| CUTTING TOOL MACHINING ASKED QUANTITY AND SOLUTION |

| Question | causes | solutions |

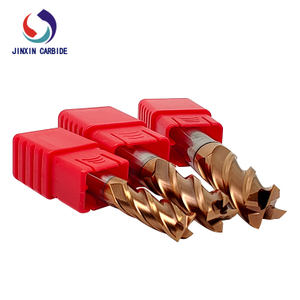

breakage

of the

milling cutter | If the feed speed is too fast,

the speed is too slow | Reduce the feed speed or increase the speed,

the normal speed of the engraving machine

should be more than 20000 rpm. |

Too much cutting

allowance | reduce the amount of cutting |

The tool extends too

long and the clamping part is too few | Minimize the protruding part as much as

possible to ensure that the

clamping part is more than 4 times the handle |

| The cutting edge is severely worn | Change the tool and regrind, or reduce the cutting speed |

| The fixture accuracy is too poor | replace the fixture |

| Spindle or fixture is loose | adjust the spindle or fixture |

The processing surface is complicated

and there are too many dead angles | Adjust cutting parameters, programming mode |

| The workpiece is not stable | improve the fixture to ensure

that the workpiece is stable |

Poor chip evacuation

and serious chip staining | Re-select the tool model and change the cooling method |

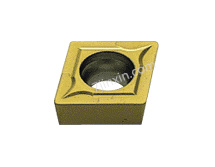

The blade is easy to crack-the feed

speed is too fast | The feed speed is too fast,

the cutting edge is too sharp or the tip angle is too sharp | Reduce the feed speed and chamfer

with a steel file to make the

cutting edge dull |

The accuracy of the chuck is too

poor or the installation is poor | Replace the chuck, or

clean up debris in the chuck |

The rigidity of the fixture is

too poor, and the grasping force is not enough. | Reduce cutting parameters |

The shape of the workpiece is

complicated, and there are too

many dead angles | Change low cutting parameters

and change method |

The installation of

the workpiece is unstable | Improve tooling and fixtures

to ensure that the workpiece is stable |

| The cutting direction is incorrect | Climbing milling is generally used |

There are impurities in the material

| Pay attention to material and cutting speed |

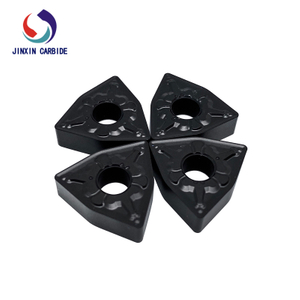

The blade

is easy to wear | The rotation speed is too

fast or the feed speed is too slow | Reduce the number of revolutions

or increase the feed rate |

The accuracy of the spindle or

fixture is not high | Adjust the spindle accuracy or

replace the fixture |

Poor chip evacuation and

sticky chips on the cutting edge | Choose the right tool model

to improve the chip removal method |

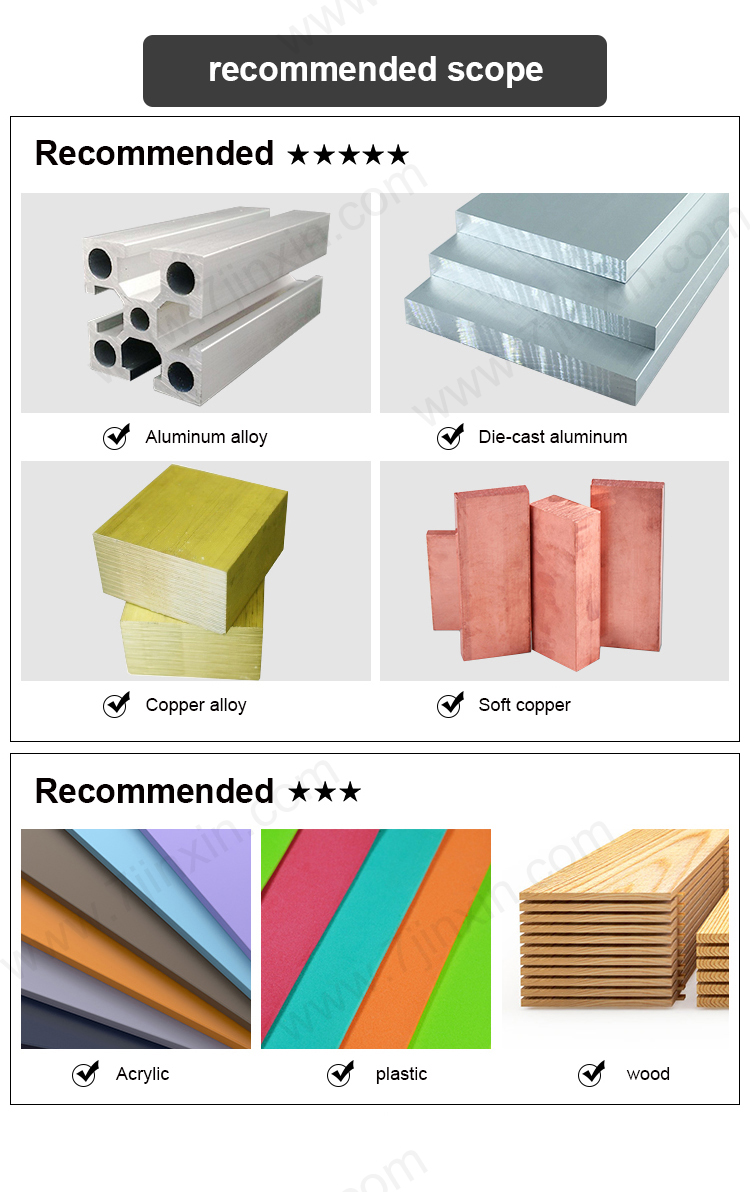

The workpiece material is unknown

and the tool model is incorrectly selected | Determine the material,

select the corresponding model |

| The cutting fluid is not selected correctly | choose the correct cutting fluid |

| The cutting direction is incorrect | choose the down milling method |

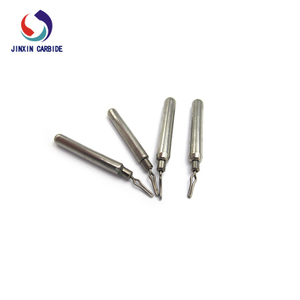

Poor

surface finish | The feed rate is too fast

or the speed is too slow | Low feed rate or increase speed |

| The tool wear is severe | Change tool |

The accuracy of the tool

is not high after grinding | New props are recommended for finishing |

| Excessive accumulation of cutting chips | Clear cutting chips and change the cooling method |

| There is no cutting cooling device | Use correct and necessary cooling devices (such as water cooling, etc.) |

| The tool vibrates greatly | Choose high-rigidity, high-precision, strong gripping fixtures, and minimize the tool extension length |

| Can not achieve the desired effect | It will be better to choose a tool with a larger diameter or a good engraving machine |

+86-18073319589

+86-18073319589