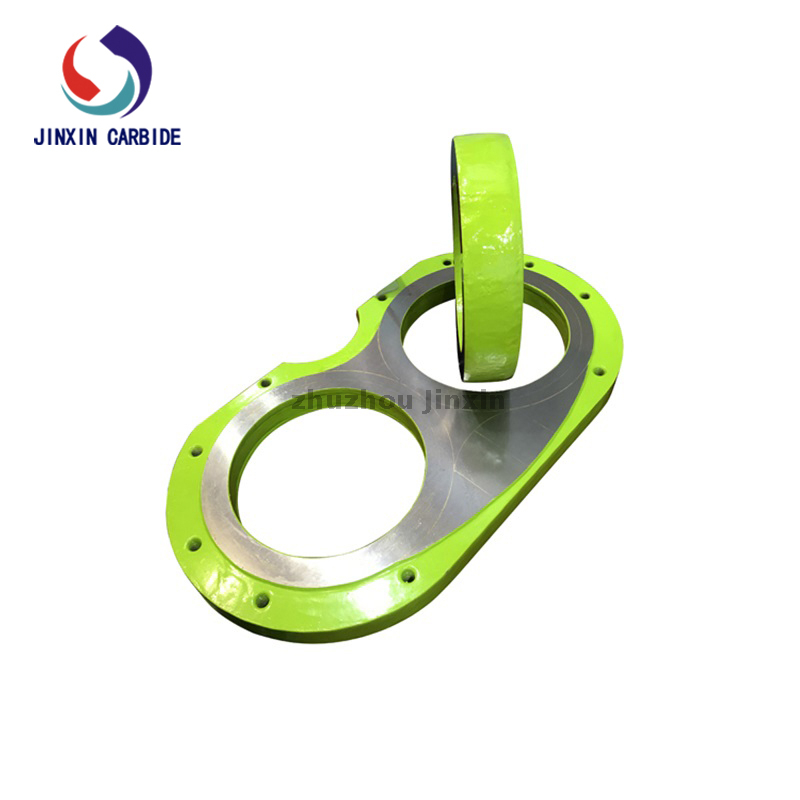

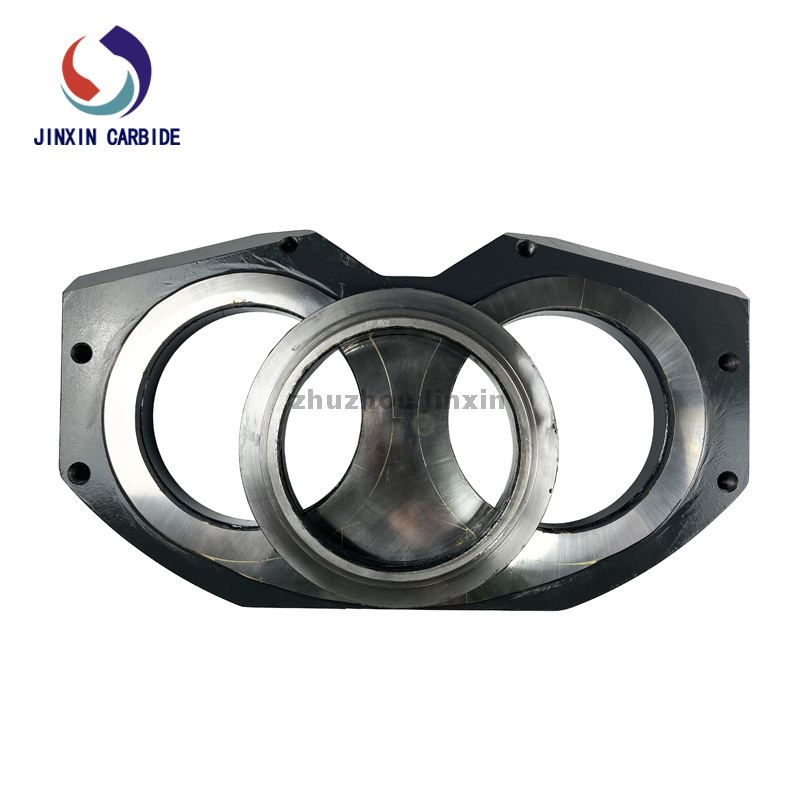

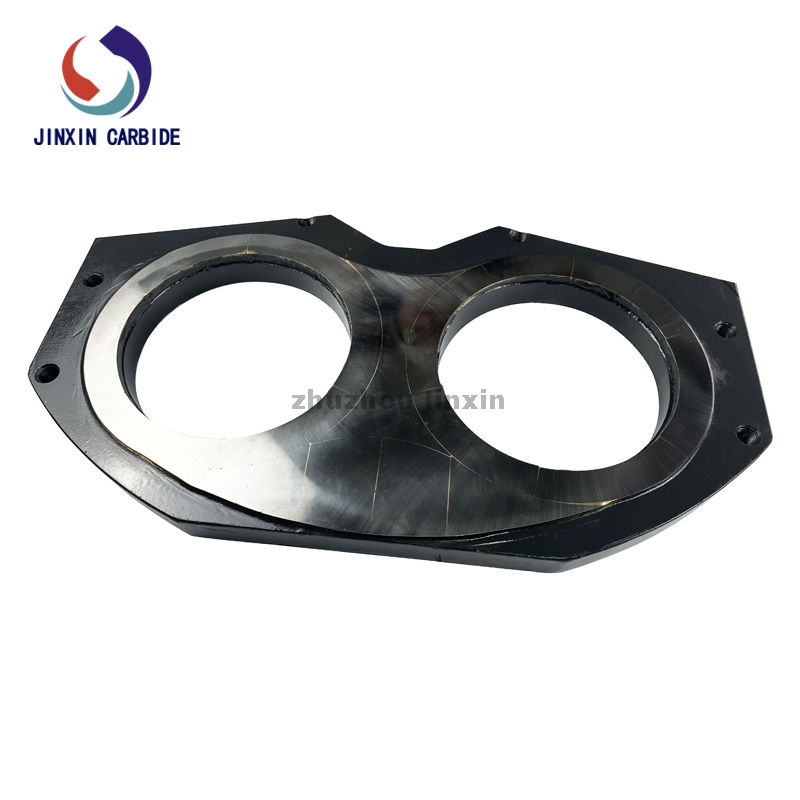

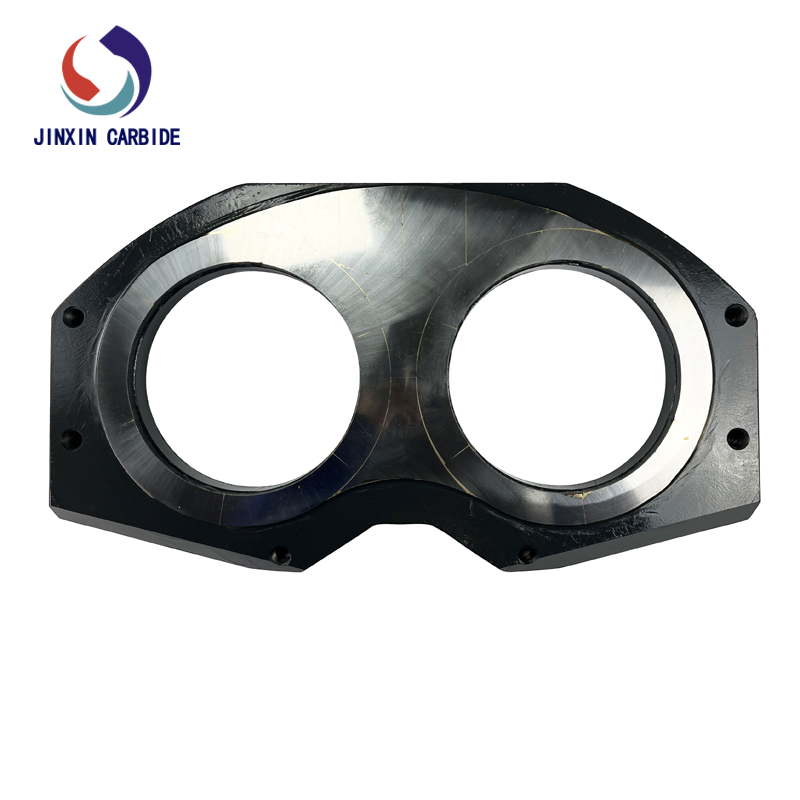

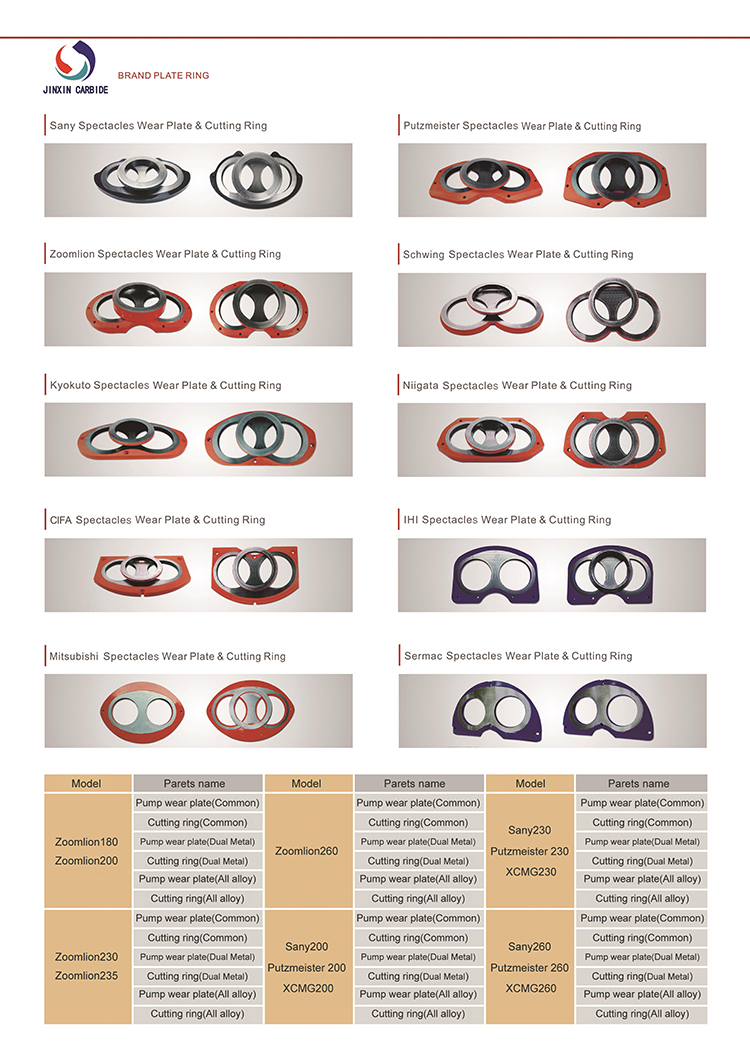

