When it comes to durable and resilient materials, tungsten and its compound tungsten carbide often come to mind. Known for their exceptional hardness and resistance to wear, these materials are widely used in jewelry, tools, and industrial applications. A frequent question among users is: Does tungsten metal rust? The simple answer is that pure tungsten does not rust, thanks to its inherent properties, while tungsten carbide offers excellent corrosion resistance but isn’t entirely immune under specific conditions. This comprehensive article explores the rust resistance of tungsten metal and tungsten carbide, comparing them to steel and delving into factors that might cause degradation. We’ll also examine related products like tungsten carbide rings, tungsten carbide rods, and tungsten carbide rotary burrs, providing data-driven insights.

What Is Tungsten Metal and Tungsten Carbide?

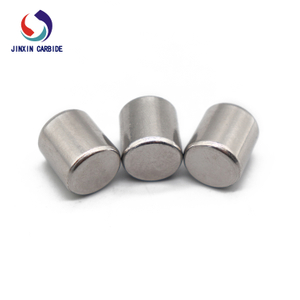

Tungsten is a heavy, dense metal with the atomic number 74, prized for its high melting point and durability. In its pure form, tungsten resists rust and tarnish, making it a popular choice for applications where longevity is key. Tungsten carbide, on the other hand, is a compound formed by combining tungsten with carbon atoms, typically cemented together with a binder like cobalt or nickel. This creates a material far harder than pure tungsten, ranking 9 to 9.5 on the Mohs scale, and widely used in tools and wear-resistant parts.

While pure tungsten is a single element, tungsten carbide is a composite, and its rust resistance depends on both the tungsten carbide grains and the binder. Products like tungsten carbide balls and tungsten carbide plates & strips leverage this compound’s properties, but their performance against rust and corrosion varies based on composition and environment.

Does Pure Tungsten Metal Rust?

Rust is the common term for iron oxide, formed when iron reacts with oxygen and moisture. Since pure tungsten contains no iron, it doesn’t rust in the traditional sense. Instead, tungsten forms a thin oxide layer—tungsten trioxide (WO₃)—when exposed to air. This layer is stable and protective, preventing further degradation under normal conditions. Unlike iron’s flaky rust, tungsten’s oxide adheres tightly to the surface, preserving its integrity.

Pure tungsten’s rust resistance makes it ideal for applications like tungsten carbide rings, where the base metal’s properties contribute to a polished, long-lasting finish. However, pure tungsten is rarely used alone in tools due to its brittleness, which is why tungsten carbide dominates in industrial contexts.

Does Tungsten Carbide Rust?

Tungsten carbide itself doesn’t rust because it lacks iron. The tungsten carbide grains—made of tungsten and carbon—are highly inert and resistant to oxidation. However, the binder material, typically cobalt or nickel, introduces nuances to its corrosion resistance. Here’s how tungsten carbide behaves:

Cobalt Binder: Most tungsten carbide uses cobalt (6-20% by weight) as a binder. Cobalt is corrosion-resistant but can degrade in acidic environments, leading to a process called leaching. This dissolves the cobalt matrix, leaving the tungsten carbide grains unsupported and prone to crumbling.

Nickel Binder: For enhanced corrosion resistance, some tungsten carbide uses nickel, which outperforms cobalt in harsh conditions like acidic or saline environments. This makes nickel-bound tungsten carbide a preferred choice for applications requiring superior durability.

While tungsten carbide won’t rust like steel, its binder can corrode under specific circumstances, affecting its structural integrity rather than its appearance.

Comparing Tungsten Carbide Pliers to Steel

Pliers made from tungsten carbide and steel offer a compelling comparison in terms of corrosion resistance. Steel, especially carbon steel, contains iron and is highly susceptible to rust when exposed to moisture and oxygen. Stainless steel improves on this with added chromium, forming a passive oxide layer, but it can still pit or corrode in salty or acidic conditions.

Tungsten carbide pliers, often featuring tungsten carbide tips, don’t rust due to the absence of iron. Their corrosion resistance surpasses steel, particularly when nickel is the binder. However, cobalt-bound tungsten carbide pliers can suffer leaching in acidic environments, as seen in orthodontic tools exposed to disinfectants like glutaraldehyde. Steel pliers, meanwhile, rust readily without protective coatings or alloys.

| Material | Rust Resistance | Corrosion Resistance | Common Binder/Metal | Typical Use |

|---|

| Tungsten Carbide | Excellent | Good (Cobalt) to Excellent (Nickel) | Cobalt, Nickel | Pliers, tools, jewelry |

| Carbon Steel | Poor | Poor | Iron | Basic tools |

| Stainless Steel | Good | Good | Iron, Chromium | Cutlery, surgical tools |

Tungsten carbide pliers outshine steel in rust resistance and generally in corrosion resistance, especially with nickel binders, making them ideal for demanding environments.

