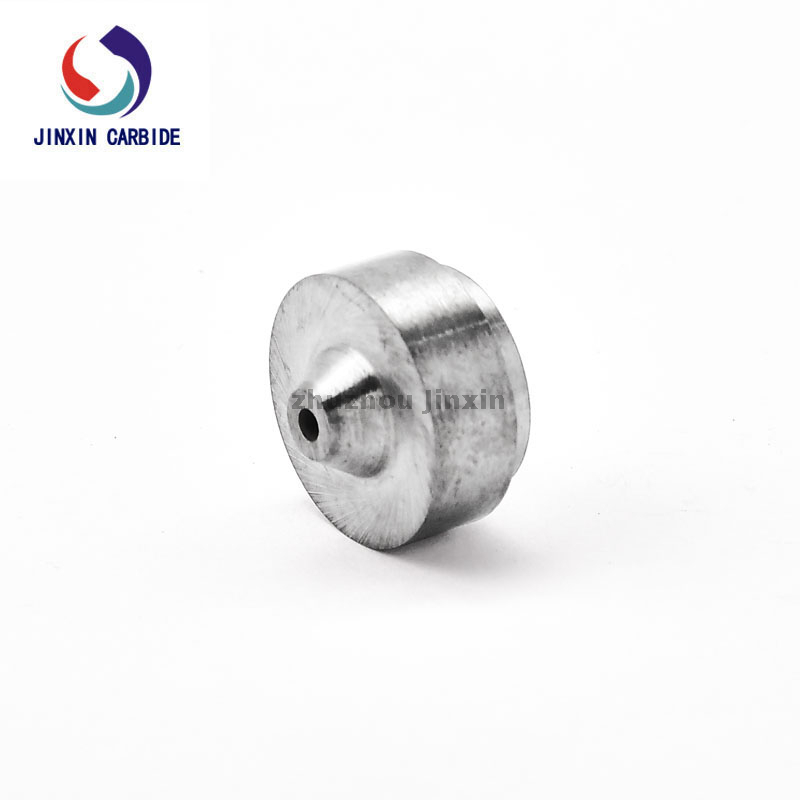

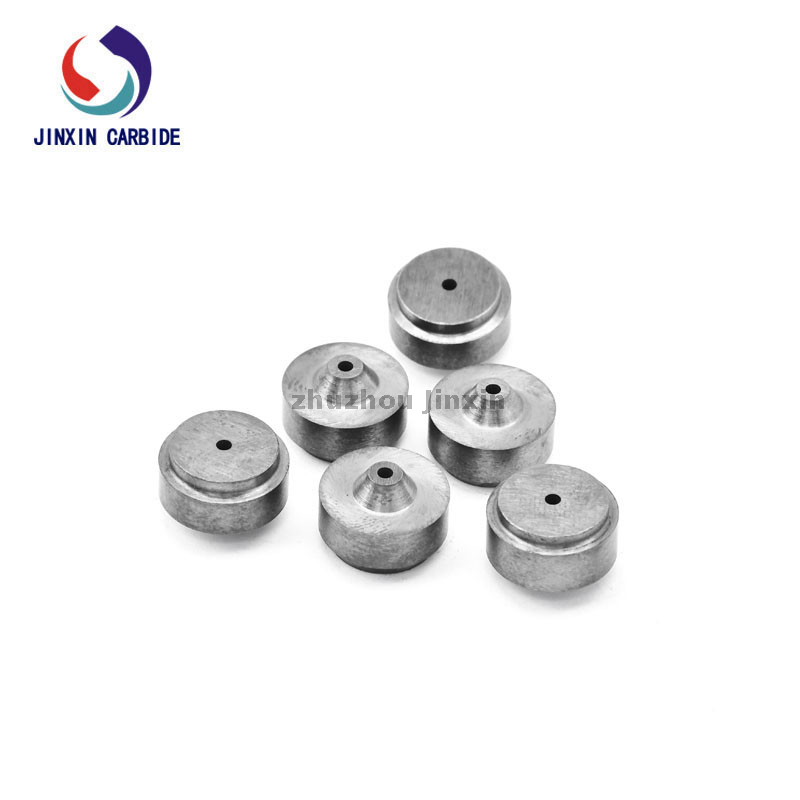

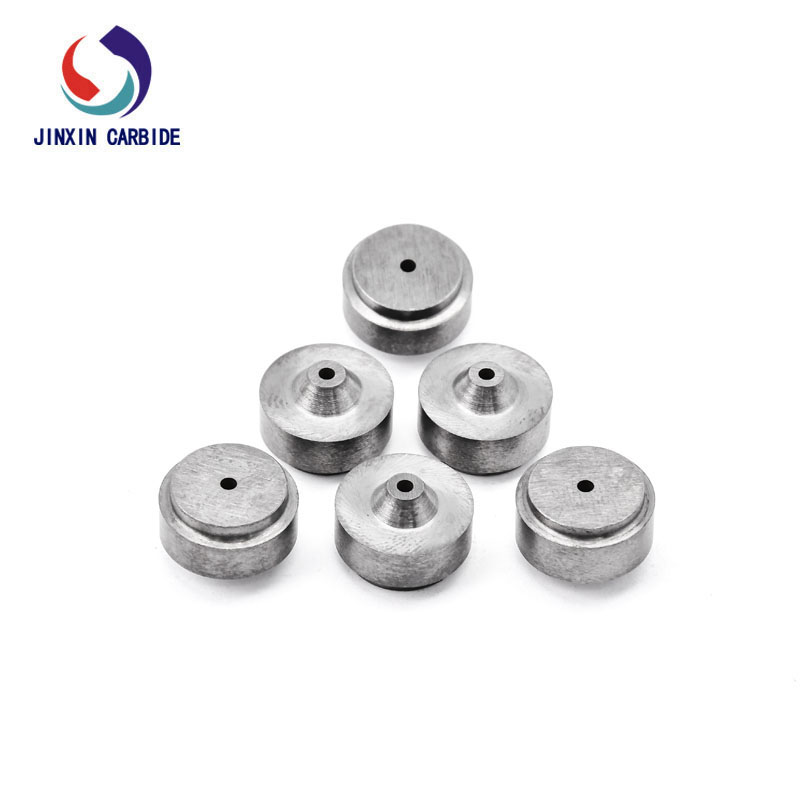

Tungsten Carbide Valve Seat description

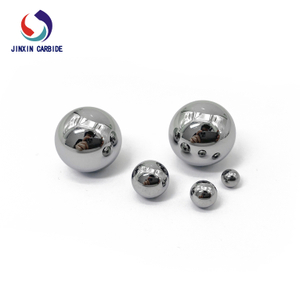

The role of the valve seat and valve ball is control the oil flow undirectionally, working medium includes gas, water oil, sand, wax, resin, asphaltene and other ingredients, which is a random variation of non homogeneous phase media. It is turned on and off alternately at a certain frequency cycle, extracted liquid carrying some mechanical impurities at a very high speed, violently washes the seat, and in the meanwhile, there is big impact between the seat, the ball and the cover in oil