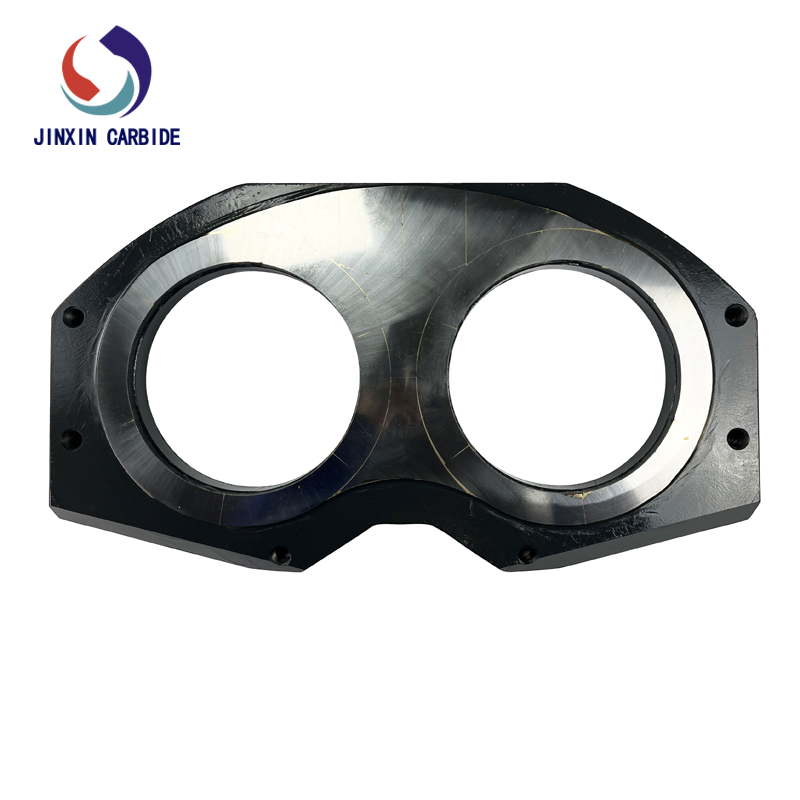

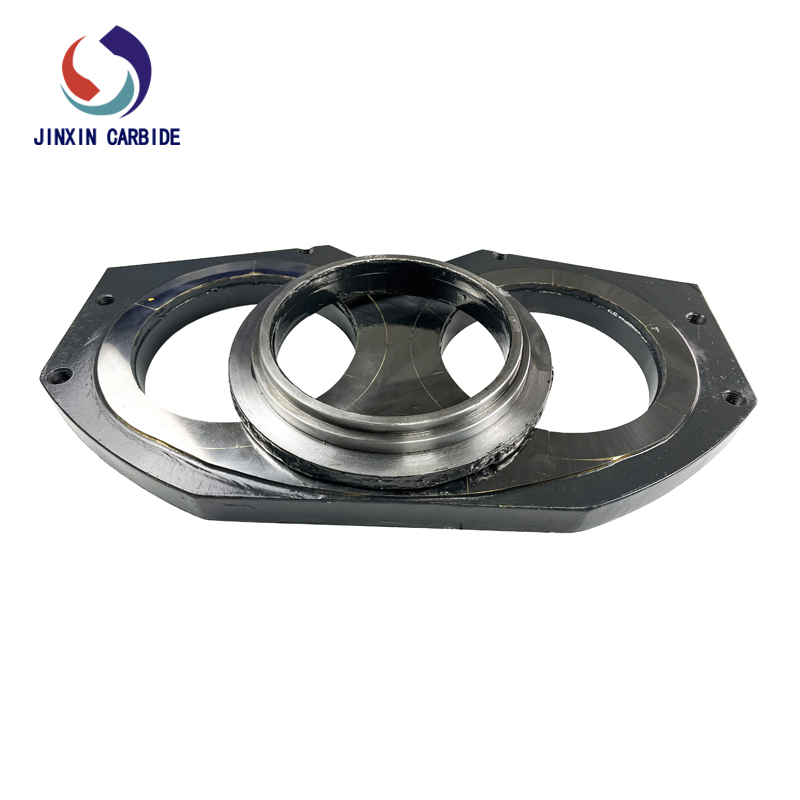

Concrete pump wear plate and cutting ring description

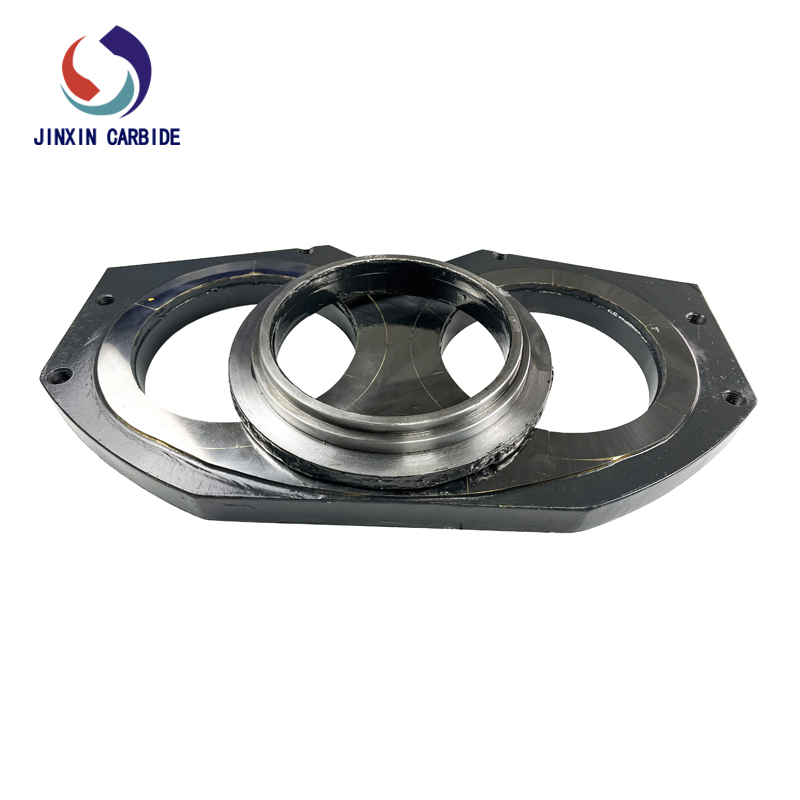

Wear plate, is a very important accessories of concrete pump machinery, because the shape like glasses, it is called glasses plate, cutting ring is also called wear-resistant ring, shaped like a circular ring, the working state is called cutting ring. The wer plate and the cutting ring are important parts of the fine stone concrete pump, and the role and use are the same.

