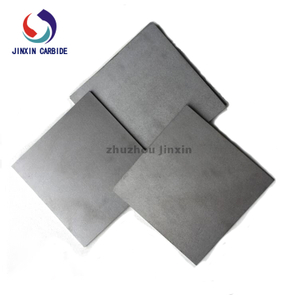

It exhibits a wear resistance that is 8 to 10 times more than chrome steel and manganese steel. Its primary function is to crush raw materials such as ore and polysilicon.

The carbide jaw plate (wear plater)has a significantly longer lifespan than competing materials, requiring minimal maintenance. This helps maintain the raw material's purity at a high level.

Jaw crusher jaw plate products: Jaw crusher is the leader of the crusher industry, is an international general crushing equipment, the mainstream jaw crusher models are: PE400×600 jaw crusher, PE500×750 jaw crusher, PE600×900 jaw crusher (also called 69 broken), PE900×1200 jaw crusher, etc., very widely used!

Jaw plate and side guard plate: Both the fixed jaw and the moving jaw consist of a jaw bed and a jaw plate. The jaw plate is the working part and is fixed to the jaw bed with bolts and wedge iron. The jaw bed is the front wall of the frame, and the movable jaw bed is hung on the circumference. It should have enough strength and stiffness to withstand the crushing force, so it is mostly cast steel or cast iron.

+86-18073319589

+86-18073319589