wells with large sand content, the sealing surface between the ball and the seat will be destroyed more quickly. At the same time, most oil wells have corrosion media, which is particularly corrosive to the valve seat.

The carbide valve seat has the features of anti-scour, wear and corrosion resistance, which can adapt better to the working conditions of the pump.

Tungsten Carbide Valve Seat Features

1. Anti-corrosion and wear resistant;

2. Long lifetime;

3. High pressure resistant;

4. High dimensional accuracy;

5. Excellent endurance to thrust load and high temperature

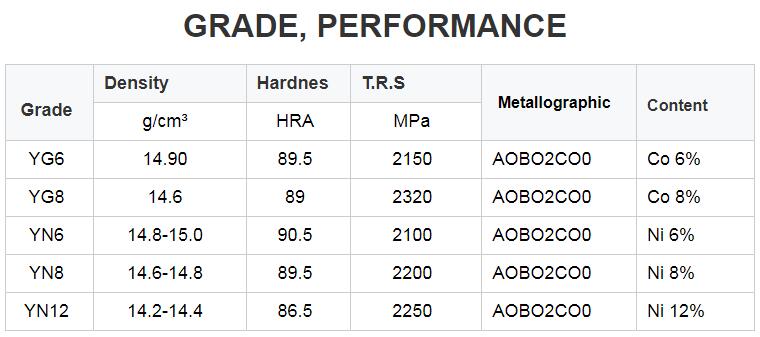

Tungsten Carbide Valve Seat grade & performance

+86-18073319589

+86-18073319589