Factors That Can Cause Rust or Corrosion

While pure tungsten and tungsten carbide resist rust, certain conditions can lead to degradation:

Alloying Elements

Tungsten alloys, unlike pure tungsten or tungsten carbide, may include metals prone to rusting, such as iron. For example, a tungsten alloy with iron impurities could oxidize when exposed to moisture. In tungsten carbide, the binder’s susceptibility (e.g., cobalt vs. nickel) determines corrosion risk.

Environmental Conditions

Moisture and oxygen are rust’s primary drivers, but they don’t affect pure tungsten or tungsten carbide significantly. However, prolonged exposure to humid, salty environments can corrode cobalt binders in tungsten carbide rods or tungsten carbide rotary burrs, though nickel-bound versions resist better.

Extreme Heat

Pure tungsten remains rust-free at typical temperatures but oxidizes above 600°C, forming a thicker oxide layer. Tungsten carbide is less affected by heat, though binders may degrade under extreme conditions, impacting tools like tungsten carbide plates & strips.

Presence of Iron

If tungsten carbide or tungsten contains iron impurities—rare in high-quality products—rust becomes possible. This is more a concern with low-grade alloys than standard tungsten carbide items like tungsten carbide balls.

Rust Resistance in Tungsten Carbide Products

Tungsten carbide’s rust resistance shines across its various forms:

Tungsten Carbide Rotary Burrs

Tungsten carbide rotary burrs, used for grinding and shaping, resist rust due to their iron-free composition. Nickel-bound versions excel in corrosive environments like marine workshops, while cobalt-bound burrs may need care around acids.

Tungsten Carbide Ball

Tungsten carbide balls, found in bearings and valves, maintain their integrity without rusting. Their smooth surface, protected by the tungsten carbide matrix, withstands moisture and friction effortlessly.

Tungsten Carbide Rods

Tungsten carbide rods, raw material for cutting tools, don’t rust but can corrode if cobalt leaches in acidic conditions. Nickel-bound rods are favored for rust-free longevity in humid settings.

Tungsten Carbide Plate & Strip

Tungsten carbide plates & strips, used in wear-resistant applications, resist rust and corrosion well, especially with nickel binders, making them ideal for mining or chemical processing.

Tungsten Carbide Ring

Tungsten carbide rings are a jewelry standout, resisting rust and tarnish under normal wear. High-quality rings with nickel binders avoid even minor corrosion, unlike alloys with iron impurities.

Practical Tips to Prevent Corrosion

To maximize tungsten carbide’s rust resistance:

Choose Nickel Binders: Opt for nickel-bound tungsten carbide rings or tungsten carbide rods for superior corrosion resistance.

Avoid Acids: Keep tungsten carbide rotary burrs and pliers away from acidic cleaners or disinfectants to prevent leaching.

Clean Properly: Use mild soap and water on tungsten carbide balls or tungsten carbide plates & strips, avoiding harsh chemicals.

Inspect Alloys: Ensure tungsten carbide products lack iron impurities, especially in budget items.

Trends in Tungsten Carbide Rust Resistance

Tungsten carbide continues to evolve with innovations enhancing its rust and corrosion resistance:

Nickel Dominance: Nickel binders are increasingly popular in tungsten carbide rings and tools, reducing corrosion risks compared to cobalt.

Protective Coatings: Nano-coatings on tungsten carbide rotary burrs and tungsten carbide rods bolster resistance to acids and heat.

Sustainable Alloys: Recycled tungsten carbide maintains rust resistance while appealing to eco-conscious industries.

These advancements ensure tungsten carbide remains a top choice for rust-free applications.

Conclusion

Does tungsten metal rust? Pure tungsten does not, thanks to its lack of iron and stable oxide layer, while tungsten carbide offers excellent rust resistance but can corrode under specific conditions due to its binder. Compared to steel, tungsten carbide pliers and products like tungsten carbide rings, tungsten carbide balls, tungsten carbide rods, tungsten carbide plates & strips, and tungsten carbide rotary burrs excel in rust resistance, especially with nickel binders. Factors like alloying elements, environmental conditions, and heat can influence degradation, but proper care mitigates these risks. As technology advances, tungsten carbide’s rust resistance strengthens, solidifying its reputation as a durable, corrosion-resistant material.

+86-18073319589

+86-18073319589