In the world of modern manufacturing, construction, and industrial processing, tools need to be stronger, sharper, and longer-lasting than ever before. One material that has stood out in recent decades for delivering exceptional durability and cutting power is Tungsten Carbide. Among its many applications, Tungsten Carbide bits are some of the most widely used components across industries. These high-performance tools are essential for drilling, cutting, and shaping tough materials such as metal, wood, masonry, and plastic.

This article explores in-depth what a Tungsten Carbide bit is, how it works, its material composition, the advantages it offers, and the wide variety of related Tungsten Carbide tools on the market today.

Understanding Tungsten Carbide

Tungsten Carbide is a compound made from equal parts of tungsten and carbon atoms. It is known for its extreme hardness and durability, ranking close to diamonds on the Mohs scale of hardness. In most applications, Tungsten Carbide is mixed with a binder metal such as cobalt to form a dense, tough composite material. This composite is what makes Tungsten Carbide the material of choice for high-performance cutting tools.

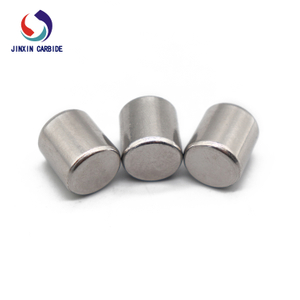

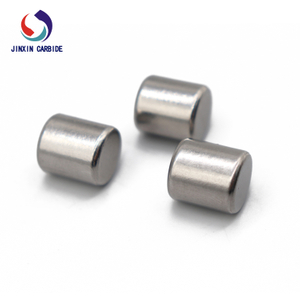

What Are Tungsten Carbide Bits

Tungsten Carbide bits are specialized cutting tools used in a variety of industries to drill, bore, mill, and shape hard materials. These bits can withstand high levels of heat, friction, and pressure without losing their edge, which makes them ideal for both precision and heavy-duty applications.

Unlike conventional steel or high-speed steel (HSS) bits, Tungsten Carbide bits retain their sharpness longer and require less frequent replacement. This makes them highly cost-effective for continuous industrial use.

Material Composition of Tungsten Carbide Bits

| Component | Percentage (%) | Purpose |

|---|

| Tungsten | 70–97 | Provides hardness and wear resistance |

| Carbon | 3–10 | Combines with tungsten for hardness |

| Cobalt (Binder) | 3–25 | Offers toughness and binding strength |

This optimized composition allows Tungsten Carbide tools to perform exceptionally well under high-stress conditions.

Applications of Tungsten Carbide Bits

Tungsten Carbide bits are used in various industries including:

Manufacturing: Cutting and drilling through metals like steel, aluminum, and titanium

Construction: Penetrating concrete, masonry, and stone

Woodworking: Carving, shaping, and detailing of hardwoods

Plastics: Smooth, precise cuts through synthetic materials

Their ability to maintain sharpness and resist wear under high-temperature and high-pressure conditions makes them irreplaceable in demanding environments.

Types of Tungsten Carbide Tools

Understanding the full ecosystem of Tungsten Carbide tools gives insight into its versatility. Below is a breakdown of the most common tools and their applications:

| Tool Name | Description & Application |

| Tungsten Carbide Rotary Burrs | Used for metal shaping, grinding, and deburring in automotive and aerospace industries |

| Tungsten Carbide Ball | Used in precision instruments, valves, and bearings |

| Tungsten Carbide Rods | Raw material for end mills, drills, and reamers |

| Tungsten Carbide Plate & Strip | Ideal for cutting tools, molds, and wear-resistant surfaces |

| Tungsten Carbide Ring | Employed in seals and mechanical wear applications |

| Tungsten Carbide Cutting Tools | Encompasses a wide range of turning, milling, and drilling tools |

| Tungsten Carbide Roller | Used in metal forming and rolling applications |

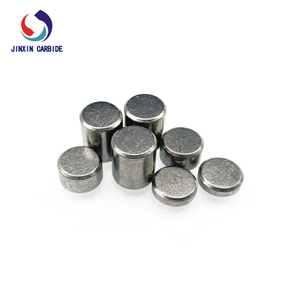

| Tungsten Carbide Studs | High wear resistance in tire studs and crushing rollers |

| Tungsten Carbide Mould | Used in metal stamping, extrusion, and forming processes |

| Tungsten Carbide Tip | Commonly brazed onto tools like saw blades and drill bits for extended life |

| Tungsten Carbide Wear Parts | Applied in areas with high friction and wear, such as mining and oil drilling tools |

4 Advantages of Using Tungsten Carbide Drill Bits

1. Exceptional Durability

Tungsten Carbide drill bits outperform other materials when it comes to longevity. Their resistance to wear, abrasion, and deformation ensures consistent performance over extended periods.

2. High-Temperature Resistance

Drilling through hard metals and masonry generates a significant amount of heat. Thanks to their high melting point, Tungsten Carbide bits maintain structural integrity and sharpness even at extreme temperatures.

3. Versatility Across Materials

From Tungsten Carbide Plate & Strip to Tungsten Carbide Mould, the adaptability of this material allows its use across a range of tools and applications. This includes metals, woods, plastics, and stone.

4. Precision Cutting Capability

Tungsten Carbide Cutting Tools offer fine, clean cuts with minimal burring or splintering. This makes them ideal for applications requiring high tolerances and fine detail, such as in die-making or CNC machining.

Latest Trends in Tungsten Carbide Applications

As industries continue to evolve, so does the demand for more advanced tools. Recent innovations include:

Nano-coating of Tungsten Carbide bits to reduce friction and further enhance longevity.

The integration of Tungsten Carbide Wear Parts into additive manufacturing equipment.

Use of Tungsten Carbide Rods in aerospace component fabrication.

Increased demand for Tungsten Carbide Roller systems in sustainable energy applications, such as wind turbine component manufacturing.

Comparison: Tungsten Carbide vs. High-Speed Steel (HSS)

| Feature | Tungsten Carbide | High-Speed Steel (HSS) |

| Hardness | Very High | Moderate |

| Heat Resistance | Excellent | Good |

| Durability | Long-lasting | Wears faster |

| Cost | Higher initial cost | Lower upfront cost |

| Best For | Heavy-duty and high-precision work | General purpose and softer materials |

The data clearly supports the growing preference for Tungsten Carbide over traditional materials in high-performance applications.

Maintenance Tips for Tungsten Carbide Bits

To maximize the life of your Tungsten Carbide bits, follow these best practices:

Always use appropriate speeds and feeds based on material type.

Apply adequate cooling to reduce thermal stress.

Use the right bit shape and size for the task.

Clean the bits regularly to prevent residue build-up.

Proper maintenance ensures that Tungsten Carbide Cutting Tools, Rotary Burrs, and Tips deliver peak performance over time.

Conclusion

Tungsten Carbide has revolutionized the world of industrial tooling. From Tungsten Carbide Rotary Burrs for precision shaping to Tungsten Carbide Tips for power drilling, the material's unmatched hardness, heat resistance, and versatility make it a go-to choice for professionals worldwide. Whether you're in manufacturing, construction, or any application requiring durable and precise tools, Tungsten Carbide provides a dependable, high-performance solution.

With ongoing innovations and a growing range of applications—from Tungsten Carbide Studs to Wear Parts—it’s clear that this advanced material will continue to shape the future of tooling and industrial efficiency. If your goal is to improve output, reduce downtime, and gain cutting-edge precision, investing in Tungsten Carbide tools is a smart and forward-thinking decision.

+86-18073319589

+86-18073319589