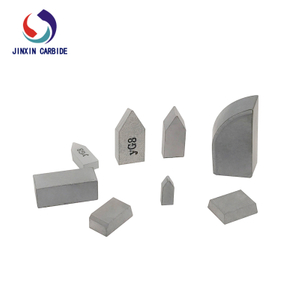

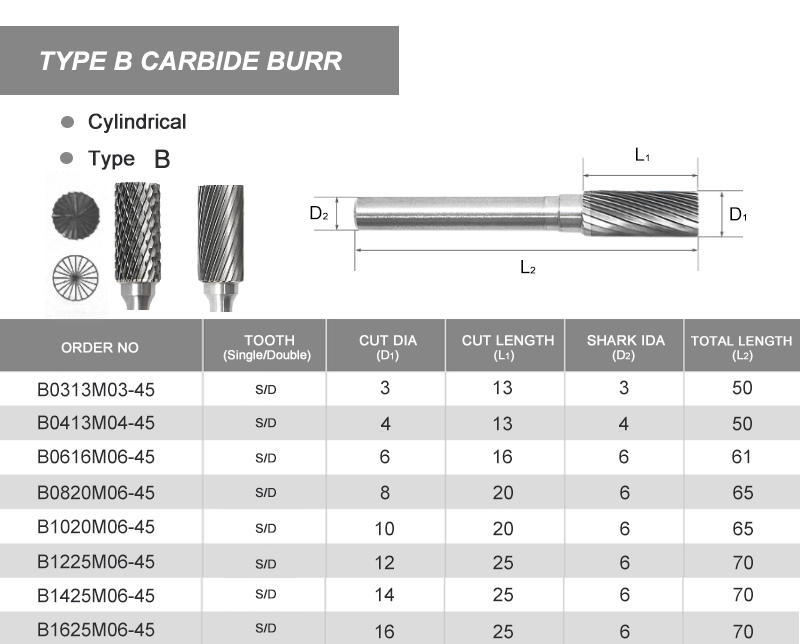

Type B carbide burr description

Type B rotary files are usually designed with cylindrical or spherical heads. Cylindrical Type B rotary files with cylindrical teeth can be used for machining flat surfaces, holes, grooves, etc. Spherical files are more suitable for machining and finishing curved surfaces, arcs and other shapes, and are able to fit the contours of the workpiece better to achieve finer cutting and grinding.

