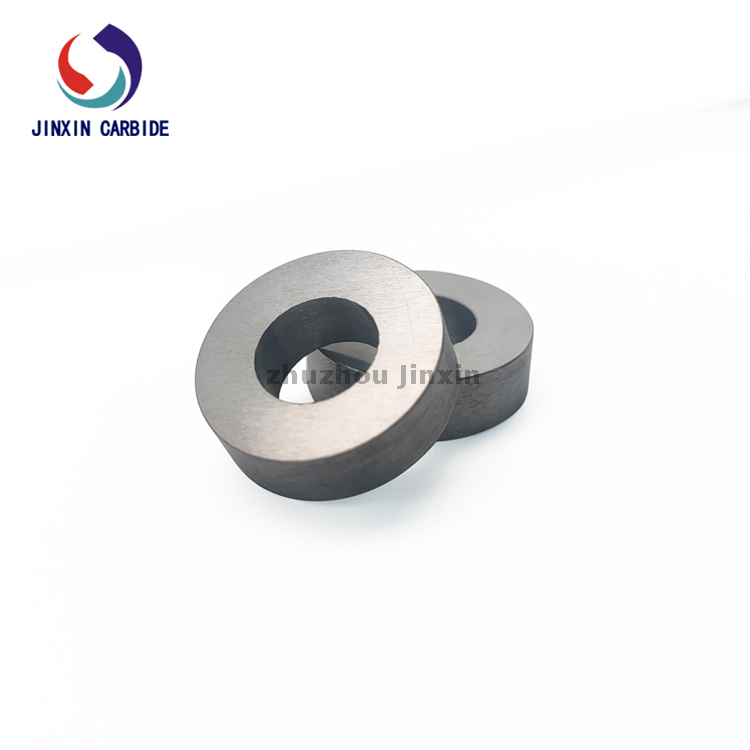

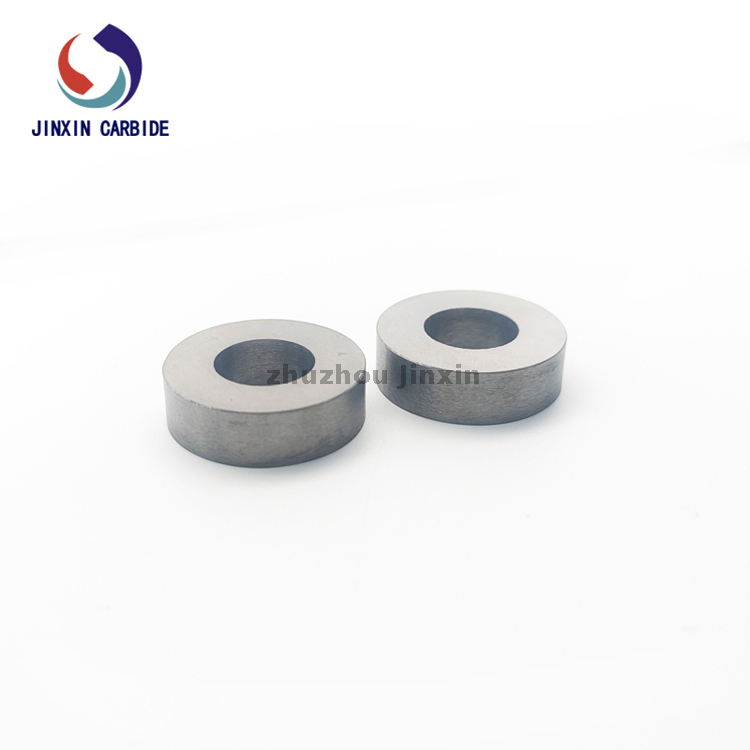

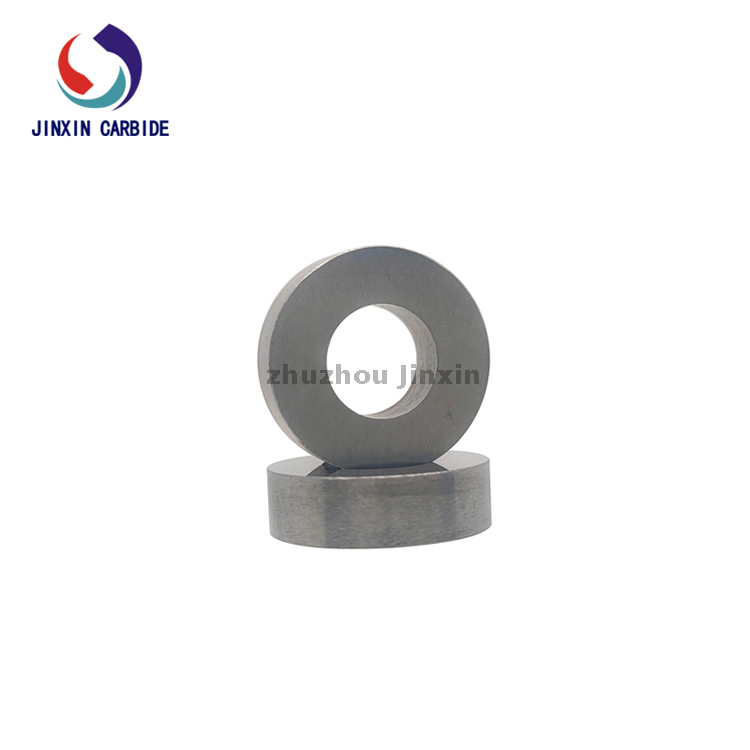

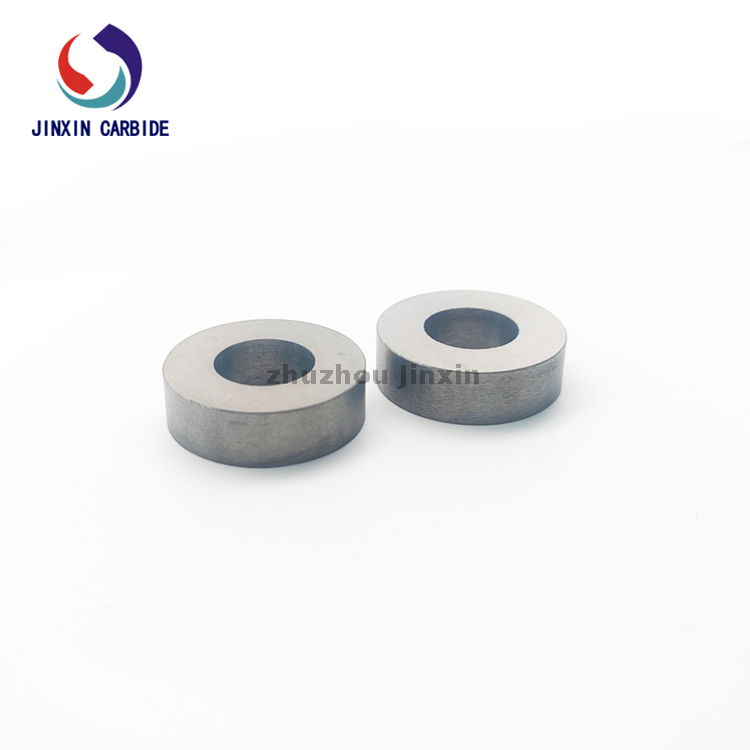

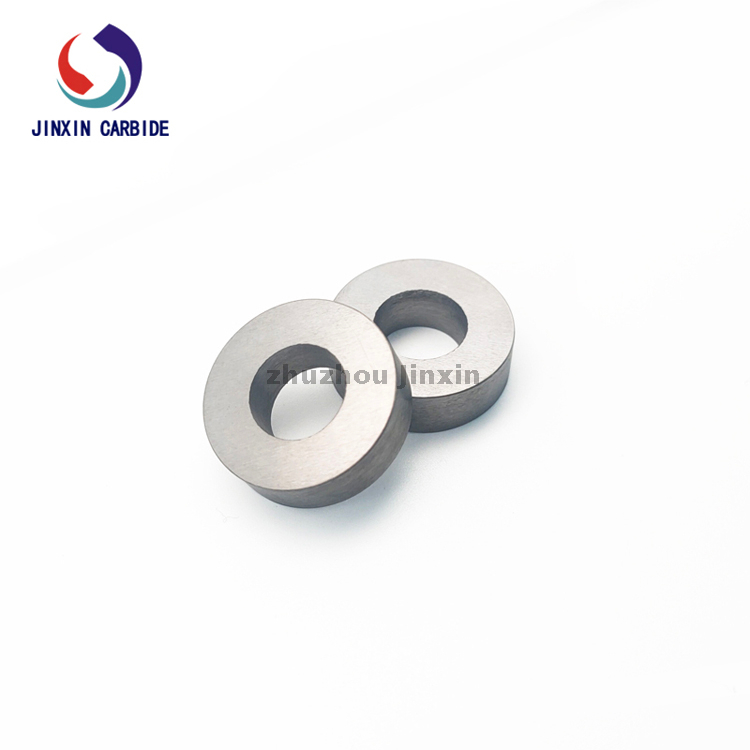

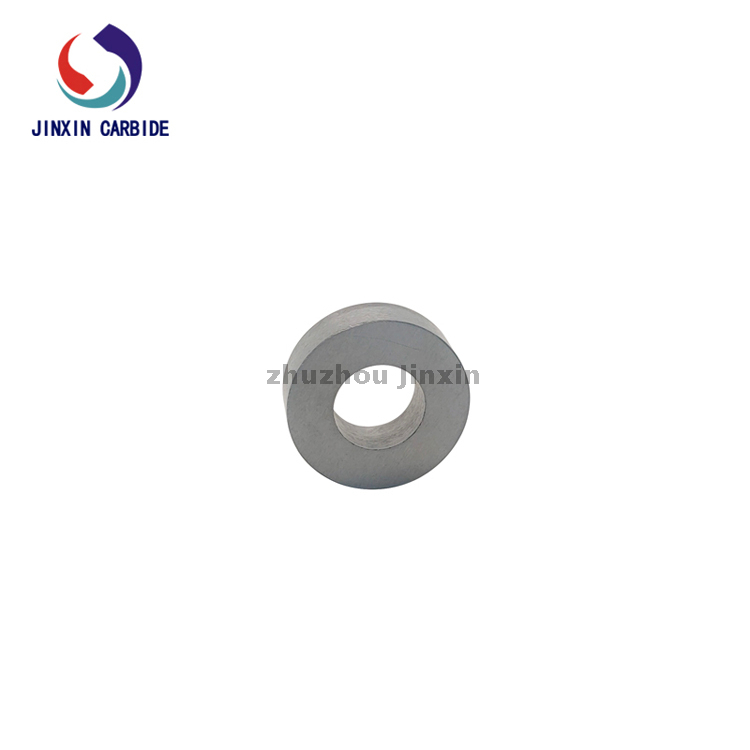

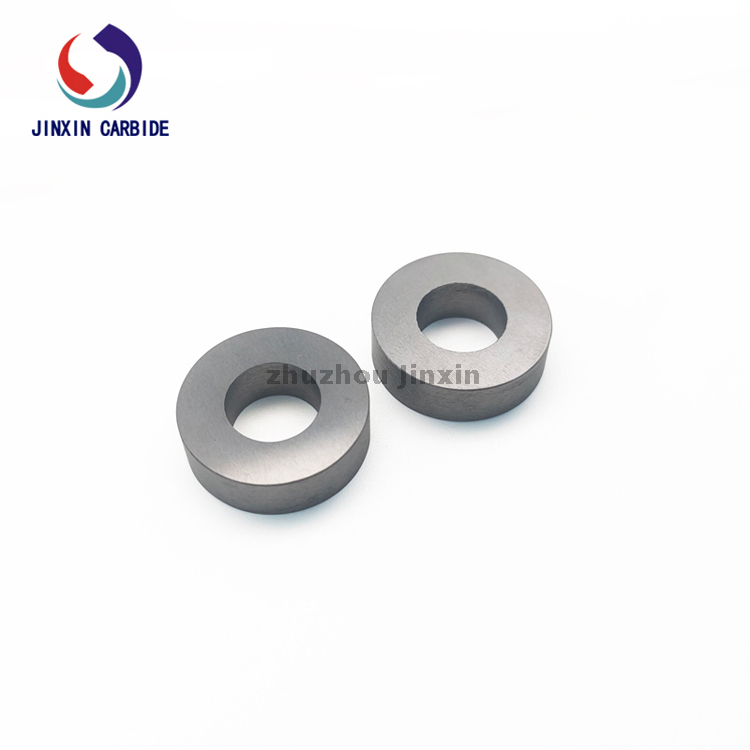

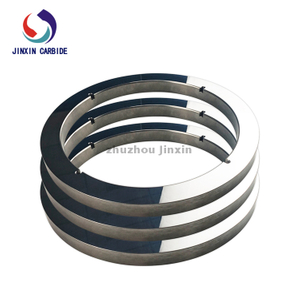

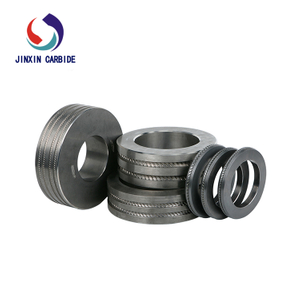

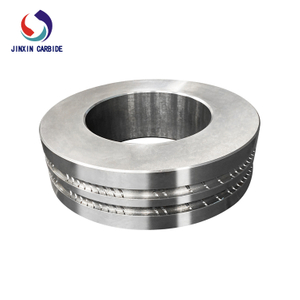

Cemented carbide bushing

The tungsten carbide bushing adopts CNC precision angles, inner hole grinder, precision surface