Views: 0 Author: Site Editor Publish Time: 2024-08-23 Origin: Site

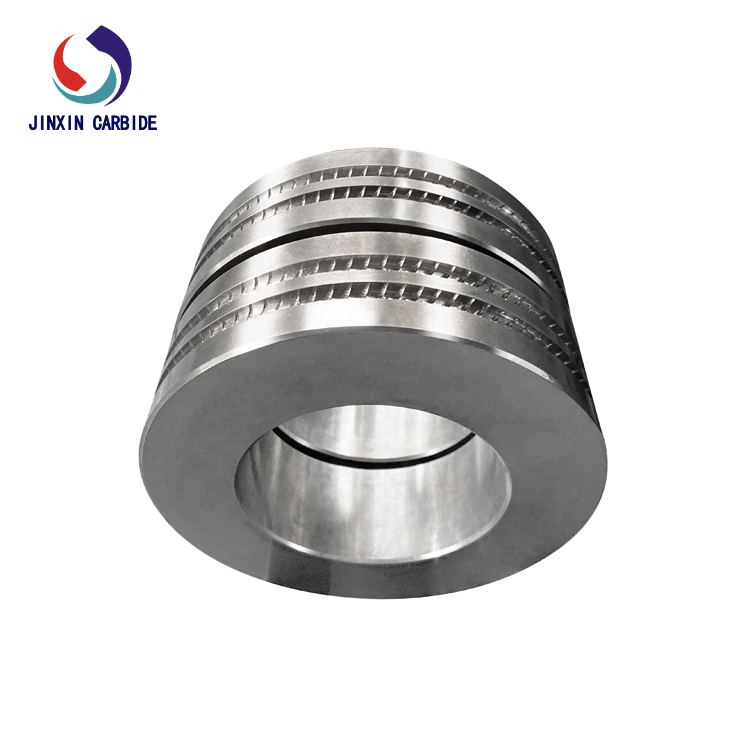

Tungsten carbide roll rings are high-performance components specially designed for metal rolling processes to cover the surface portion of rolls, and are mainly composed of a hard phase (tungsten carbide WC) and a metal-bonded phase (usually metallic cobalt and nickel), as well as trace amounts of rare metal elements. Its performance is determined by the content of the bonding metal and the size of the tungsten carbide particles.

Tungsten carbide roll ring has a series of excellent properties such as high hardness, high wear resistance, high temperature red hardness, heat fatigue resistance and high strength. Its hardness value with the temperature change is very small, 700 ℃ when the hardness value of high-speed steel 4 times; and the modulus of elasticity, compressive strength, flexural strength, thermal conductivity are higher than tool steel more than 1 times.

According to the structural form, it can be divided into two kinds: integral tungsten carbide roll ring and composite tungsten carbide roll ring:

Integral tungsten carbide roll ring: has been widely used in high speed wire rod mill pre-finishing and finishing mill stand (including fixed reduction stand, pinch roll stand) and so on.Composite tungsten carbide roll ring: made of tungsten carbide and other materials composite, can be divided into tungsten carbide composite roll ring and the whole tungsten carbide composite roll. The composite roll ring is installed on the roll shaft; the overall carbide composite roll will be cast directly in the carbide roll ring in the roll shaft to form a whole, applied to rolling load on the larger mill.

content is empty!