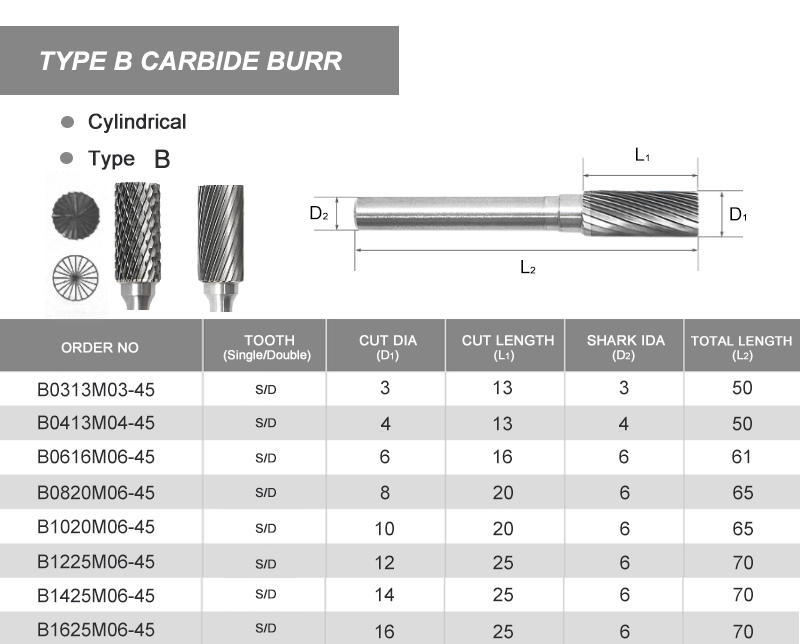

Type B carbide burr specification

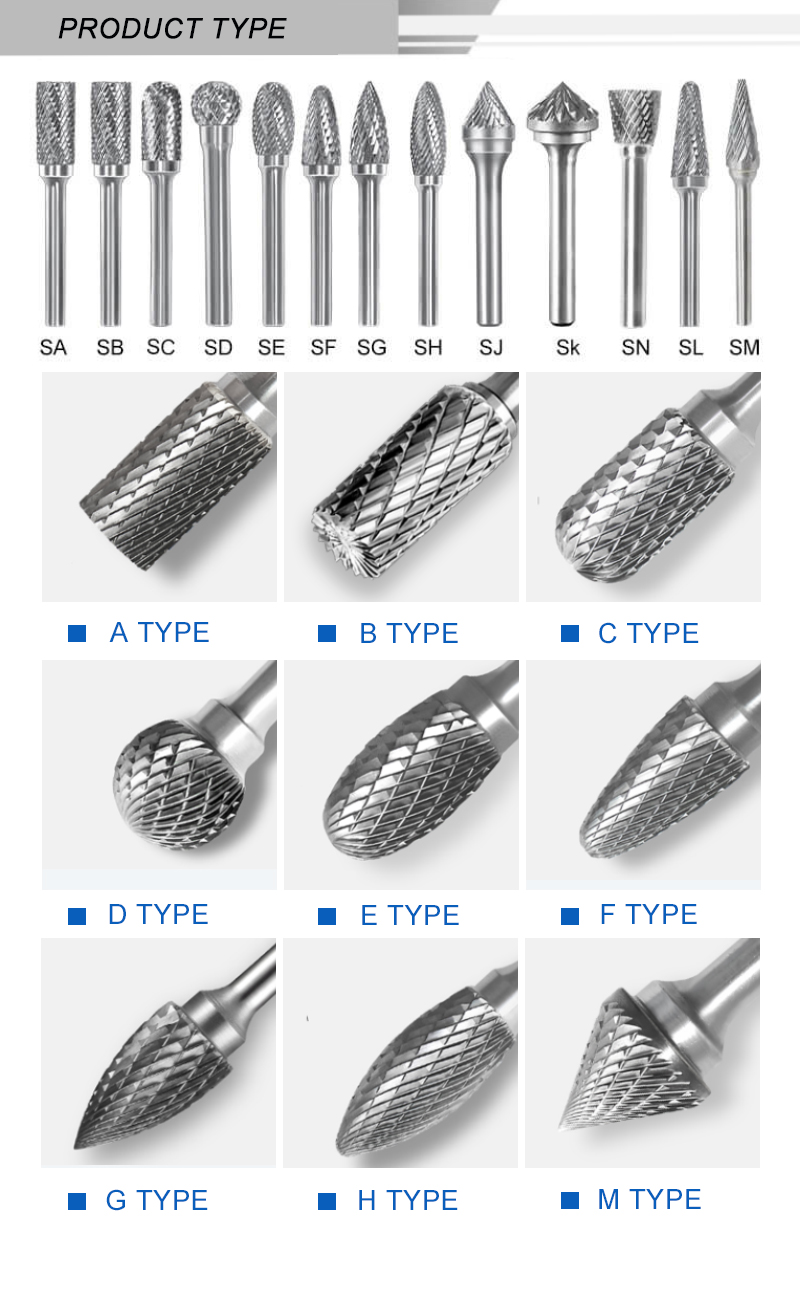

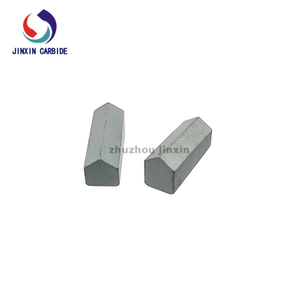

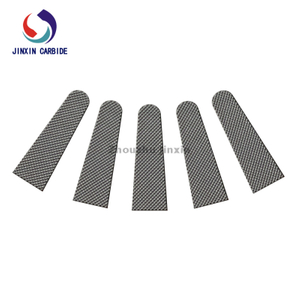

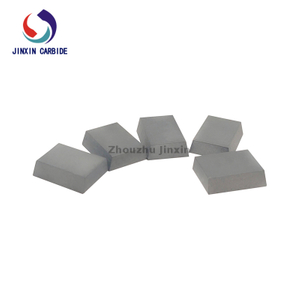

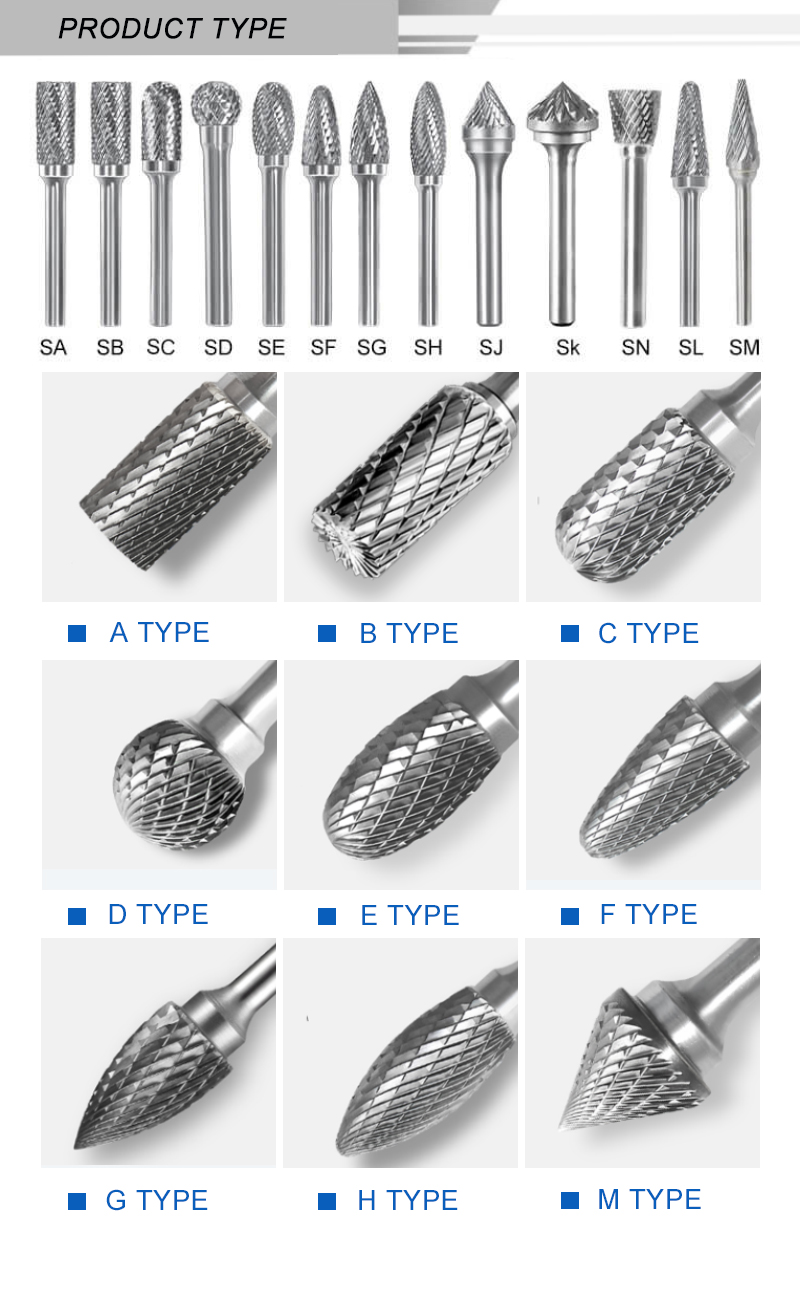

Different types of carbide burrs

JINXIN carbide burrs with great performance

Fast delivery

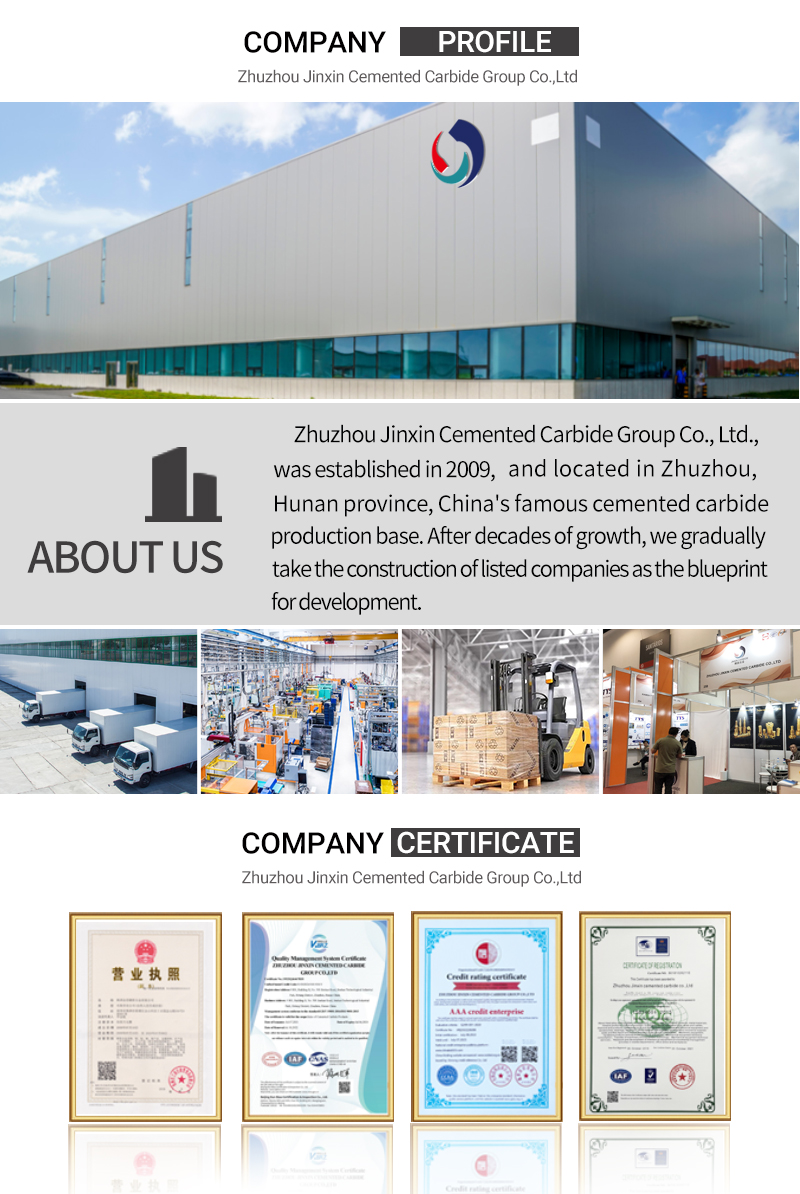

JINXIN using advanced equipment that purchased from Europe, we had build a automatic manufacture chain.

We have bulk of quantity store for the standard type of tungsten carbide rotary burrs, it can be delivered in 5 days after ordered.

Precision

JINXIN using high technical equipment have the capacity ensure all products in high precision standard.

Customized precision requirements is acceptable.

Cut type

Except standard singel cut, double cut, aluminium cut, we can aslo make other cut for different workpiece materials.

Our technician able to offer recommendation for all material suitable cutting.

Metric and Inch Size

We can supply both metric and inch size carbide rotary burrs for our customers. It is selectable according to different use requirements.

Please tell us your detail requirements before order.

+86-18073319589

+86-18073319589