grinding machine, precision internal and external round grinder, centerless grinder. The inner hole is grinded many times and polished into a mirror.

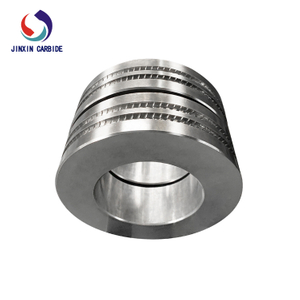

Cemented carbide bushing application

The carbide bushing has excellent chemical stability, which is widely applied in the industries of petrochemicals, submersible oil pumps, slurry pumps, water pumps, centrifugal pumps. With the increase in oil production, the shallow surface of the oil is reduced, In order to ensure oil usage, people have gradually developed to extract from the large deep well, but the difficulty of mining gradually increases and the mining components have high requirements for wear resistance, corrosion resistance or impact resistance.

| Name | Tungsten carbide sleeves & bushings |

|---|

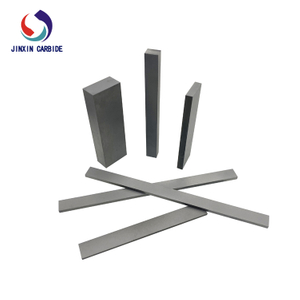

| Material | Tungsten carbide, hard metal, hard alloy,tungsten steel |

| Composition | Tungsten carbide – TC: 93.8%, Nickle 6.0%, Other: 0.2% |

| Density | 14.8g/cm3 |

| Hardness | HRA91.5 |

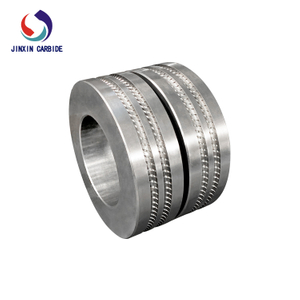

| Features,advantages | Wear resistant, corrosion resistant, impact resistant |

| Size ranges | OD/10~500, ID/3~450, H/8~300 |

| Finish | As Sintered or Ground |

| OEM Service | Customized design & size available |

| Applications(Equipment) | For water pump ,oil pump,slurry pump ,heavy duty pump and other flow control part |

| Applications(Use for ) | Wear- and corrosion resistant cemented carbide is used as a sleeve of vertical mixed flow pump bearing used in a power plant and chemical plants |

+86-18073319589

+86-18073319589