Views: 0 Author: Site Editor Publish Time: 2024-08-09 Origin: Site

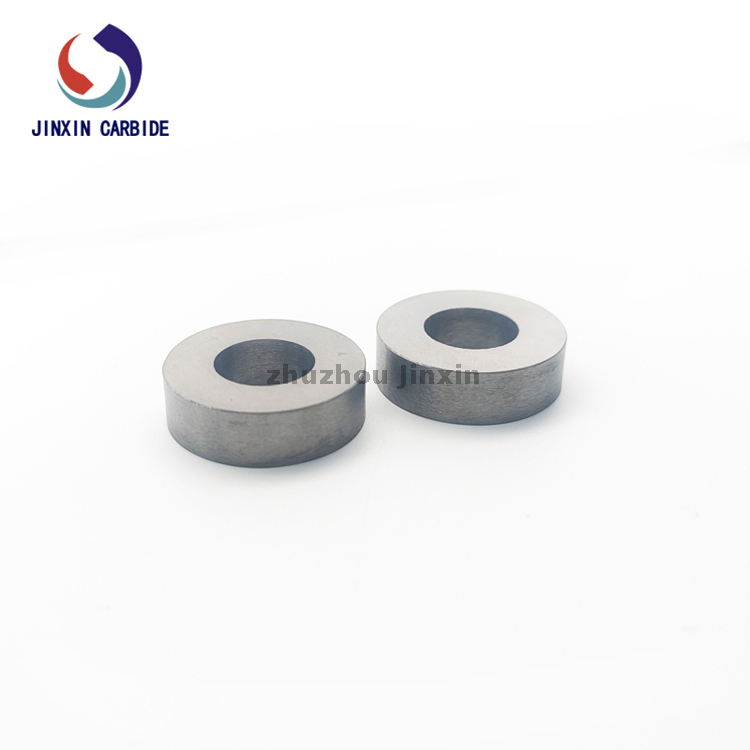

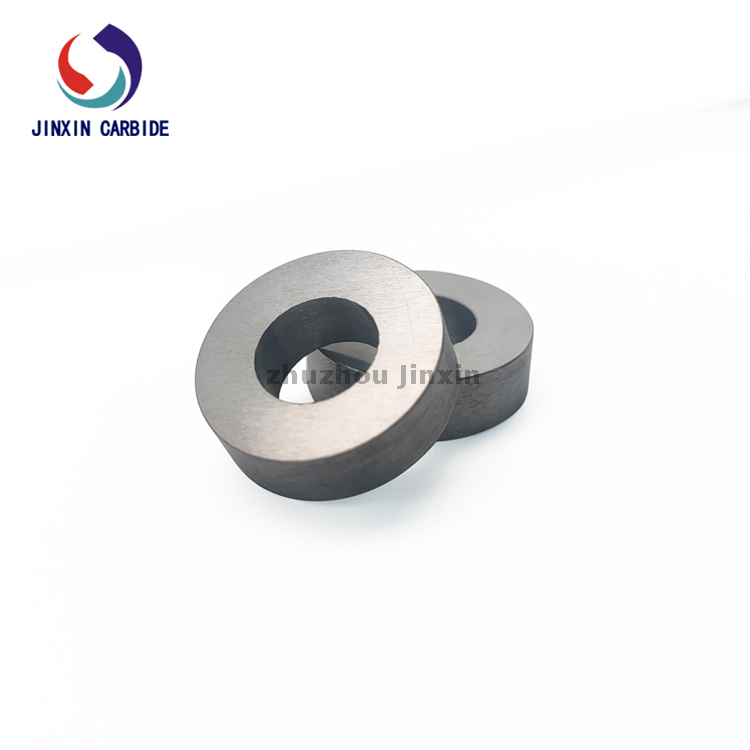

The production process of tungsten carbide rings includes the steps of raw material preparation, mixing of raw materials, press molding, sintering, cooling and deburring, polishing and finishing. Tungsten carbide is a very hard material, which is produced by the reaction between tungsten and carbon at high temperature. The specific step contents are as follows:

1. Raw material preparation: The raw material needs to be prepared tungsten powder and carbon powder. Tungsten powder is usually extracted from tungsten ore, and carbon powder can be graphite or other forms of carbon.

2. Mixing of raw materials: Tungsten powder and carbon powder are mixed in a certain proportion. This mixture is usually mixed in a ball mill to ensure homogeneity.

3. Pressing and forming: The mixed powder is placed in a mold and pressed into a ring shape using high pressure. This step is usually done in a cold press and the pressing pressure is very high to ensure that the powder forms a solid shape in the mold.

4. Sintering: The pressed tungsten carbide rings are sintered in a sintering furnace. At high temperatures (usually around 2000°C), the tungsten and carbon powders react to form tungsten carbide. This process makes the tungsten carbide rings extremely hard and wear-resistant. The temperature and time of sintering need to be precisely controlled to ensure the quality of the final product.

5. Cooling and deburring: The sintered tungsten carbide needs to be cooled slowly. After cooling, the ring may have some burrs and irregular edges, which need to be ground and polished to obtain a smooth surface.

6. Polishing and Finishing: Tungsten carbide rings are polished to achieve the desired gloss and appearance. This step may include hand polishing and the use of various polishing tools.

content is empty!