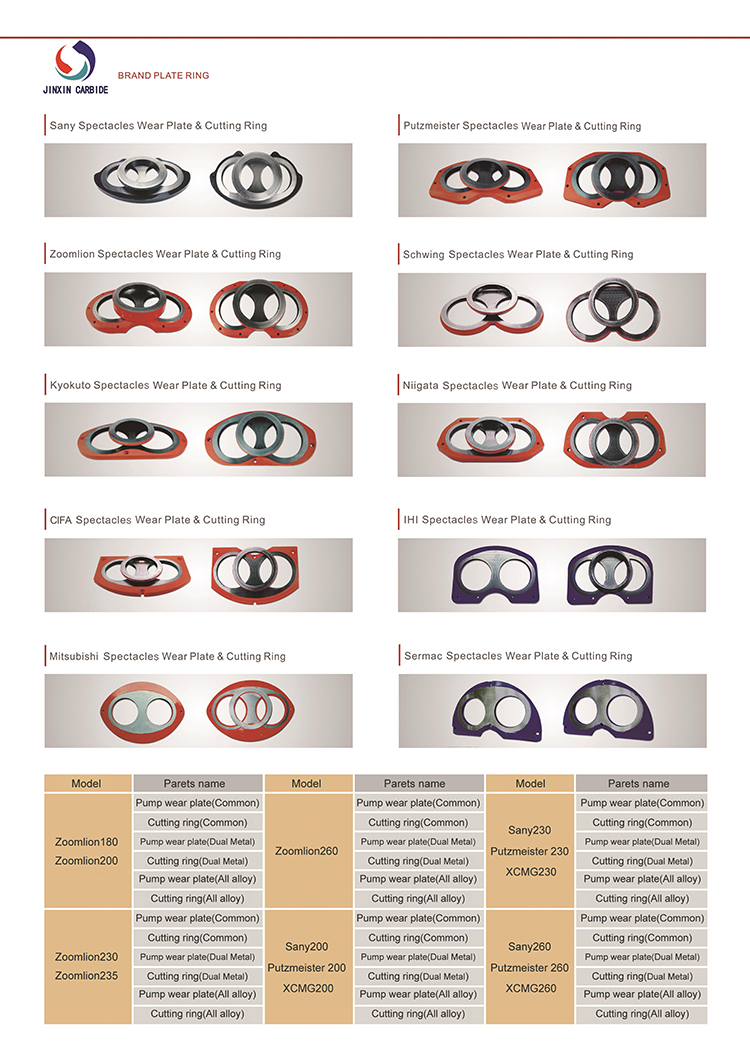

| Product name | concrete pump wear plate and cutting ring |

| Material | tungsten carbide ,steel plate,hardfacing material |

| Types | duro 22 type carbide type |

| Application | concrete pump hopper system |

| Brand available | putzmeister,schwing,zoomlion,cifa,sy,sermac.kcp,junjin,kyokuuto etc |

| Size | DN100/DN120/DN140/DB150/DN160/DN180/DN200/DN230/DN250/DN260 |

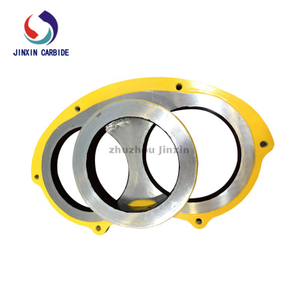

| Color | yellow, red, blue, black or other colors |

| Pumping lifetime | 10,000-100,000CBM depending on different designs and pumping situations |

To improve the service life of the wear plate and cutting ring, we must first start from the following aspects:

1. The ratio of concrete at each site is different, and there are differences, resulting in serious wear of wear plate and cutting ring. Therefore, it is necessary to increase the ratio of concrete as much as possible, so that the service life of the wear plate and the cutting ring can be longer.

2. There is a large gap between pumping conditions at each site. When the concrete is pumped at a large height and a long distance, the glass plate and the cutting ring will bear a lot of back pressure, resulting in a shortened service life. So try to reduce the conveying height and distance.

3. In addition, the incorrect installation of the wear plate and cutting ring makes there is a large gap between them, and the mortar will enter the gap during pumping, resulting in uneven friction of the glasses plate and cutting ring, damaging the contact surface and reducing the service life.

Different Brand of wear plate and cutting ring

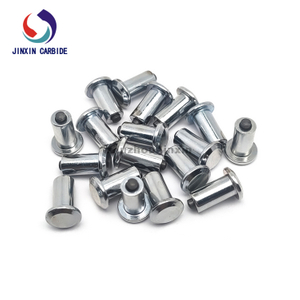

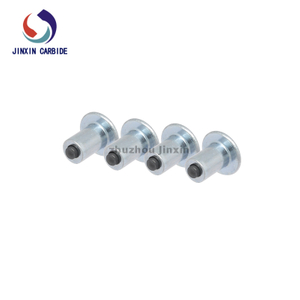

Wear plate and cutting ring photos

+86-18073319589

+86-18073319589