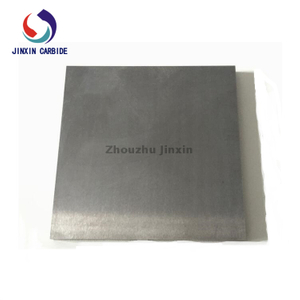

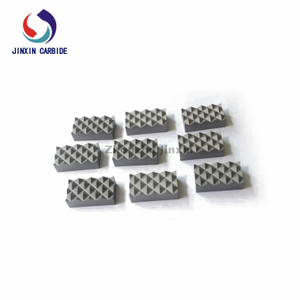

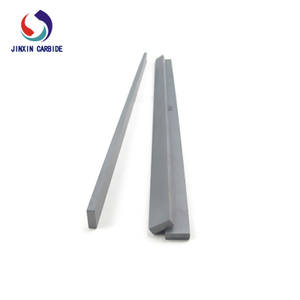

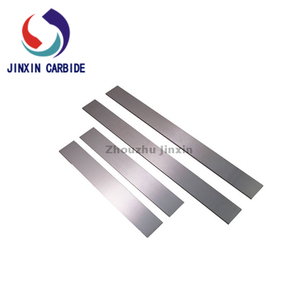

100mm 200mm 300mm Solid Tungsten Carbide Strips

Tunsgten carbide strips is mainly made of WC (tungsten carbide) and Co (cobalt )mixed by metallurgical method through powder making, ball milling, pressing and sintering, the main alloy composition is WC and Co, the composition content of WC and Co in cemented carbide strips for different applications is not the same, the use range is extremely wide.

Jinxin Carbide Plates Features

100% virgin WC powder;

Outstanding wear, impact, corrosion, and high-temperature resistance;

Excellent chemical stability (acid, alkali, oxidation resistance);

Varied grades and specifications;

Ground and unground;

High and consistent quality;

Customization services.

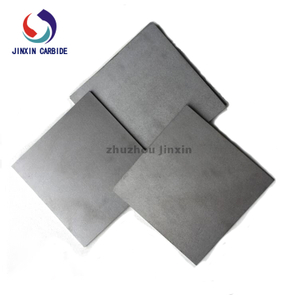

Specifications

Grade,Performance & application recommended

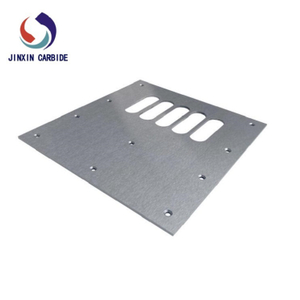

Used to make blanking dies. Used to make high-speed punching dies and multi-station progressive dies for punching and cutting copper, aluminum, stainless steel, cold rolled sheet, EI sheet, silicon steel sheet, hardware, standard parts, upper and lower punches and other thin sheets

Used to make wear-resistant tools. Such as tools for woodworking industry, plastic crushing tools, etc.

Used to make high temperature resistant parts, wear resistant parts, and anti-shielding parts. Such as the guide rails of machine tools, anti-theft reinforcement plates of automatic teller machines, etc.

Used to make corrosion-resistant parts for the chemical industry.

Used for radiation and corrosion resistant materials for medical equipment. The performance of different grades of cemented carbide is not the same, and the use should be specifically based on the use of the appropriate material to choose the grade of cemented carbide.

Request for quotation and our sales team and engineers will work together to provide the most cost-efficient solution for you.

+86-18073319589

+86-18073319589